Cutter bar adjustments – Alamo JD-5225 User Manual

Page 58

© 2005 Alamo Group Inc.

Section 7 - 4

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

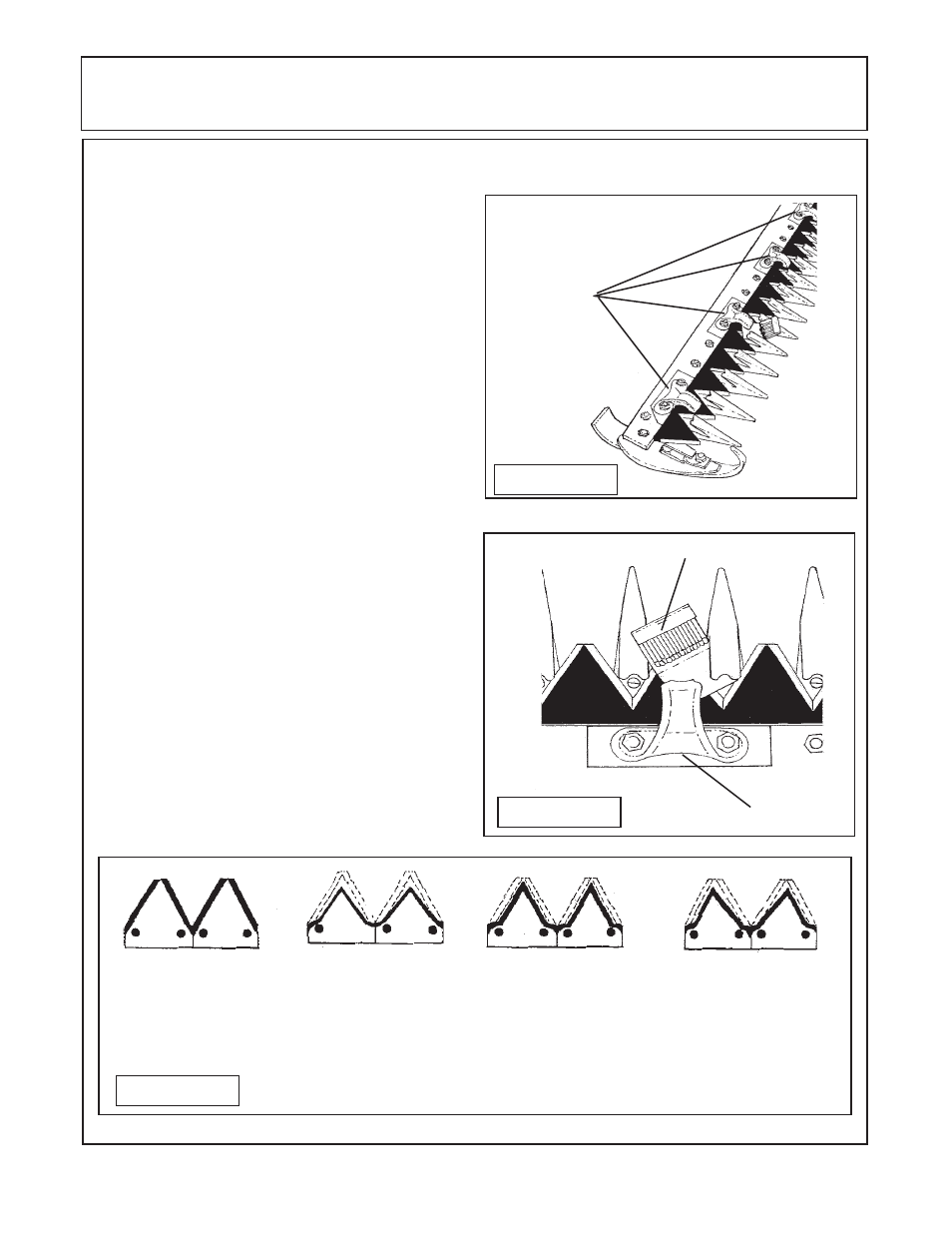

CUTTER BAR ADJUSTMENTS

Figure 7

Clips:

After all guards are adjusted, it is necessary

to see that the knife clips are bent down to within 1/

64" of the section. The easiest way to check this is

to hold the knife down on the ledger plate and use a

feeler gauge or the cover of a paper match book to

measure the clearance. Do not attempt to hold the

tightly against the ledger plate with the clips. Knock

the clips down with a hammer. A light blow with

hammer is all that is required. If the clips drag on the

knife, pry them up. Drag will bind the knife and wear

the clip very rapidly (See Figure 7 & 8).

Knife Repair:

ALWAYS USE A SHARP KNIFE. A dull knife

cuts poorly, may plug and doesn't do a clean job.

Keep the knife straight with the sections firmly

riveted to the knife back. When sharpening knife, be

careful to restore the original shear angle and bevel

of 23 °. Properly and improperly ground knife sec-

tions are shown (See Figure 9). A knife section that

has been ground several times may have the proper

angle and bevel and still be unserviceable because

the hard cutting edge has been ground away and the

section is to short to cut everything encountered.

Knife Replacement:

Replace worn or broken knife sections.

Alamo Industrial knife sections are heavy duty sec-

tions made of special steel and will stay sharp for

many more hours than conventional sections.

Figure 8

Clips

Clips

Match Book Cover

New Sections -

proper bevel and

angle for good work.

Improperly ground sec-

tions - narrow bevel

and wrong angle which

changes the angle of

shear.

properly ground sec-

tions even after re-

peated griding, proper

bevel and angle are

retained.

Sections ground off

center, destroying the

register of blade in

guard.

Figure 9