Pre-assembly inspections, Replacement guidelines, Placement guidelines – Goulds Pumps VIC - IOM User Manual

Page 56

Use an arbor press and a piece of pipe or sleeve with an outside diameter that is slightly smaller than

the diameter of the bowl or lineshaft bearing housing bore.

2. Remove the suction bell bearing by setting the suction bell in a lathe and machining the bearing off.

The suction bell bearing can also be removed using bearing pullers to pull the bearings out.

Pre-assembly inspections

Guidelines

Before you assemble the pump parts, make sure you follow these guidelines:

• Inspect the pump parts according to the information in these pre-assembly topics before you

reassemble your pump. Replace any part that does not meet the required criteria.

• Make sure that the parts are clean. Clean the pump parts in solvent in order to remove oil, grease, and

dirt.

NOTICE: Protect machined surfaces while you clean the parts. Failure to do so may result in

equipment damage.

Replacement guidelines

Casing check and replacement

Inspect the casing for cracks and excessive wear or pitting. Thoroughly clean gasket surfaces and alignment

fits in order to remove rust and debris.

Impeller replacement

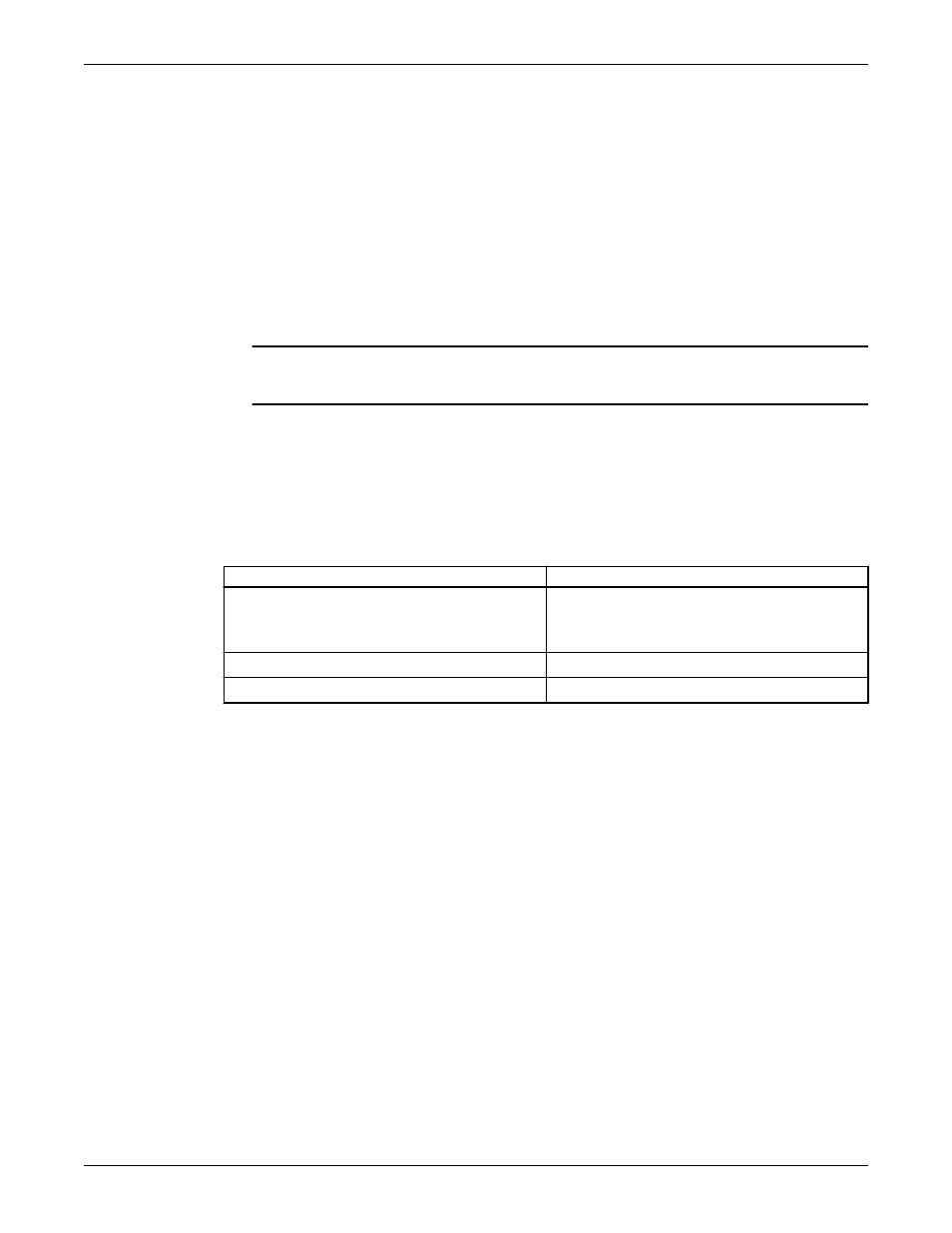

This table shows the criteria for replacing the impeller:

Impeller parts

When to replace

Impeller vanes

• When grooved deeper than 1/16 in. (1.6 mm),

or

• When worn evenly more than 1/32 in. (0.8 mm)

Vane edges

When you see cracks, pitting, or corrosion damage

Keyway and bores

When you see damage

Gaskets, O-rings, and seats replacement

• Replace all gaskets and O-rings at each overhaul and disassembly.

• Inspect the seats. They must be smooth and free of physical defects.

In order to repair worn seats, skin cut them in a lathe while you maintain dimensional relationships

with other surfaces.

• Replace parts if the seats are defective.

Bearing retainer check

Check the bearing retainer for deformation and wear.

Mechanical seal checks

On pumps equipped with a mechanical seal, check that the shaft or sleeve is free of pits, burrs, or sharp

edges in order to prevent cutting or improper sealing of the seal O-rings. Remove any burrs and sharp

edges by polishing with a fine emery cloth.

Impeller and bowl checks

Visually check impellers and bowls for cracks and pitting. Check all bowl bearings for excessive wear and

corrosion.

Maintenance (Continued)

54

Model VIC Installation, Operation, and Maintenance