Installing your mobile base - method 2, 11 sawstop professional cabinet saw mobile base, Fig. 1 – SawStop Mobile Base User Manual

Page 13

11

SawStop Professional Cabinet Saw Mobile Base

Installing Your Mobile Base - Method 2

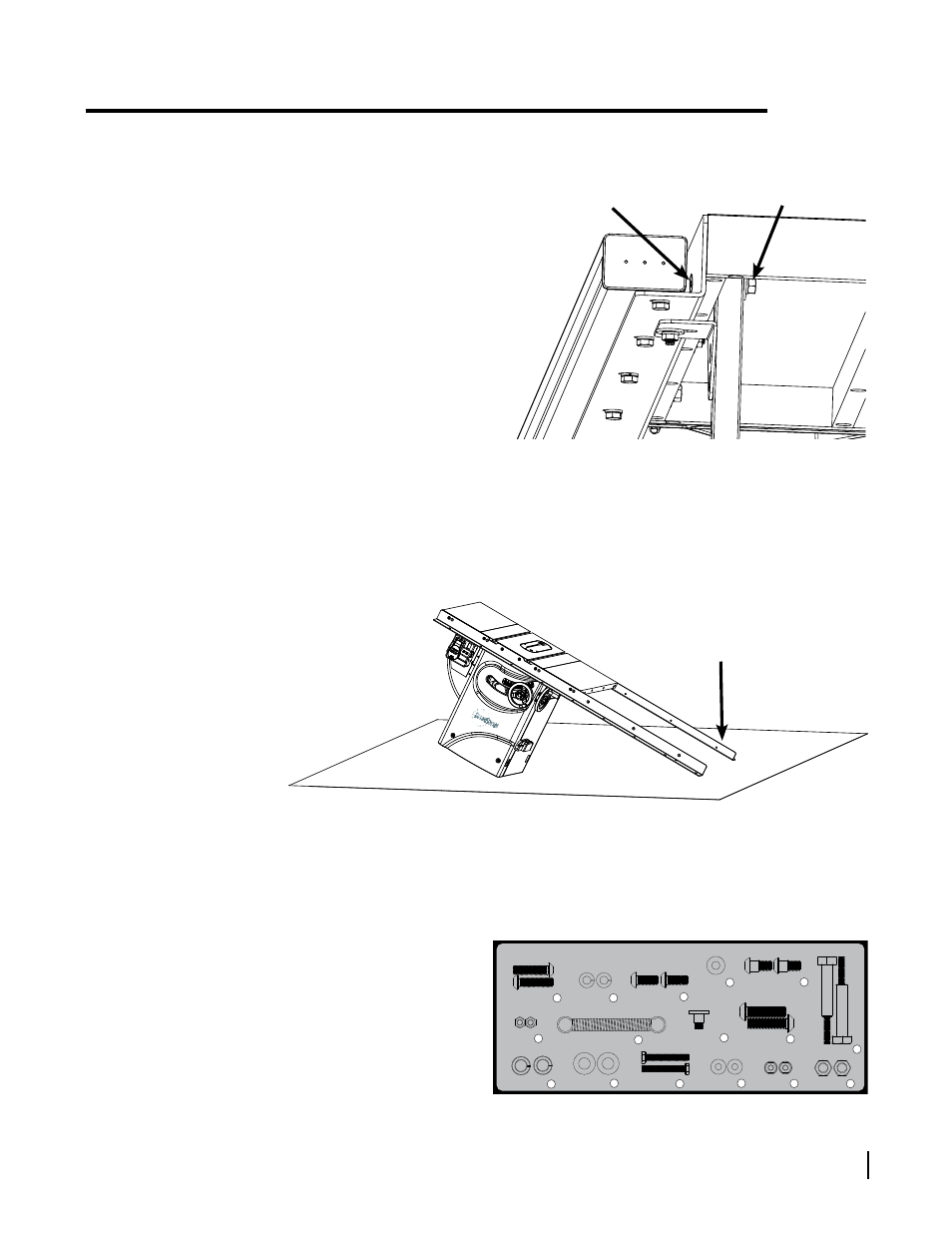

3. Loosen the M8 x 65 countersunk socket head bolt

that mounts the front leg to the front rail, but do not

remove the bolt or nut. Use the 5 mm short-arm hex

key supplied with the mobile base to keep the bolt

from turning while you loosen the nut with a 13 mm

wrench (see Fig. 1). The 5 mm short-arm hex key

is sized so that it can engage the head of the bolt

without having to remove the front rail tube. Repeat

the procedure to loosen the M8 hex nut on the back of

the M8 x 65 countersunk socket head bolt that mounts

the rear leg to the rear rail. Rotate the end of each

support leg toward the saw so that both support legs

are out of the way and the saw can be tipped onto its

side.

Fig. 3

5. Locate all of the mobile base components shown on page 1. All of the hardware needed to install the mobile

base is located on the hardware pack (see Fig. 3). In order to easily identify the hardware used in each of

the following steps, the different pieces of hardware are numbered on the hardware pack and in the figures.

If you are missing the hardware pack or any of the other mobile base components, call the SawStop Service

Department at 503-582-9934 for replacements.

You will need the following tools to complete the

mobile base installation:

• a 5 mm hex key

• a 6 mm hex key

• a 10 mm socket

• a 10 mm wrench

• a 14 mm wrench

• a 17 mm wrench

Professional Cabinet Saw Mobile Base Hardware Pack

Extension Spring, (1)

8

Lock Washers,

M8 x 13.6 (4)

2

Washers,

M8 x 18 (2)

4

Washers,

M6 x 16 (2)

14

Flange Lock

Nuts, M6 (2)

15

Hex Bolts,

M6 x 40 (2)

13

Lock Washers,

M10.5 x 17 (4)

11

Caster Nuts,

3/8” thread (2)

16

Button Head Socket

Bolts, M8 x 35 (2)

1

Lock Nuts,

M6 (2)

7

Shoulder Socket

Screw, M8 x 17.7 (1)

9

Button Head Socket

Bolts, M10 x 40 (2)

10

Washers,

M10.5 x 20 (4)

12

Button Head Socket

Bolts, M8 x 20 (2)

3

Button Head Shoulder

Socket Bolts, M8 x 20 (2)

5

Fixed Wheel Axles

6

Fig. 1

loosen the M8 hex nut

enough so that the

support leg can rotate

use the 5 mm short-arm

hex key to keep the bolt

head from rotating

4. With the front and rear rails are securley mounted, any out-feed table removed, and the extension table legs

removed or rotated out of the way, the saw can be tipped to the side. To make the saw easier to tip, adjust the

tilt handwheel until the blade is set at 45° to the table. Make sure the saw is on a level surface and then, with

the help of an assistant, grip the sides of the rails near the ends and push down to gently lower the rails to the

ground (see Fig. ). Do not grip an extension table or the end of the rails to lower the saw to the tipped position

because you might pinch your fingers between the extension table or rails and the ground. The rear rail is

shorter than the front rail and typically

will not touch the ground. To prevent

scratching the rails, you can set the

edge of the front rail on a piece of

cardboard or cloth.

Fig.

push down on the rails and gently

lower the saw to the tipped position