Control valve & valve controls installation, Two spool control valve, Figure 1 – Alamo JD-5225 User Manual

Page 40

© 2005 Alamo Group Inc.

Section 5 - 2

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

Item

Part No.

Qty.

Description

02982077

--

Valve Asy. W/ Fittings

02974306

--

Valve Asy. W/O Fittings

1.

02976934

2

Unload Plunger

2.

02966645

2

Poppet Asy.

3.

02966646

1

Spacer

4.

02976933

2

Spool

5.

02966648

4

Seat Asy.

6.

02966649

2

Plug Asy.

7.

02966650

2

Plug Asy.

8.

02966651

2

Bushing

9.

02966652

2

Lockout Spring

10.

02966653

1

Cap Asy.

11.

02966654

1

Plug Asy.

12.

02976932

1

Body

13.

02976931

1

Poppet

14.

02976930

1

Seat

15.

02966657

4

O-Ring

16.

02966658

2

Retaining Ring

17.

02966659

A/R

Washer

18.

02966660

A/R

Washer

19.

02966661

A/R

Washer

20.

02966662

1

Washer

Item

Part No.

Qty.

Description

21.

02976946

1

Cap Asy.

22.

02976945

4

Spring

23.

02966669

1

Spring

24.

02976944

2

Plug Asy.

25.

02976943

1

Washer

26.

02976942

1

Washer

27.

02976941

3

Ball

28.

02976940

1

Spring

29.

02976939

1

Spring

30.

02976938

1

Cone

31.

02976937

1

Spacer

32.

02976936

1

Adapter Cap

33.

02976935

A/R

Washer

34.

02966671

2

Wiper Seal

35.

02976957

2

Handle Kit

36.

02968850

2

Adapter,Straight

8MB - 6MJ

37.

03200284

2

Adapter,Straight

6MB - 4MJ

38.

02965166

2

Adapter,Tee

6FJX - 6MJ - 6MJ

39.

02982479

2

Adapter, Straight

4MB - 6FJX

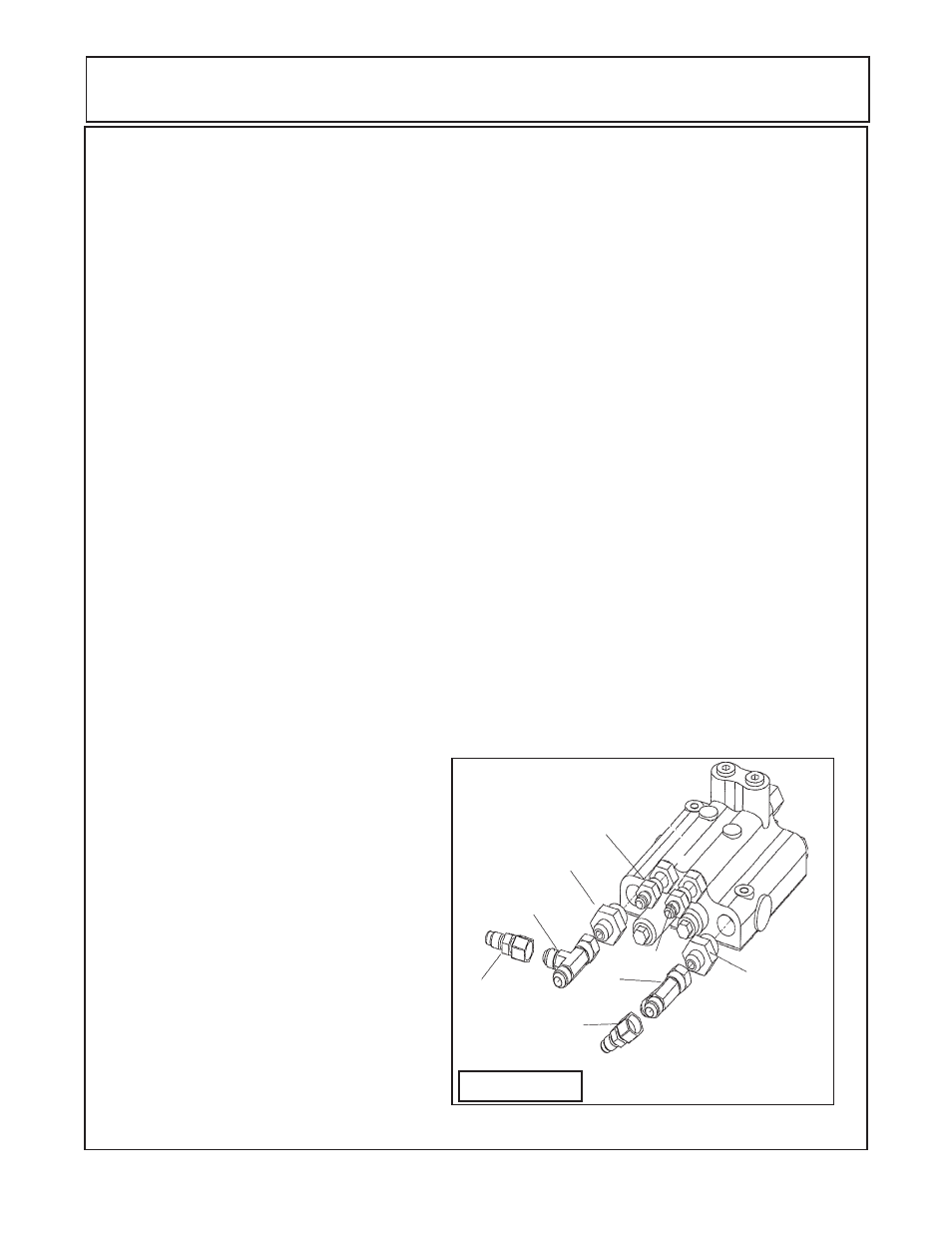

Two Spool Control Valve:

The two spool valve assembly shown (See Figure 13) shows the components that are

replaceable in the two spool control valve. Study the drawings, the torque specification if any are listed

for figure 12. The fittings are shown in figure

1 & 2. When working on valve always clean the

exterior of the valve and hoses before discon-

necting them. After disconnecting the hoses

cap them with clean caps to keep contamina-

tion out of hydraulic system. When disassem-

bling the valve make certain the OD of it and all

work areas are clean, do not use dirty tools or

rags that will leave lint. Only lint free towels

(paper or suitable type) can be used to wipe

down the hydraulic system. If any components

need to be held in the valve body during assem-

bly petroleum jelly can be used. DO NOT Ex-

ceed the recommended torque setting listed in

figure 12. When removing plug item 11 watch

the qty of washers that are removed, this amount

is what should be started with when reassem-

bling plug.

Control Valve & Valve Controls Installation

36

37

38

39

36

37

38

39

Figure 1