Myron L 729II User Manual

Page 20

16

G. RE-RANGE YOUR MONITOR/CONTROLLER

(Range Module Installation)

1. DESCRIPTION

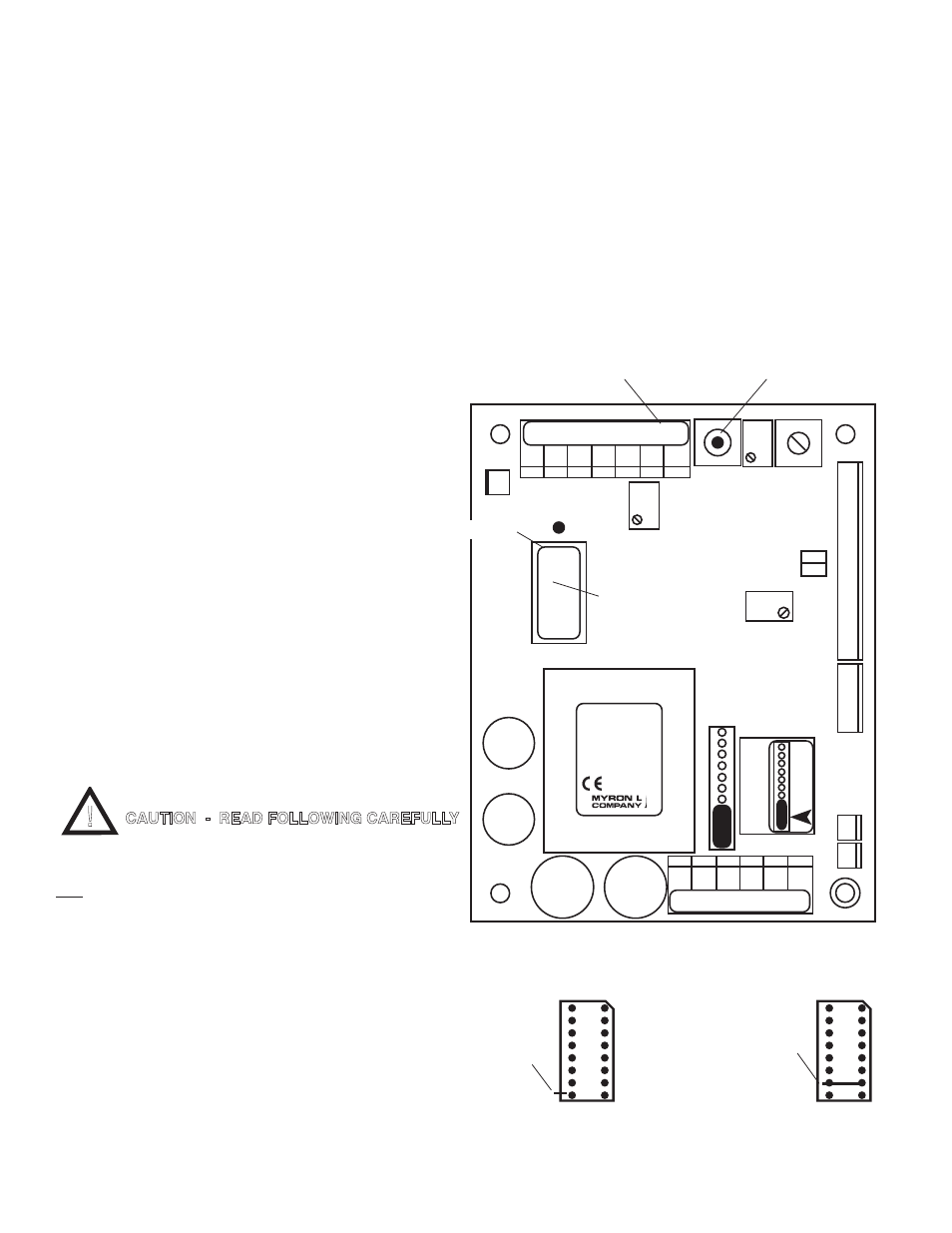

The 750 Series II Monitor/controllers have been designed for

easy field re-rangeability. The Range Module consists of a 16

pin Header that plugs into a 16 pin socket.

For available ranges, see Range Selection Guide I.G. When

making large range changes, i.e. 5000 ppm to 50 ppt, a different

sensor may also be required as noted in the Range Selection

Guide. Order Range Module by adding the prefix “RM” to the

range number as in examples below.

Conductivity/TDS Range Modules —

RMXXX

i.e. = RM121

is a 0-2000µS

Resistivity Range Modules

—

RMXX

i.e. = RM11

is a 0-20MΩ

NOTE: Some OEM models may not be re-ranged being

originally manufactured with a fixed range. If your application

requires re-ranging an OEM model, first contact the system

manufacture for help. The Myron L Company may re-range or

exchange your instrument at a cost.

2. INSTALLATION

Briefly -

The new Range Module simply replaces the Range Module

presently installed, see figure II.G.1.

Multiplier label is added to analog models*.

Type label may be required if changing from Microsiemens to

Millisiemens or PPM/PPT.

The Full Scale reading is recalibrated.

IMPORTANT NOTES:

1. When changing ranges on Digital Monitor/ controllers

with the -45 option (4 1/2 digit backlit display), the following

modifications may be required to the range module; RM123

thru 128 and RM16 require pin number 9 be removed or

bent toward the side, see Fig. II.G.2. On RM117 thru 122 a

jumper wire must be soldered to the RM, see Fig. II.G.3.

*2. Analog Monitor/controllers may require a scale change.

See section II.G.3 for the specific instructions.

WARNING: BEFORE STARTING, IF MONITOR/

CONTROLLER IS INSTALLED, ENSURE THE POWER IS

OFF. FAILURE TO DO SO COULD CAUSE DAMAGE TO

THE INSTRUMENT, AND COULD BE HARMFUL OR FATAL

TO PERSONNEL. ONLY QUALIFIED PERSONNEL SHOULD

INSTALL OR SERVICE ELECTRICAL EQUIPMENT.

Physical

NOTE: When opening instrument, remove front cover with care;

a ribbon cable connects the front panel and main board. If the

front panel has already been removed from the enclosure skip

to #4.

1. Using a standard slot screwdriver remove the four (4)

screws on the front panel.

2. Carefully wiggle the front panel to loosen and pull

gently toward you. Do not pull more than about

8 inches/20CM or you could damage the wiring

harness.

3. Turn the front panel around so that the back side is

facing you and set aside.

4. Locate and remove existing Range Module from MAIN

Circuit Board, as shown in figure II.G.1. It is not easy

to remove, it was designed to stay in place under

adverse conditions.

5. With the pointer up, carefully align the new Range

Module to the socket on the MAIN Circuit Board as

shown in figure II.G.1.

6. Press firmly into place.

7. For analog models, add multiplier label to front panel.

See figures II.G.10 and II.G.11 for suggested locations.

In some cases changing the meter scale will be

necessary. See Changing Analog Meter Scale, section

II.G.3.

8. Recalibrate, see CALIBRATION PROCEDURES,

section V.C.

BK WT RD GN NU R- R+

CHS

GND

UP

}

HYS1

SP1

FUSE*

115/

230

PWR C GD NC NO CM

DIS

CAL

3S

PA

RA

INC

DEC

SPC

TRANSFORMER

RANGE

MODULE

751 756

752 757

753 758

754 759

FS SW

FULL SCALE

PUSH TO TEST

0-10VDC

OUTPUT

-121

2000µS

POINTER

REMOVE T

O INST

ALL

SECOND RELA

Y

Main CB Assembly

Figure II.G.1

REMOVE

PIN #9

UP

DIGITAL 4 1/2 DIGIT LCD

MONITOR/CONTROLLERS ONLY

ADD JUMPER

CONNECTING

PINS 7 & 10

UP

RANGE MODULE

Bottom View

FIGURE II.G.2

FIGURE II.G.3

!

CAUTION - READ FOLLOWING CAREFULLY