Installing your t-glide fence system, Contractor saw – SawStop T-Glide Fence System User Manual

Page 12

Made in T

aiwan

SawStop,

LLC

www.saw

stop.com

TCP

10¨ Cont

ractor Saw

SawStop

®

Model No. CNS 175

Serial No. C0740

12345

Electrical / Electricid

ad / Électricité

115/230 V

olts, 60 Hz

15/7.5 Am

ps

1 Phase

1.75 HP

3500 RPM

®

c

US

175370

Moving

belts and pa

rts

can pinch

, cut or c

rush.

Do not o

per

ate with

belt gua

rd o

pen.

rear rail

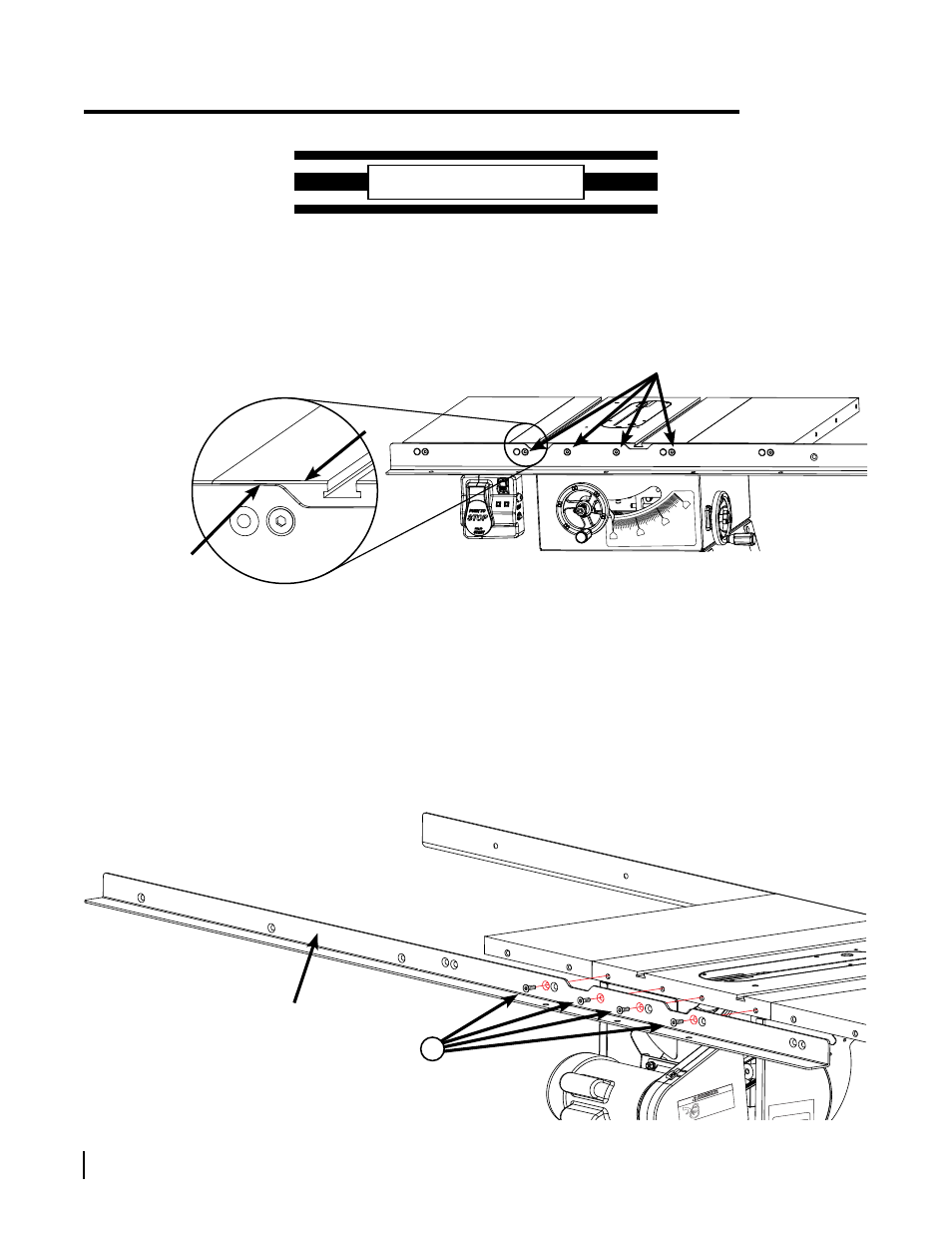

4. Begin mounting the rear rail (the shorter of the two rails) to the rear edge of your saw by centering the notches

in the rail with the two miter slots in the table and aligning the left-most hole between the notches with the

corresponding hole in the rear edge of the table. There are three holes in the rail between the notches, one

solitary hole and two holes paired together, and the left-most hole is the solitary hole. Not all the holes are used

to mount the rail to your saw; different holes are used for different saws. Aligning the left-most hole aligns all

the other holes used in mounting the rail to your saw. When the holes are aligned, mount the rail to the saw

by threading an M8 x 16 countersunk socket head bolt into each of the four open holes in the rear edge of the

table and tighten the bolts using a 5 mm hex key (see Fig. 4).

Fig. 4

Contractor Saw

1

10 SawStop T-Glide Fence System - Professional Series II

Installing Your T-Glide Fence System

0

15

30

45

SawStop

10” Contractor Saw

level the top of

the front rail with

the lower edge

of the bevel

bevel

tighten

Fig. 3

3. The holes in the front edge of the table and extension wings are slightly larger than the bolts they receive to

allow you to level the front rail and extension wings to the table top. Align the top of the front rail with the lower

edge of the bevel on the front edge of the table top (see Fig. 3). Use a 5 mm hex key and a 13 mm wrench to

fully tighten the nuts on the back of the four bolts that extend through the table top. Do not tighten the nuts on

the bolts that extend through the extension wings.