Adjusting your t-glide fence system – SawStop T-Glide Fence System User Manual

Page 24

Adjusting Your T-Glide Fence System

It is usually possible to adjust the position of the face

plates by placing a small block of wood against the top

or bottom edge of the face plates, and then tapping the

block of wood with a plastic or wooden mallet. However, if

the face plates do not move when tapped, you can loosen

the mounting screws as described below to adjust the

face plates.

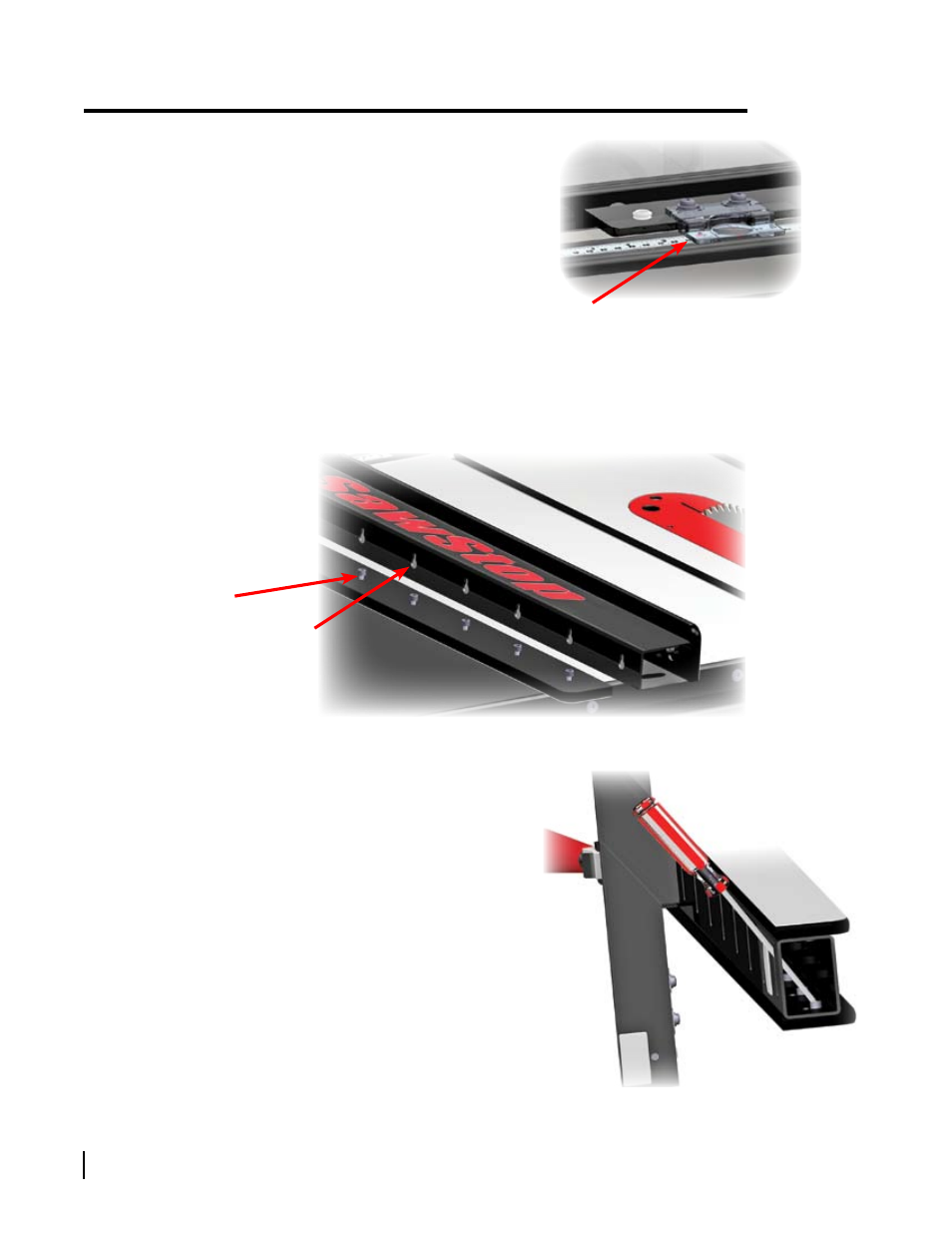

You can access the screws that attach the face plates to

the fence through the slots on the bottom of the fence.

Insert a 5 mm ball-end hex driver through the slot at the

end of the fence and into the screw head (see Fig. 30 with

endcap removed). Loosen the screw about one-quarter

to one-half turn. Do not loosen the screw too much. The

screw should be just loose enough to allow the plate to

move but still tight enough to hold the plate temporarily

in its new position. Continue this process with each slot/

screw pair. Once all the screws on one face plate are

loose, slide the face plate toward the top of the fence.

The last step is to set the spacing between the bottom of each face plate and the table. The face plates are

held in place by a series of screws threaded into nuts embedded in the face plates. The heads of the screws

fit into key-hole slots in the sides of the fence (see Fig. 29 with endcap removed).

key-hole

slot

screw

head

Fig. 29

You may find that after adjusting the face plates

the end of the cross-bracket has been raised or

lowered such that it is too close or too far away

from the main tube. If this is the case, turn both

plastic leveling screws the same amount in order

to ensure the position indicator lenses are close,

but not touching the front tube or rulers.

There should be a gap between the position

indicator lens and the ruler on the main tube.

Fig. 28

22 SawStop T-Glide Fence System - Professional Series II

Fig. 30