Ii. installation, Double insulated – Myron L 729II User Manual

Page 13

A.

GENERAL

This section provides the recommended procedures for properly

installing the 750 Series II Conductivity/Resistivity Monitor/

controller, and sensors. For OEM models see section C.

WARNING: THE MYRON L COMPANY RECOMMENDS THAT

ALL MOUNTING AND ELECTRICAL INSTALLATIONS BE

PERFORMED BY QUALIFIED PERSONNEL ONLY. FAILURE

TO DO SO COULD CAUSE DAMAGE TO INSTRUMENT, AND

COULD BE HARMFUL OR FATAL TO PERSONNEL.

B.

MECHANICAL INSTALLATION

All Monitor electronics are packaged inside drip/weather-proof

housings. The physical dimensions of the housing is suitable for

panel, bench or surface mounting.

There are four basic guidelines to consider when selecting a

Monitor’s mounting location:

1. Select a site that limits the Monitor’s exposure to

excessive moisture and corrosive fumes.

2. For best results, position your Monitor/controller and

sensor as close as possible to the point(s) being

controlled. The 750 Series II Conductivity/TDS &

Resistivity Monitor/controllers are not designed to

operate with a Sensor cable length that exceeds 100 ft./

30 meters.

3. If at all possible, mount the Monitor at eye level for

viewing convenience.

4. If needed, the enclosure may be rotated or mounted

upside down so that the cutouts are on the opposite

side.

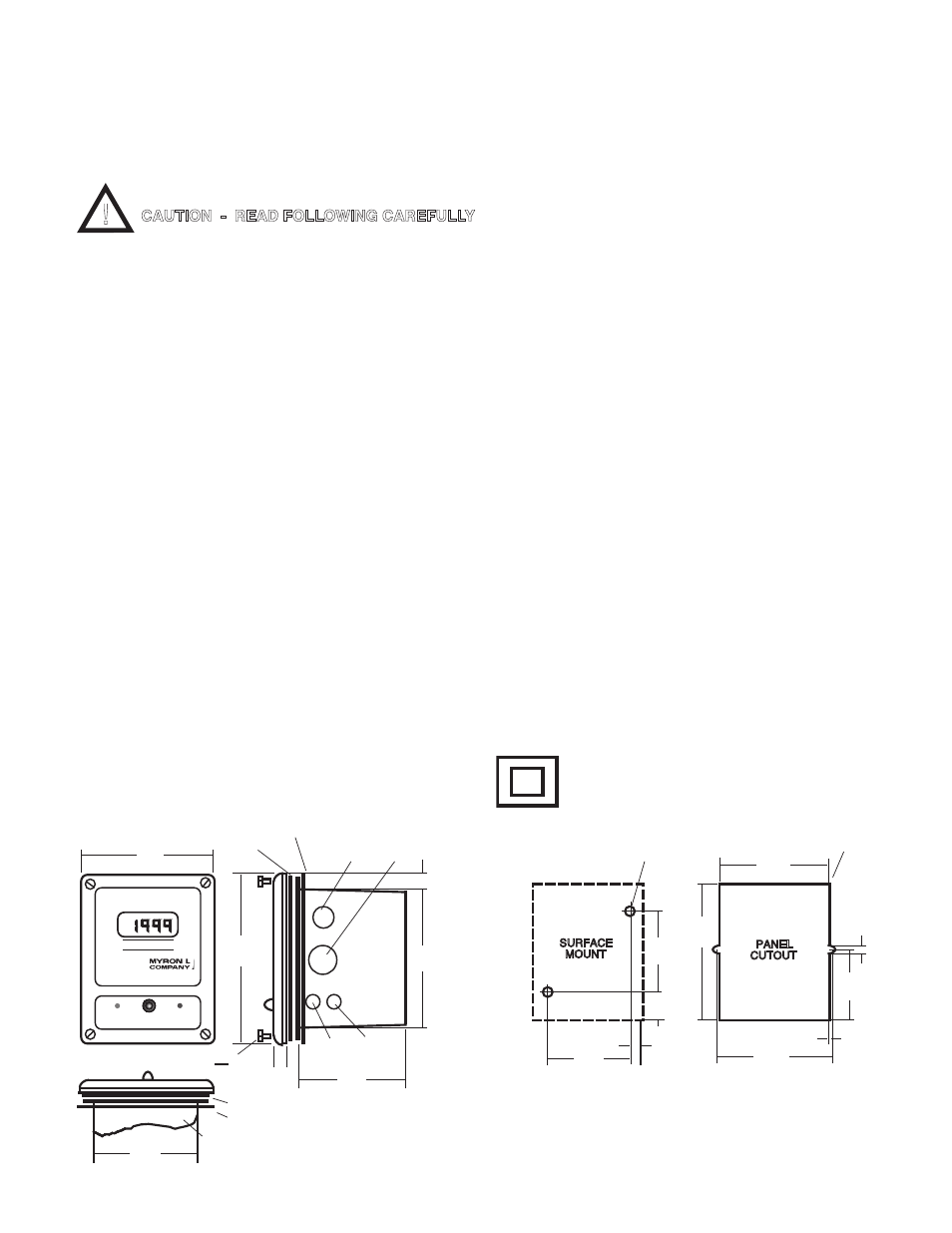

1. SURFACE MOUNTING WITH SMP

NOTE: A Surface Mounting Plate (SMP50) may be required

when access to the back side of the mounting site is impractical

or if the Monitor/controller must be mounted on a solid wall. The

SMP50 comes with the proper hardware to mount the Monitor/

controller to the SMP, however, the installer must provide the

four (4) additional screws/bolts to mount the SMP to the wall or

fixture. Their size is to be determined by the user.

1. Select your mounting location. Mark and drill the four

(4) required mounting holes. For hole locations, use the

SMP as a template.

2. Drill the corner holes in the SMP according to the size

of the screws or bolts selected.

3. Attach and securely fasten the SMP to the Monitor

using the 1/4” X 20 X 3/8” screws provided.

4. Mount the SMP to the prepared site using the selected

screws or bolts.

2. SURFACE MOUNTING WITHOUT SMP

NOTE: Surface mounting will require two (2) 1/4 “ X 20 screws

of a length equal to the thickness of the mounting site plus 3/8”

1. Select mounting site location. Mark and drill the

required mounting holes. For hole drilling locations, see

figure II.B.1.

2. Insert the 1/4” X 20 screws into the holes from the side

opposite the mounting site.

3. Hold the Monitor in place while starting and tightening

the mounting screws.

3. PANEL MOUNTING

A panel mounting fastening kit is provided with all Monitor/

controllers. Panel mounting will require the use of the fastening

kit’s two (2) 4-40 mounting screws/nuts or two (2) #4 x 1/2”

sheet metal screws. See figure II.B.1. for panel cutout

dimensions.

1. Select your mounting location. Mark the appropriate

panel cutout and complete the necessary panel cut.

2. Carefully unfasten and separate the Monitor’s front

panel from its enclosure.

3. Disconnect all panel cable(s)/wire(s) from the Monitor’s

Control board.

NOT TO SCALE

DIMENSIONS IN INCHES

(MILLIMETERS)

3.10

(79)

0.40

(10)

SURFACE

MOUNT

1.05

(27)

2.84

(72)

0.31 DIA, X2

(8)

5.00

(127)

3.96

(101)

0.13 RAD MAX, X

(3)

4

0.113

(3)

2.54

(64)

4.17

(106)

0.11

(3)

PANEL

CUTOUT

HIGH

LOW

SET POINT

4.80

(122)

3.89

(99)

(16)

6.00

(152)

0.5

(13)

0.88 DIA

(22)

1.13 DIA

(29)

0.53

(14)

4.94

(126)

0.60 DIA

(15)

3.78

(96)

0.50 DIA

(13)

750

MICROSIEMENS / CM

II

6-32x3/8" x4

Face Plate Gasket

Face Plate Gasket

Panel Gasket

Panel Gasket

0.63 THK

II. INSTALLATION

9

SURFACE AND PANEL MOUNTING DIAGRAMS

Figure II.B.1

!

CAUTION - READ FOLLOWING CAREFULLY

DOUBLE INSULATED