Adjust the impeller for a hollow-shaft driver – Goulds Pumps VIC - IOM User Manual

Page 45

Adjust the impeller for a hollow-shaft driver

NOTICE:

• If your hollow-shaft driver has a mechanical seal, you must disengage it prior to impeller adjustment.

• Improper impeller adjustment can cause contact between the rotating and stationary parts. This

results in sparks and heat generation.

This procedure applies to the open and enclosed impeller:

1. Make sure that the shafting is all the way down and that the impellers are resting on their seats.

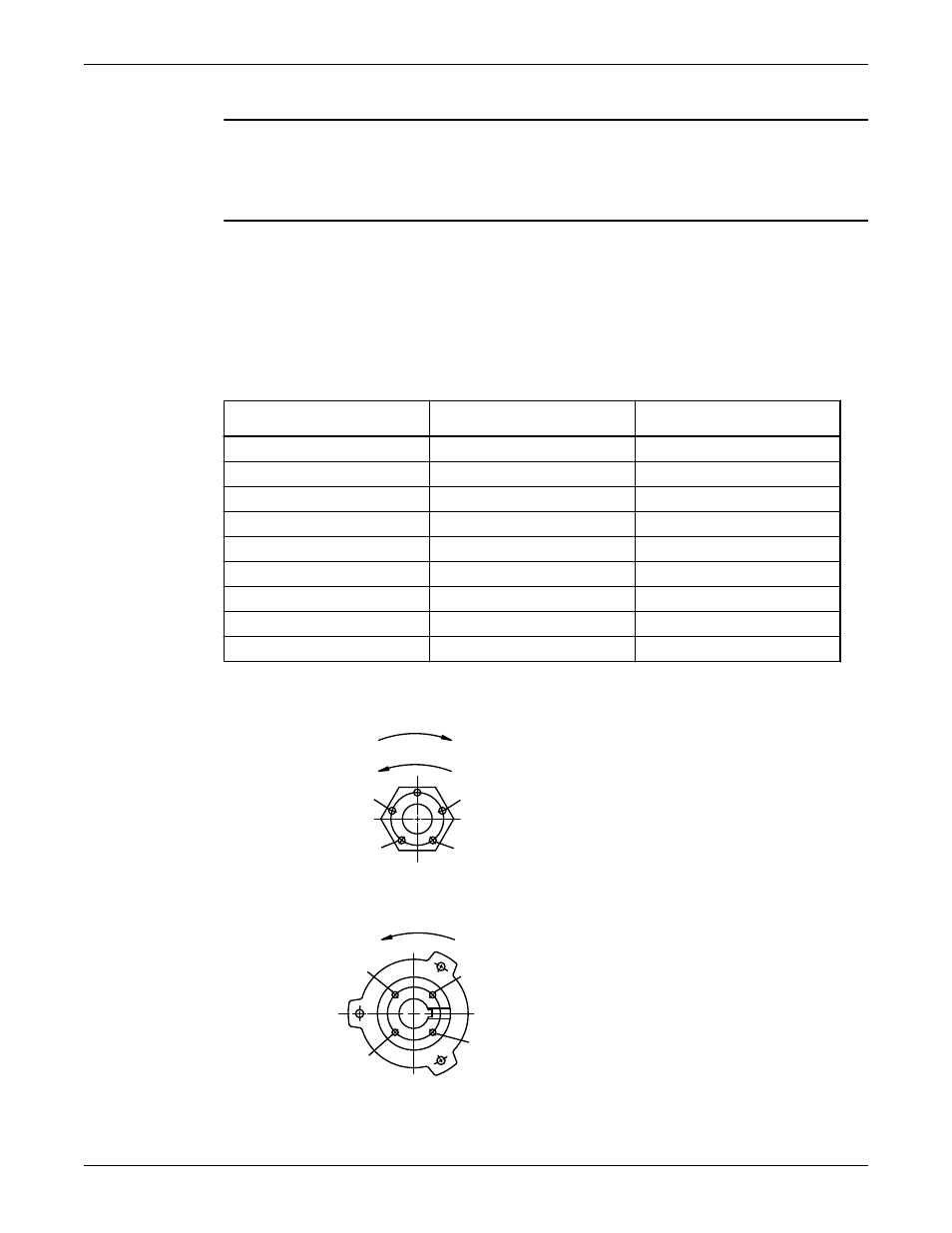

2. Turn the adjusting nut in a counterclockwise direction in order to lift the shaft until the impellers just

clear their seats and the shaft turns freely by hand.

This removes all deflection from the shaft.

3. Align hole A in the adjusting nut and hole C in the motor coupling.

If you are careful, you can reach an initial impeller clearance between 0.001 in. to 0.003 in. (0.02 mm

to 0.07 mm) depending on the shaft size and thread data shown in this table:

Shaft size

Thread

Vertical movement in 1/20th

turns - adjusting nut

¾ in. (19 mm)

¾-16 LH

0.003 in. (0.076 mm)

1 in. (25 mm)

1-12 LH

0.004 in. (0.10 mm)

1

3

/

16

in. (30 mm)

1-12 LH

0.005 in. (0.12 mm)

1½ in. (38 mm)

1-10 LH

0.005 in. (0.12 mm)

1

11

/

16

in. (42 mm)

1-10 LH

0.005 in. (0.12 mm)

1

15

/

16

in. (49 mm)

1-10 LH

0.005 in. (0.12 mm)

2

3

/

16

in. (55 mm)

1-10 LH

0.005 in. (0.12 mm)

2

7

/

16

in. (62 mm)

1-10 LH

0.005 in. (0.12 mm)

2

11

/

16

in. (68 mm)

1-8 LH

0.006 in. (0.15 mm)

AA

A

B

E

F

1

2

C

D

H

G

BB

3

1.

Lower impeller

2.

Raise impeller

3.

Correct impeller rotation

Installation (Continued)

Model VIC Installation, Operation, and Maintenance

43