Suction and discharge piping checklist, Install a partially-assembled pump – Goulds Pumps VIC - IOM User Manual

Page 20

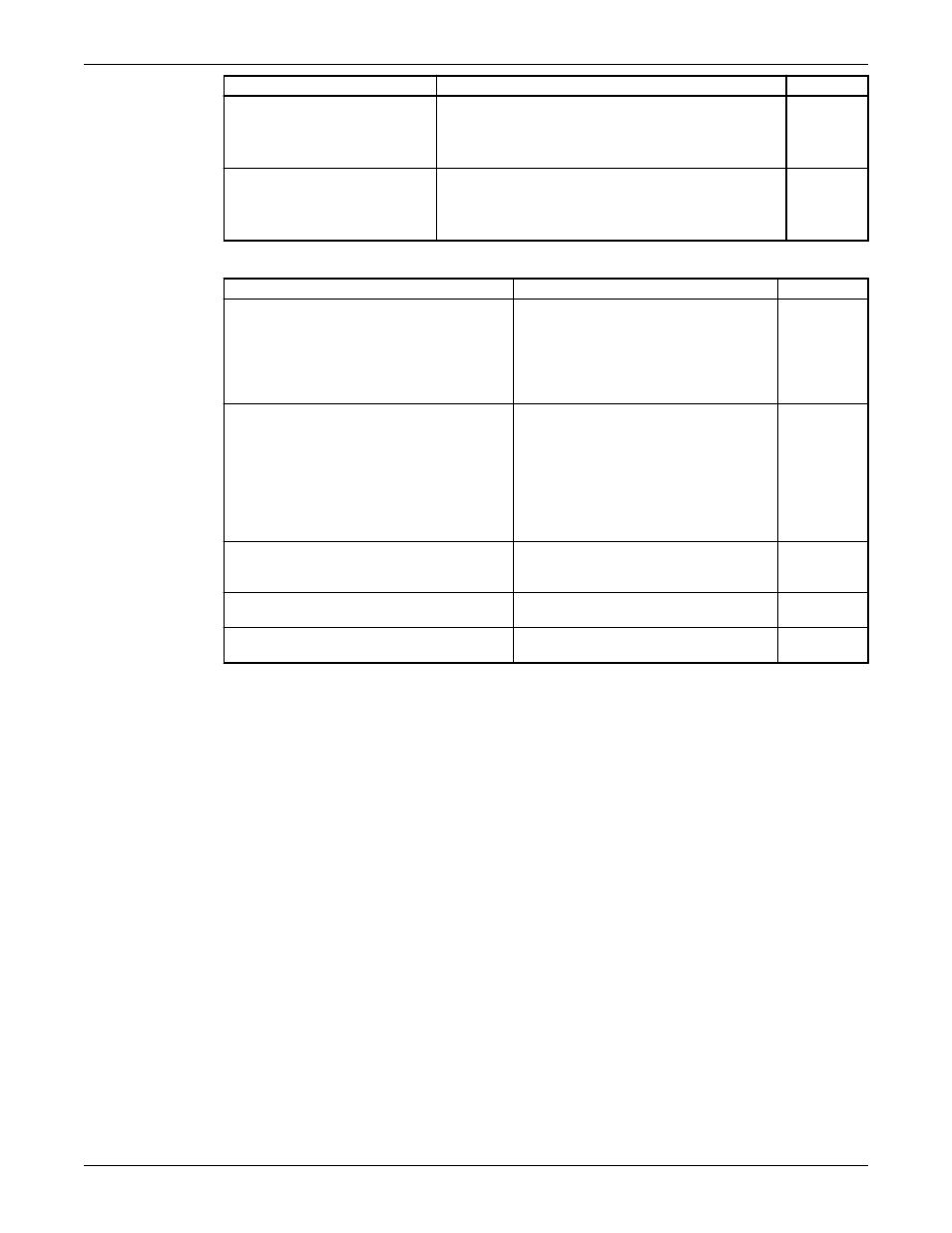

Check

Explanation/comment

Checked

If the pump handles liquids at

elevated temperatures, make sure

that the expansion loops and

joints are properly installed.

This helps to prevent misalignment due to thermal

expansion of the piping.

Make sure that all piping

components, valves and fittings,

and pump branches are clean

prior to assembly.

—

Suction and discharge piping checklist

Check

Explanation/comment

Checked

Check that isolation valves are installed in the

suction and discharge line.

Isolation valves are required for:

• Priming

• Regulation of flow

• Inspection and maintenance of the

pump

Check that check valves are installed in the

suction and discharge lines, between the

isolation valve and the pump discharge head.

The location between the isolation valve

and the pump allows inspection of the

check valve.

The check valve prevents damage to the

pump and seal due to the back flow

through the pump, when the drive unit is

shut off. It is also used to restrain the

liquid flow.

If increasers are used, check that they are

installed between the pump and the check

valve.

—

If quick-closing valves are installed in the

system, check that cushioning devices are used.

This protects the pump from surges and

water hammer.

If increasers are used, they must be of the

eccentric type.

This prevents air from collecting at the top

of the discharge pipe.

Install a partially-assembled pump

Pumps 20 feet (6 meters) or less in length are usually shipped partially assembled, with the exception of

these parts:

• Driver

• Packing

• Mechanical seal with piping

• Coupling assembly, spacer or non-spacer type

Refer to the Certified Pump Outline Drawing for the location of the anchor-bolt holes.

1. Clean the barrel flange and the bottom of the discharge head.

2. Check that all pump fasteners are tight since transportation and handling can result in bolt relaxation.

3. Install the barrel-to-discharge head O-ring.

4. Attach shackles to the discharge head lifting lugs or thread two eyebolts through the bolt holes in the

mounting flange.

5. Hoist the unit into position over the foundation.

Make sure that the shackles, eyebolts, and sling are rated to handle in excess of the pump weight. See

the outline drawing.

6. Carefully guide the unit so that it does not strike the sides of the sub-base or foundation.

7. Lower the unit until the discharge-head flange engages and rests firmly on the barrel flange, then

secure it with the capscrews provided.

8. When a lineshaft is shipped separately, complete these steps:

Installation (Continued)

18

Model VIC Installation, Operation, and Maintenance