Commissioning, operation – WIKA DPGT40 User Manual

Page 15

GB

WIKA operating instructions differential pressure transmitter, model DPGT40

15

14093267.01 03/2014 GB/D/F/E

Measuring assemblies

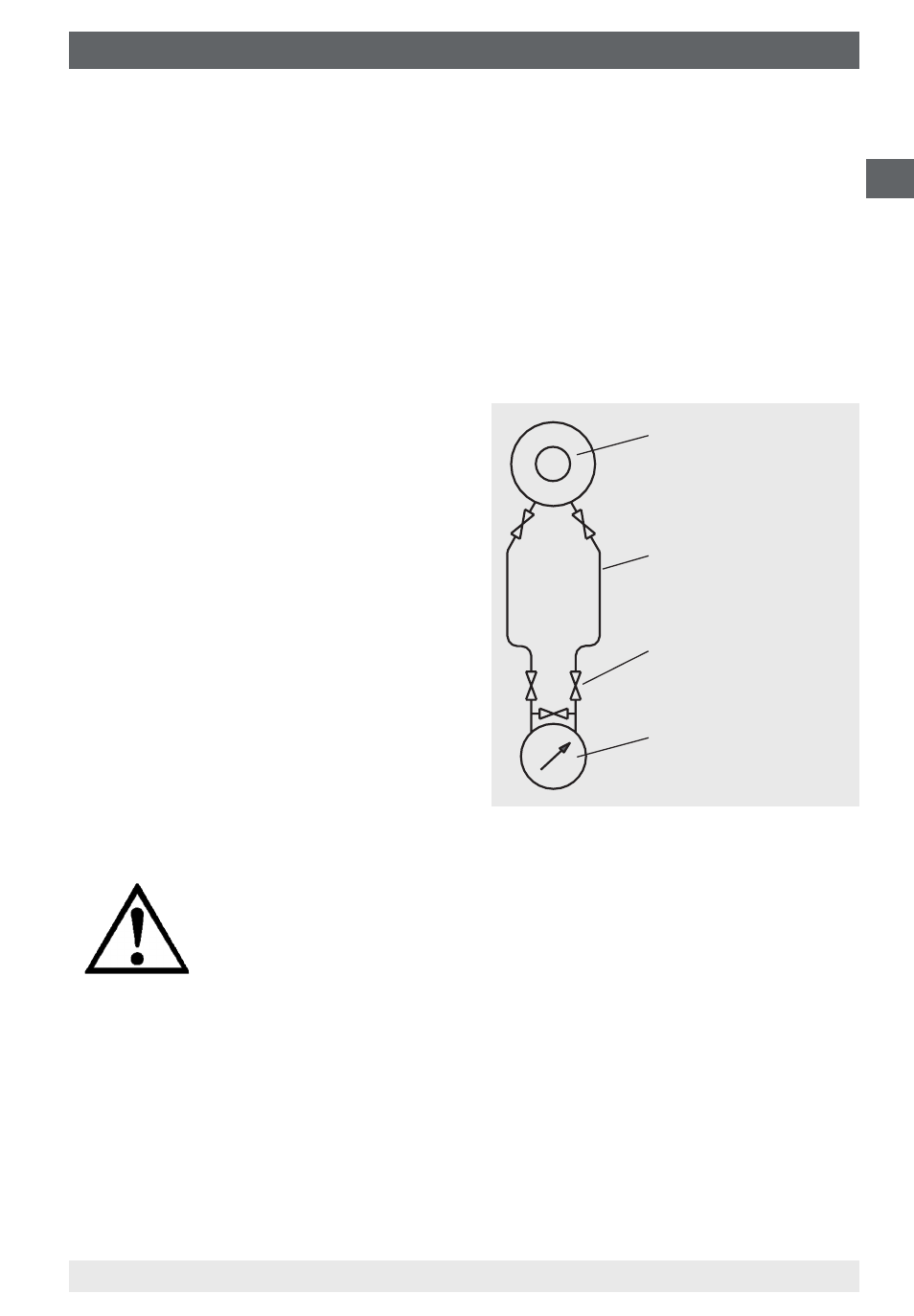

The preferred measuring assemblies for various possible applications are

specified in DIN 19216.

The following schematic diagram shows a recommended assembly for liquid

media. As throttling devices, differential pressure transducers should be provided

in accordance with DIN 1952 (issue 07.82), now replaced by EN 5167/1.

The differential pressure lines must be made from metal, their bore must not

be less than 4 mm and the effective length between the valve manifold and the

differential pressure transmitter must be at least 500 mm.

Differential pressure

transducer

(throttling device in the

process line)

Differential pressure

instrument

(DELTA-trans)

Shut-off valves

(valve manifold)

Differential pressure

line

6. Commissioning, operation

In addition, the length and the bore of

the pressure lines should be such that,

with cold lines, the response time of

the pressure gauge is not more than

5 seconds.

The connections of the differential

pressure lines must be welded, brazed or

screwed using metal sealing elements.

Shut-off valves in differential pressure

lines must only be operated using tools.

Safety instructions for installation

■

Follow the installation and safety instructions within the

operating instructions.

■

Install instruments in accordance with the manufacturer's

instructions and the valid standards and regulations.

■

The instruments do not provide for incorporated overcurrent protectors!

Once the pressure connection and the electrical connections have been made,

the pressure transmitters are ready for immediate use.

Commissioning

During the commissioning process pressure surges must be avoided at all costs.

Open the shut-off valves slowly.