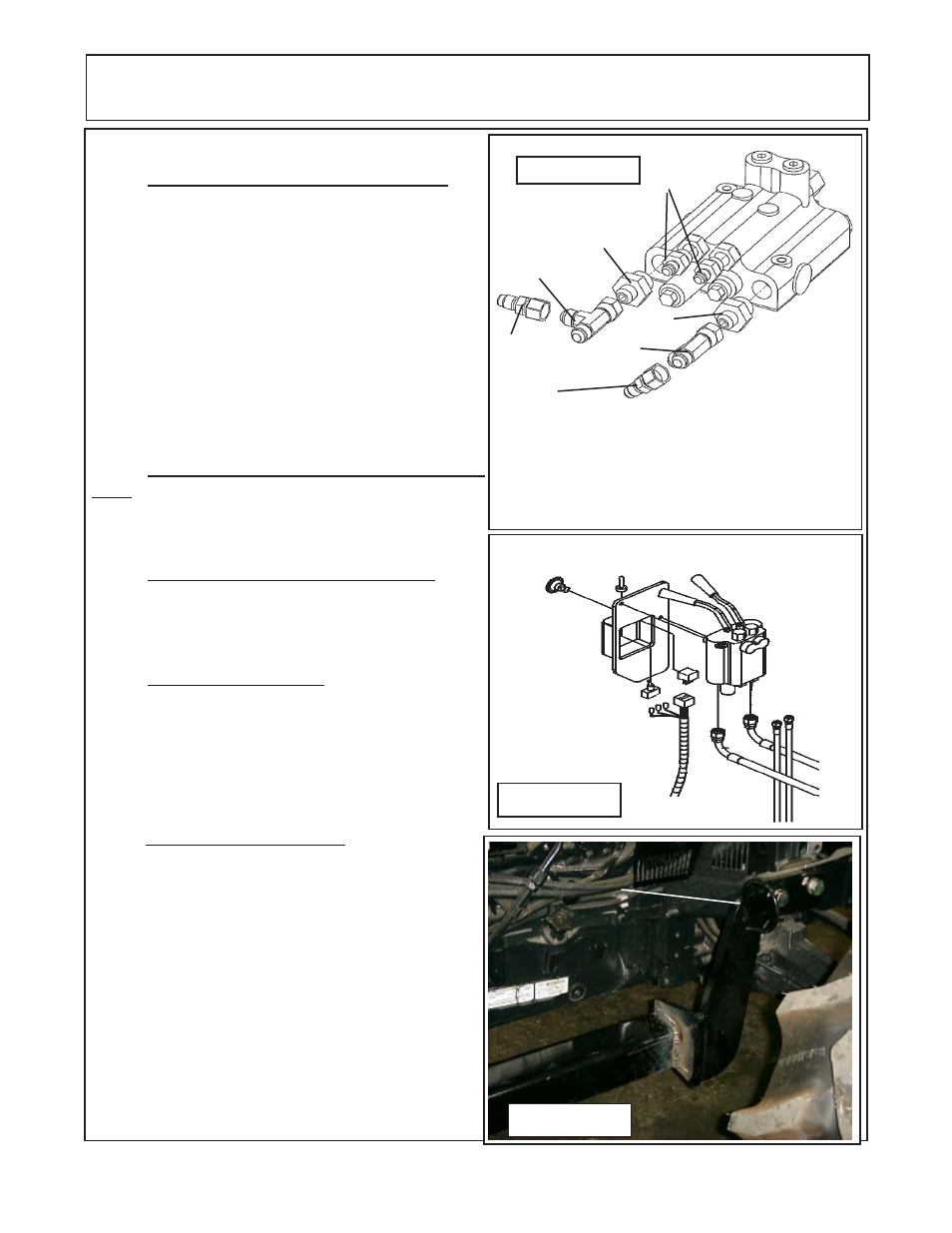

Hydrauliccontrol valve & hoses, Control valve & hoses, Figure 21 – Alamo JD-5225 User Manual

Page 47: Figure 22 figure 23

© 2005 Alamo Group Inc.

Section 5 - 9

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

5.

Install Electrical Switches. The electric neu-

tral safety switch and the head reversing switch both

mount into the valve mounting bracket (See Figure

22, and Electrical section in this assembly manual).,

Make certain that the battery cables are disconnected

before connecting any electrical connections, this is

to prevent the shorting of any components. Check the

tractors manufactures service /repair manual for any

restrictions or special instructions about connecting

electric components to the tractor.

HydraulicControl Valve & Hoses

Control Valve & Hoses:

1.

The two spool valve assembly shown (See

Figure 21) shows the fittings that are used on the two

spool control valve. Study the drawing. When working

on valve always clean the exterior of the valve and

hoses before disconnecting them. After disconnect-

ing the hoses cap them with clean caps to keep

contamination out of hydraulic system. When disas-

sembling the valve make certain the OD of it and all

work areas are clean, do not use dirty tools or rags that

will leave lint. Only lint free towels (paper or suitable

type) can be used to wipe down the hydraulic system.

If any components need to be held in the valve body

during assembly petroleum jelly can be used.

2.

When Connecting the hoses to the control

valve follow the directions as shown in the hydraulic

diagram (See Figure 26). Do not connect hoses

backward as this could damage the components.

3.

The control handle will connect direct to the

valve on ROPS Trctor (See Figure 23), the electric

reversing switch and components also connect to the

valve mount bracket as shown (See Figure 22).

4.

Install The Hose Holder. This will bolt on the RH

side of front bolster (See Figure 23). Looking at the

side of the tractor you will see 8 threaded holes, bolt

hose holder in the lower hole in second set back from

front (16 mm Hole) (See Figure 23). All hoses will be

run through sleeving material, this must be done

before they are connected.

Figure 21

Item Part No. Qty. Description

1.

02968850

2

Adapter,Straight 8MB - 6MJ

2.

03200284

2

Adapter,Straight 6MB - 4MJ

3.

02965166

2

Adapter,Tee 6FJX - 6MJ - 6MJ

4.

02982479

2

Adapter, Straight 4MB - 6FJX

1

2

3

4

2

3

4

Figure 22

Figure 23

P/N 02978281

Hose Ring

Weldment