Dow FROTH-PAK Refill Systems User Manual

Page 30

dow Building Solutions

Section 12

Ratios and Output

*Using cone type nozzle with chemicals at 75°F (24°C). Do not increase pressure over

225psi. PRV set @ 250psi.

nOTe: Checking the system output and chemical ratio can determine whether the

system is in good operating condition. A system blockage for example, is indicated

by an abnormally low output. Checking the ratio can indicate whether the problem is

related to the “A” or “B” side. The ratios and outputs for other products are similar to the

results listed above. However, temperatures lower than 65°F (18

°

C) or a faulty pressure

gauge on the nitrogen regulator assembly may cause substantial deviation.

Section 13

Anti-crossover Nozzles

The Dow Chemical Company provides various anti-crossover nozzles

with various spray patterns for use with the InSTa-FlO™ Gun . For best

results, operate the InSTa-FlO Gun between 6 and 36 inches from

the surface being sprayed . Move the InSTa-FlO Gun in a steady but

relatively slow back and forth motion . This will provide an even coverage .

Do not spray over rising foam .

The cone type nozzle provides a round spray pattern for multiple

applications and surfaces .

The fan type nozzle provides a fine fan spray pattern resulting in a

smooth foam surface (paint spray finish) .

The caulking type nozzle provides a bead pattern for ultra fine coverage

and has less overspray .

Refer to InSTa-FlO Gun and anti-Crossover nozzle drawings, pages a3-a4 .

Section 14

Nitrogen Regulator

14 .1 Important - Safety Information

1 .

neVeR use regulators on cylinders of which the gas

pressure exceeds 3000 pounds per square inch

2 . nEVER set chemical tank pressure over 225psi .

3 . nEVER use oil or petroleum base grease on regulator,

inlet connection, or cylinder valve . an explosion or

fire could result . The lubricant used on this regulator

adjusting screw is Dow-Corning no . 44 silicone grease

which is a non-petroleum base grease .

4 . nEVER stand in front of, or behind a regulator while

opening the cylinder valve .

14 .1 .1 Instructions

1 . Before attaching the regulator to the nitrogen cylinder valve

outlet, open the valve for a few seconds, allowing the

gas to force out any possible foreign matter .

2 . attach the regulator to the nitrogen cylinder valve and

tighten the inlet nut securely with an adjustable wrench .

3 . Before opening the cylinder valve, turn the adjusting

screws (valve stems) to the left until no tension is felt .

nOTe: NEVER open cylinder valve until spring tension on the valve

stems have been released.

4 . Open cylinder valve slowly . DO nOT stand in front of

or behind regulator while opening the cylinder valve .

5 . Turn valve stems clockwise until the low pressure gauge

registers the desired working pressure .nitrogen Regulators

are available through The Dow Chemical Company or:

airgas north Central Inc .

1250 W . Washington Street

West Chicago, Il 60185

Phone: (630) 231-9260

Refer to nitrogen Regulator assembly drawing, page a-2 . The regulator is not pressure

releasing - turning the regulator to a lower psi will not reduce pressure in the tank until the

pressure is manually vented .

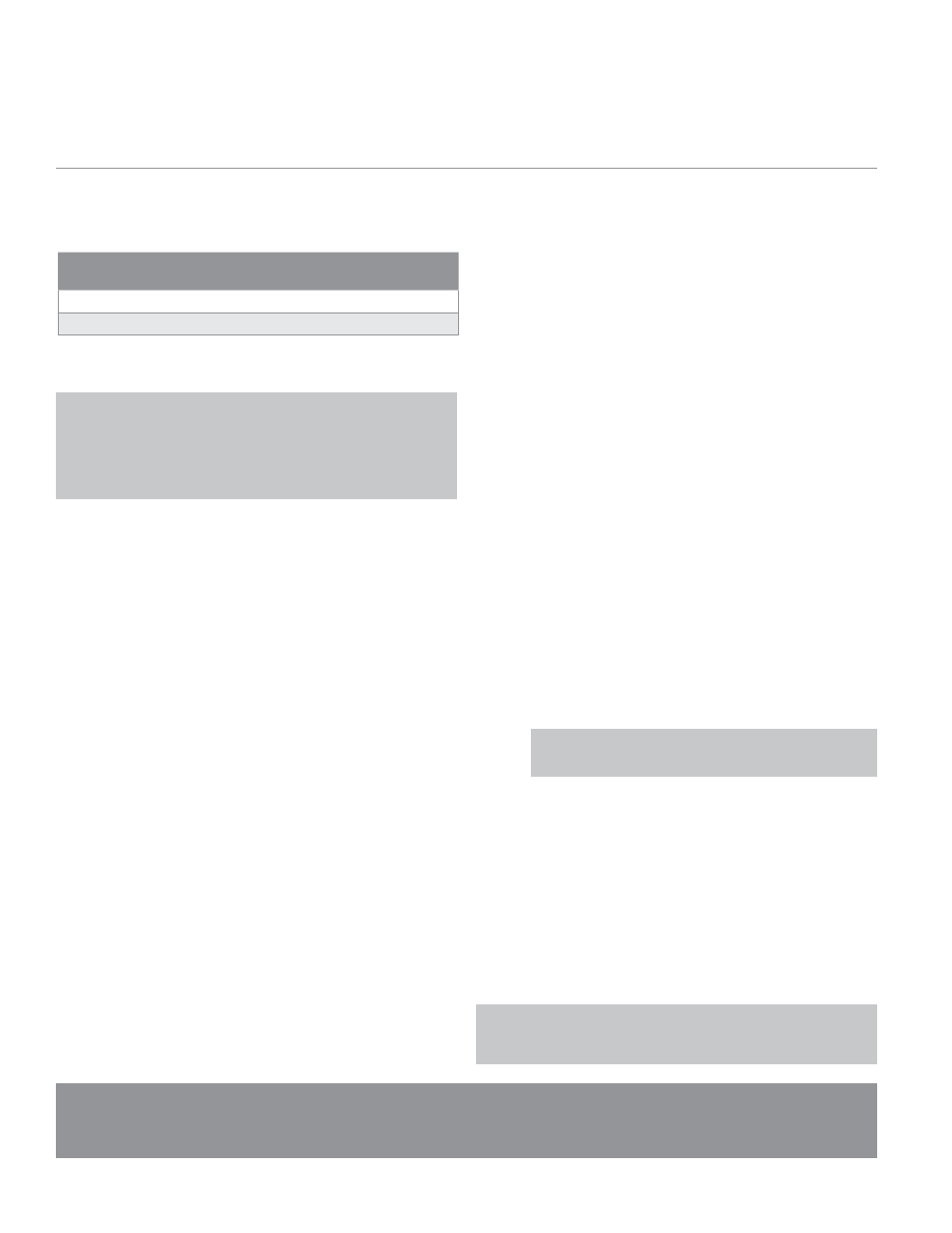

density

PSi (A / B)

nominal

Output*

nominal Ratio

(A : B)

1.75

120 / 120

3.6 lbs/min

1.0 : 1.0

1.75

140 / 140

4.0 lbs/min

1.0 : 1.0

22