Mittler Bros Machine & Tool 1000-RENK1 REAR END NARROWING KIT User Manual

Page 2

CUTTING

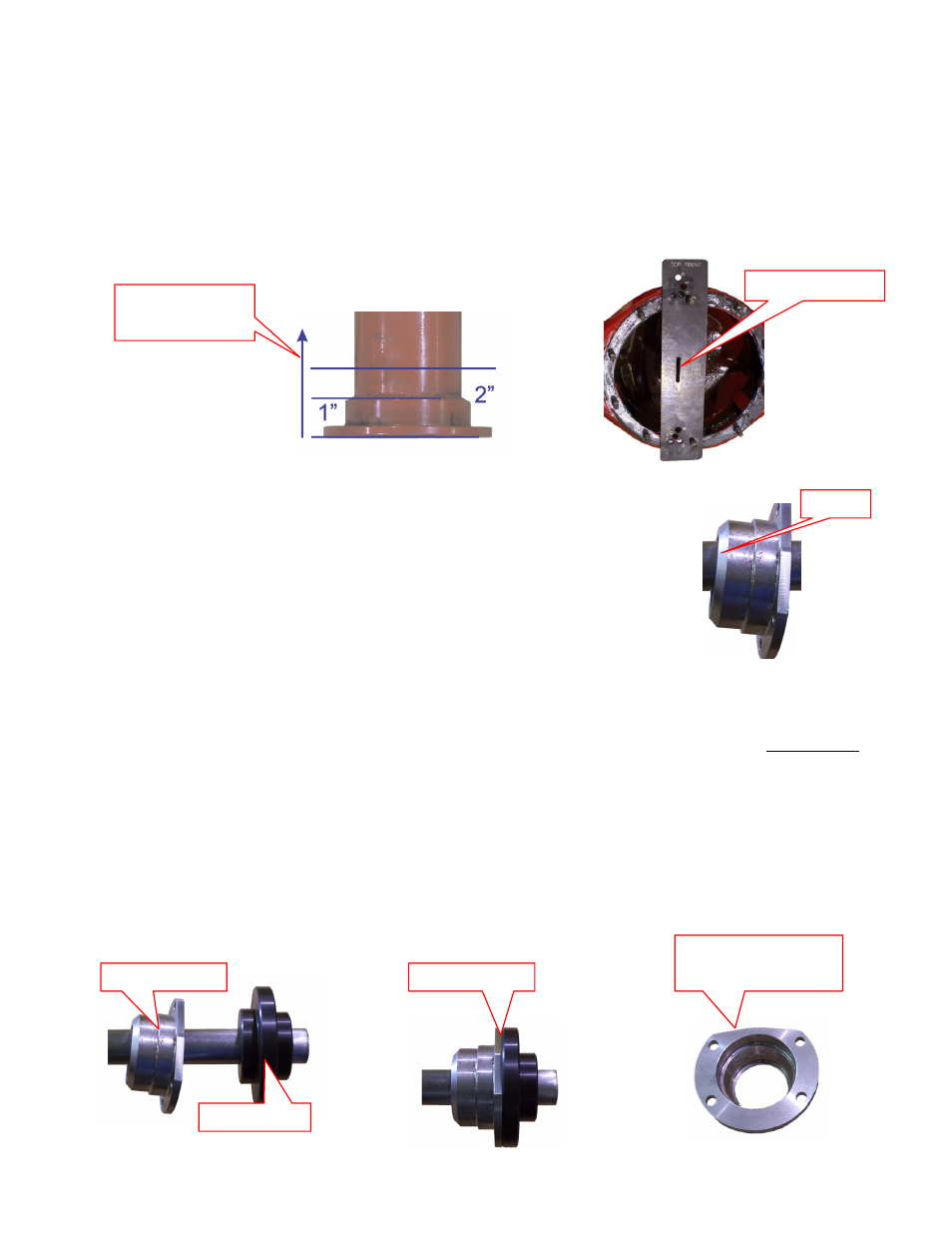

3. After you have determine the desired width, pinion offset and cut locations using the supplied

work sheet you are ready to cut the ends off of your housing. We recommend cutting the

exsisting ends off close to the bearing end between 1” & 2” back from the flange. If there are

seals in the end be sure to cut behind them. The best cuts will be made with a

HORIZANTAL

BAND SAW or a CHOP SAW.

4. Bevel the housing tubes and the housing ends. This will assure a

quality weld joint. The amount of bevel will be determined by the

welding method, MIG or TIG. MIG will require a larger bevel than TIG.

POSITIONING

5. Slide the bar into the housing and through the inner alignment pucks. Be careful not to jam the

bar into the pucks as this may knock them loose or out of alignment. On “Drop Out” style

housings, be sure the carrier assembly is bolted into the housing with a gasket.

6. Slide the housing end onto the shaft followed by the appropriate outer line up puck. Slip the puck

into the housing end and then slide the assembly up to the end of the tube. Be sure to orient the

housing end correctly in relation to the housing. Check that the bolt pattern is aligned correctly for

the brakes you will be using.

Pinion Centerline

Housing End

Cut 1” or 2” back

from end.

Bevel

Outer Puck

Slip Together

Check Bolt Pattern

Check For Top