Maintenance of bearings – Goulds Pumps AF (Axial Flow) (6"-36) MXR Bearings" User Manual

Page 40

38

AF (6-36) IOM

Check for unusual noise, vibration and bearing

temperatures.

Inspect pump and piping for leaks

Check seal chamber/stuffing box leakage

Packing: Excessive leakage requires adjustment

or possible packing replacement. Refer to page

35 for packing gland adjustment.

Mechanical Seal: Should be no leakage.

3 MONTH INSPECTIONS

Check foundation and hold down bolts for

tightness.

If pump has been idle, check packing. Replace if

necessary.

If any rubbing noise has been noticed, re-align the

impeller.

Oil should be changed at least every 3 months

(2000 hrs) or more often if there are any adverse

atmospheric conditions that might contaminate or

break down the oil, or if it is cloudy or

contaminated as seen through the sight glass.

ANNUAL INSPECTIONS

Check pump capacity, pressure and power. If

pump performance does not satisfy your process

requirements, and process requirements have not

changed, pump should be disassembled,

inspected, and worn parts should be replaced,

otherwise, a system inspection should be done.

MAINTENANCE OF BEARINGS

Operation of the unit without proper

lubrication will cause bearing failure,

and pump seizure.

Throughout this section on bearing

lubrication, different pumpage

temperatures are listed. If the

equipment is ATEX certified and the

listed temperature exceeds the

applicable value shown in Table 1

under ATEX identification, then that

temperature is not valid. Should this

situation occur, please consult with

your ITT/Goulds representative.

OIL LUBRICATED BEARINGS

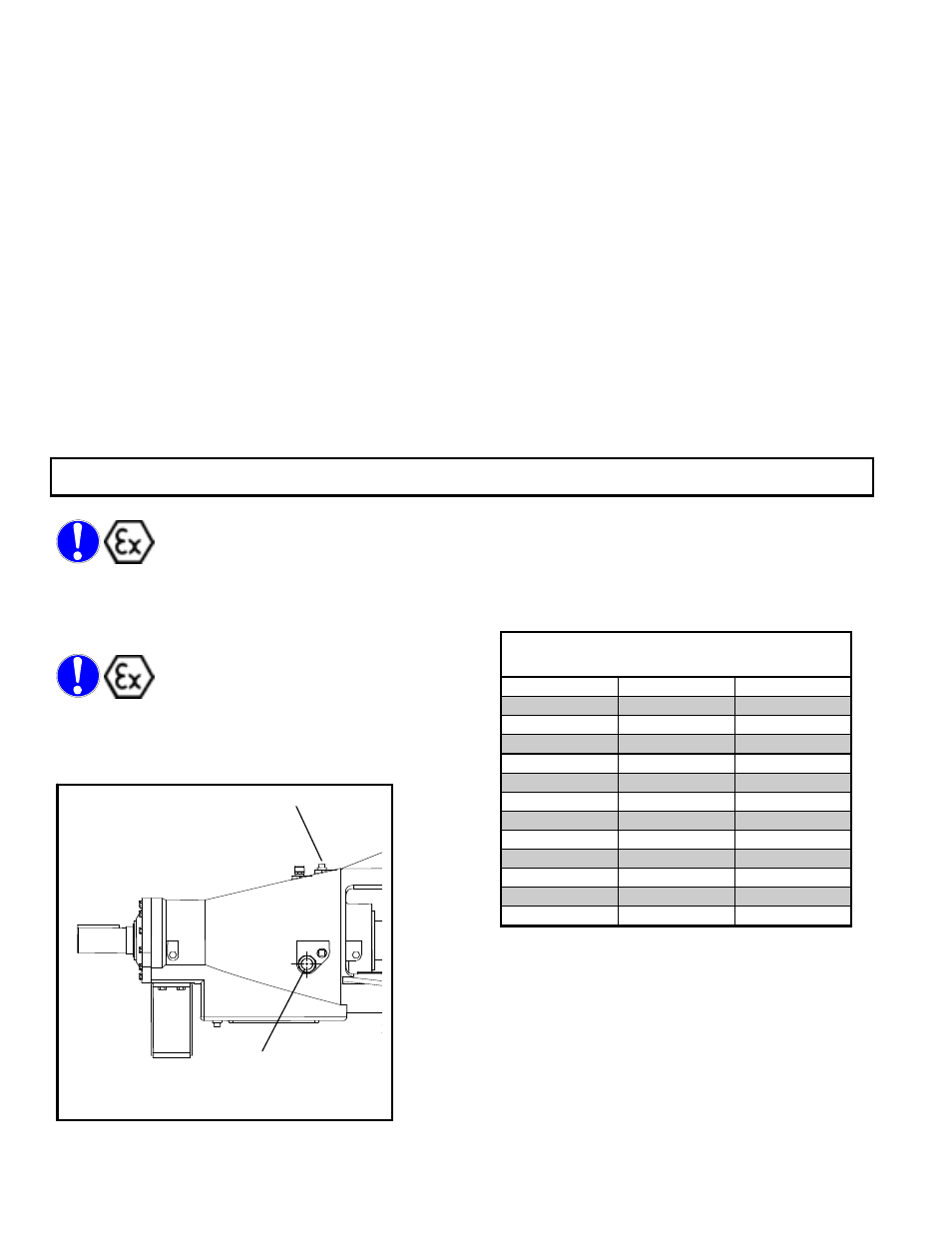

Remove the fill plug (408D) and add oil until oil level is

at the center of the sight glass (319). Replace the fill

plug, see Fig. 24 and Table 2.

Change the oil after 200 hours of new bearings,

thereafter every 2000 operating hours or 3 months

(whichever comes first).

Goulds recommends commercial oil such as

Mobil D.T.E.

Exxon Teresstic

AXIAL FLOW PUMP

OIL VOLUME

Pump Size

Quarts

Litres

6”

1

.95

8”

1

.95

10”

1

.95

12”

4

3.80

14”

4

3.80

16”

8

7.60

18”

8

7.60

20”

19

18.10

24”

19

18.10

700mm

19

18.10

30”

19

18.10

36”

29

27.55

Table 2

Fig 24

408D

319