Goulds Pumps VIC - IOM User Manual

Page 47

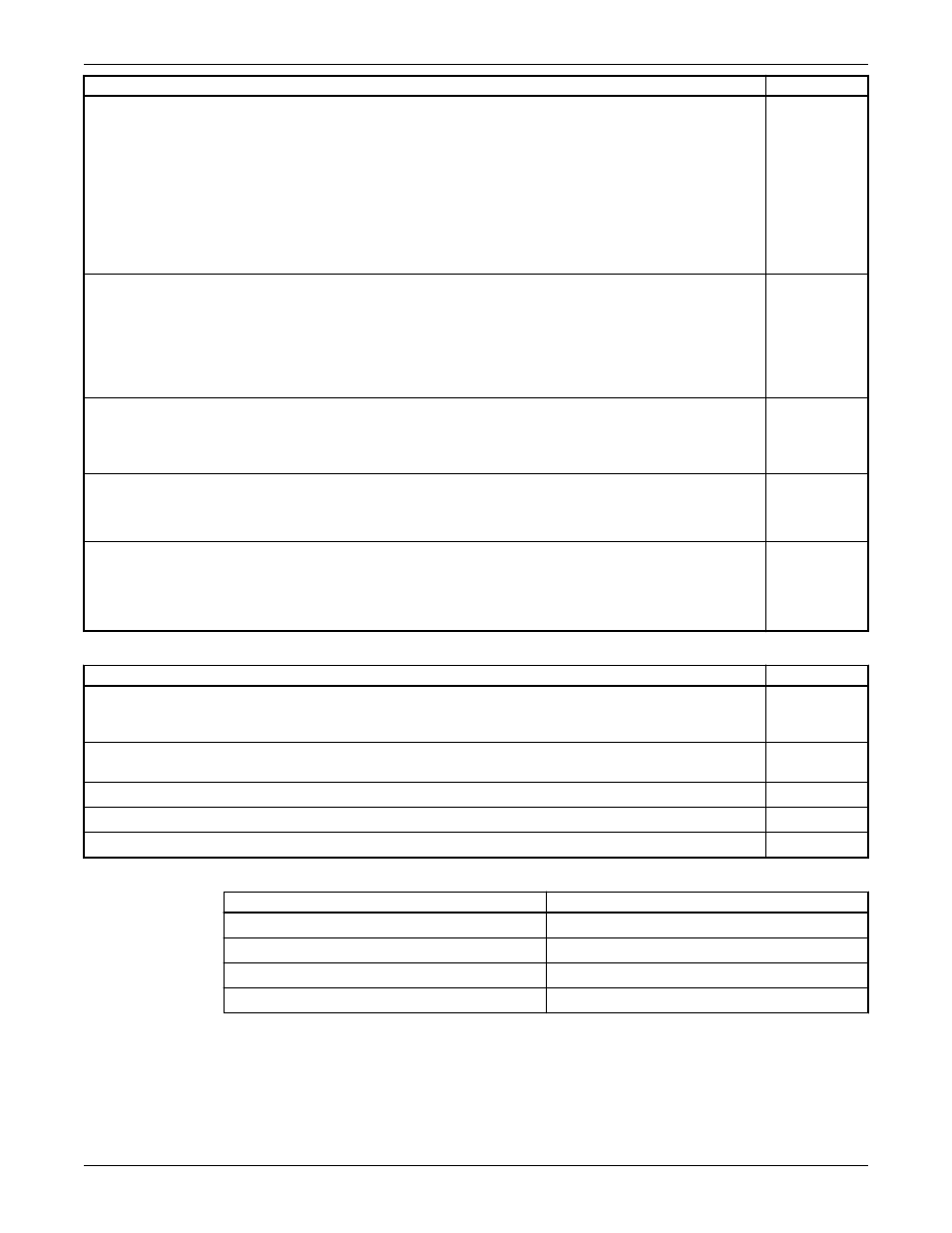

Check

Checked

Before you couple the driver to the pump, verify the proper rotation of the driver by bumping it. The proper

rotation for vertical pumps is counterclockwise when viewed from above.

Run the pump uncoupled in order to check that the driver runs smooth and sounds normal.

• For VHS motors, remove the driveshaft if a coupling is provided. If a coupling is not provided, then remove

the steady bushing and driver coupling.

• On drivers with NRRs. remove the rachet pins, if possible. Otherwise, rotate the drive coupling clockwise

until the pin stops tight against the rachet plate.

If a customer refuses to allow you to check the rotation, have the customer sign and date this checklist before

you proceed.

After you verify the proper rotation of the driver, you can couple the pump to the driver.

• On VSS units with a flanged coupling except for the AR type, set the impeller lift.

• On VHS units, set the impeller lift using the adjusting nut on top of the motor after you make up the

threaded or AR coupling.

See either the pump nameplate or the outline drawing for the specific impeller lift required for an individual

pump.

Check the alignment on pumps that are equipped with jacking bolts since they require that the motor be

physically aligned to the pump.

Special alignment of the pump to the motor is not usually required since all components are equipped with

register fits.

Use a dial indicator in order to check that the shaft runout above the sealing element is not excessive:

• Packing limit is a maximum of 0.008 in. (0.020 cm)

• Mechanical seal limit is a maximum of 0.005 in. (0.0123 cm) For API, the maximum is 0.002 in. (0.005 cm)

On units with seals, check these items:

• Check that the seal rotates freely.

• Check that the seal spacers are removed.

• Check that the seal piping is properly installed.

Part 3: Unit startup

Check

Complete

After you complete all of the checks in Parts 1 and 2, conduct a start-up meeting with customer in order to

discuss the actual procedures they might require during start-up and commissioning. Also, verify with the

customer that their system is ready for pumped fluid.

When the system is ready, push the start button and adjust the discharge valve in order to meet the design point,

if required.

Watch for signs of trouble. The unit must run at least ten minutes in order to flush out the pump and system.

Verify that the unit runs smoothly with no unusual noise, vibration, or over heating.

Run the unit for one hour in order to test the system.

Measurements

Reading

Value

Impeller lift

Shaft runout

Megger

Vibration

Installation (Continued)

Model VIC Installation, Operation, and Maintenance

45