Using an adapter with a torque wrench, Figure 1 – Alamo JD-5225 User Manual

Page 13

© 2005 Alamo Group Inc.

Section 1 - 5

Switch Blade (JD-5105-5205-5225-5325-5425-5525, Asy. Man) 05/05

Figure 1

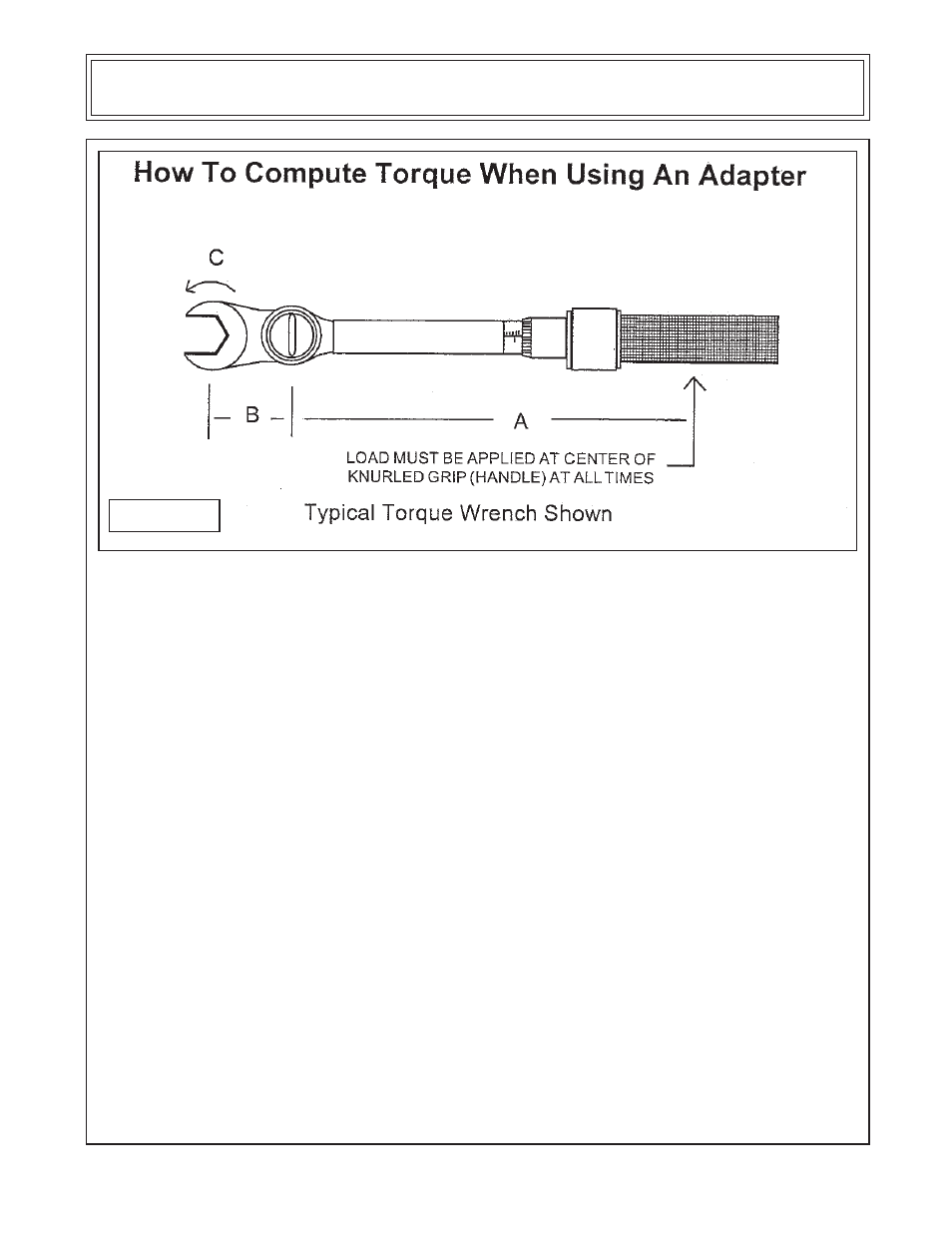

USING AN ADAPTER WITH A TORQUE WRENCH

If an adapter is attached to the drive of a torque wrench, the wrench will not give actual torque

indicated by the setting of the handle. A simple formula however, allows you to figure out what the

setting should be to deliver a predetermined amount of torque at the end of any adapter to the

fastener.

The following letters are defined as:

A

=

Length of the torque wrench when set at the middle scale setting (inches).

B

=

Length of adapter (inches from center hex bolt to center of torque wrench square shaft.

C

=

Desired torque at end of extrusion

D

=

Setting for accuracy within + or - 6%.

Here is a typical problem. You have an adapter that adds 10.0 inches to a torque wrench

length (dimension B) What should the setting be to obtain 320 ft. lbs. of torque at the end of the

adapter.

A

=

22.57 inches (length from adapter mounting point torque wrench to center of grip / handle)

B

=

10.0 inches (Length from adapter mounting point of torque wrench to center of hex slot).

C

=

320 ft. lbs. torque (desired torque at end of extension).

D

=

Unknown (setting you need to set torque wrench to = 320 ft. lbs for accuracy).

(A) (22.57) (22.57)

C

=

------------------- or 320 ----------------------- = 320 ------------------ = 320 X 222 ft. lbs.

(A + B) (22.57 + 10.0) (32.57)

Your Answer (D) is a setting of 222 ft. lbs. on the torque wrench will give 320 ft. lbs. of torque at the

bolt. By using the above formula an accuracy of + or - 6 % of the desired torque will result at the end

of the adapter due to length change during grip adjustment.