Myron L 729II User Manual

Page 62

58

3. Slowly shake the sensor to remove air bubbles from

inside the sensor bore hole.

4. Allow 5-10 minutes for temperature to equilibrate. For

the quickest and the best results, both the sensor and

solution should be at the same temperature.

5. Turn power ON.

6. Read the display of the instrument. The display should

match the value and units of measure located on the

bottle of standard solution. If the reading is different,

adjust CALibration control on the main circuit board

until the reading matches the solution value. This will

require removal of the front panel. For removal, see

section V.C.1.a. 1-4.

7. After adjustment, turn power OFF.

8. Re-install front panel as described below in

“REASSEMBLY”.

9. To operate, turn power ON.

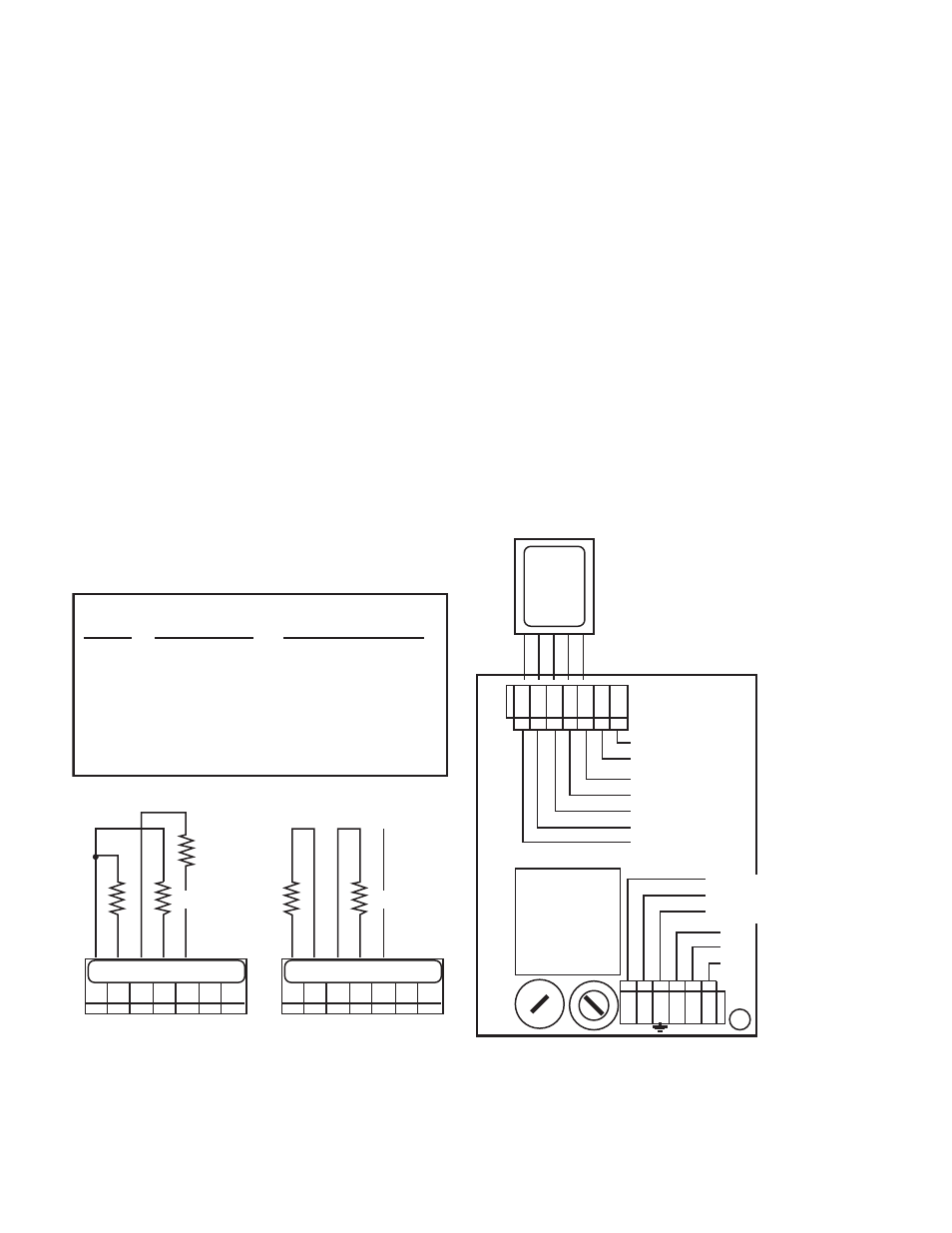

3. SENSOR SUBSTITUTE CALIBRATION

NIST traceable Sensor Substitutes are commonly use to verify

and calibrate Resistivity Monitor/controllers. Normally they are

not needed due to the “built-in “ electronic calibration or “Full

Scale Test”. However, your requirements may be such that a

crosscheck or verification is required. Sensor Substitutes are

available from the Myron L Company, see accompanying chart,

figure V.C.1, for part number.

If the proper Resistivity Sensor Substitute is not readily avail-

able and you can not wait for one to be delivered, one may be

constructed using the equivalent resister values listed on the

accompanying chart, figure V.C.1 and schematic, figure V.C.2.

NOTE: If you have previously performed a system calibra-

tion with either a NIST Standard Solution, or using the transfer

standard method, using this procedure will make that calibra-

tion invalid. You must decide which is more important, a system

calibration, or an electronic calibration.

1. Ensure power is OFF.

2. Using a standard slot screwdriver remove the four (4)

screws on the front panel.

3. Carefully wiggle the front panel to loosen and pull gently

toward you. Do not pull more than about 8 inches/

20CM or you could damage the wiring harness.

4. Turn the front panel around so that the back side is

facing you and set aside.

5. Locate and remove the sensor leads from the sensor

connector as shown in figure V.C.3.

6. Install Sensor Substitute with label toward transformer

as shown in figure V.C.3.

7. Turn power ON.

8. Display reading should be full scale of range. If not,

adjust CALibration control to read full scale, i.e. 0-500 KΩ

range should indicate 500, 0-10.00 MΩ = 10.00, and

0-20.00 MΩ = 20.00 at full scale. When setting digital

models with a full scale of 2000 (1999), it is advisable

to adjust Full Scale to 1990, otherwise an overrange

condition may occur.

9. After adjustment, turn power OFF.

10. Re-install front panel as described below in

“REASSEMBLY”.

11. To operate, turn power ON.

NC

CONDUCTIVITY/TDS

Figure V.C.2

5.49K 1%

X

RESISTIVITY

BK WT RD GN NU R- R+

BK WT RD GN NU R- R+

X

RESISTIVITY MONITOR/CONTROLLER

RANGE

PART NUMBER

RESISTER VALUE - X*

0-20 MΩ

0-10 MΩ

0-5 MΩ

0-2 MΩ

0-1 MΩ

0-500 KΩ

0-200 KΩ

CS-11

CS-12

CS-13

CS-14

CS-15

CS-16

CS-17

1 MΩ

500 KΩ

249 KΩ

100 KΩ

50 KΩ

24.9 KΩ

10 KΩ

*1%

Figure V.C.1

ALARM

CONTROL

RELAY

MAIN

INPUT

POWER

LINE-BLK/+DC

NEU-WHT/-DC

GND-GRN

}

}

Figure V.C.3

ELECTRICAL CONNECT DIAGRAM

CHASSIS GROUND for

OEM INSTALLATIONS ONLY

FUSE

115/230

SWITCH

L N

NC

NO

COM

0-10VDC

OUTPUT

NEU

GRN

RED

WHT

BLK

(+)

(-)

}

}

SENSOR SUBSTITUTE

LABEL TOWARD

TRANSFORMER

TRANSFORMER

CS-11

20 MEGΩ

RESISTIVITY

SENSOR

SUBSTITUTE

NIST TRACEABLE

INSTALL WITH

LABEL TOWARD

TRANSFORMER

MYRON L

COMPANY

5-01

100K 1%

10K 1%

SENSOR