Dow THERMAX™ Wall System User Manual

Installation procedures for thermax, Wall system, Continuous insulation/ drainage plane

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

I N S T A L L A T I O N

I N F O R M A T I O N

.

C O M M E R C I A L

(CM Series) contractor foams a

similar portion of the wall on the

interior side.

This system of products provides

scheduling overlaps that can save

significant time on a project,

minimizing negative impacts and

providing an opportunity for multiple

contractors to engage in finishing the

exterior wall throughout the project.

CONTINUOUS INSULATION/

DRAINAGE PLANE

INSTALLATION RECOMMENDATIONS

1. With printed side facing to the

exterior, install THERMAX

™

(ci)

Exterior Insulation horizontally

with the shiplap edge up (for

boards that contact the steel studs).

2. Use maximum board lengths to

minimize number of joints. Locate

edge joints parallel to and on

framing flange. Center end joints

over supports and stagger in each

course.

3. Anchor to exterior face of exterior

metal stud wall framing with

appropriate fastener. Abut

insulation boards tightly together

around openings and penetrations.

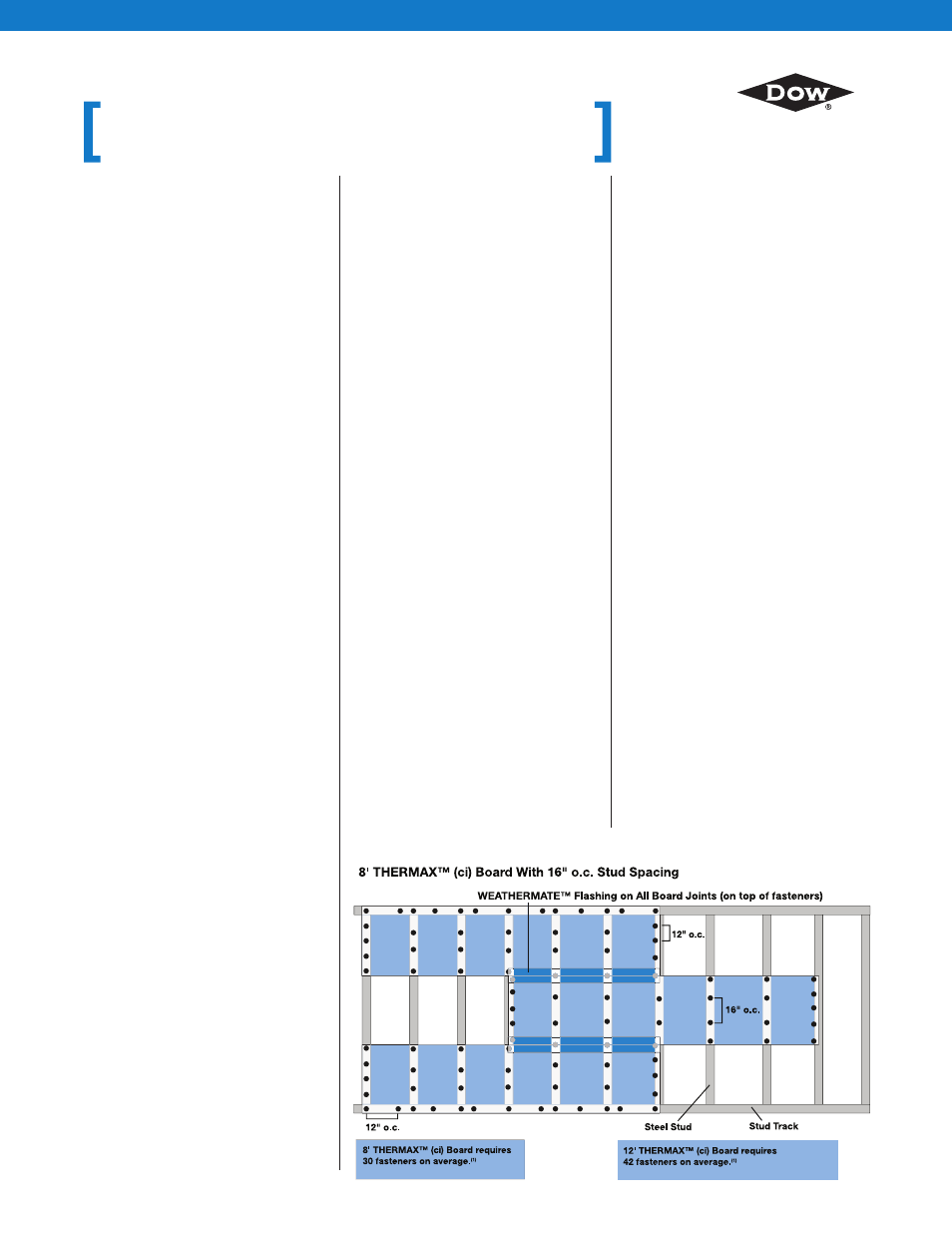

4. Fasten boards of THERMAX

™

(ci)

Exterior Insulation to each

support with fasteners spaced

12" o.c. at perimeter and 16" o.c.

in the field. Dow has specified the

Wind-Lock ci-LOCK fastener/

washer because it was used for

the ASTM E330 wind load testing.

Other fasteners designed

specifically for rigid foam

sheathing may be used, including

those listed on page 19 of Tech

Solutions 513.0: THERMAX

™

Wall

System, which is available at

www.thermaxwallsystem.com.

See Figure 1 for recommended

fastening pattern. Set back

perimeter fasteners 3/8" from

board edges and ends. One

approved fastener/washer can be

placed to bridge a maximum of

two board edges. Drive fasteners

to bear washer tight and flush

with surface of insulated

sheathing. Do not countersink.

5. For optimum performance and to

create a water-resistive barrier,

seal all end and edge joints, and

thru-wall penetrations, such as

window and door openings, with

WEATHERMATE

™

Flashing.

6. It is critical that flashing be

attached in shingle fashion on the

face of THERMAX

™

(ci) Exterior

Insulation and that all thru-wall

penetrations are properly flashed

to achieve a continuous drainage

plane. A minimum overlap the

width of the flashing is

recommended. For example, if

using 4" wide WEATHERMATE

™

Flashing, overlap by at least 4".

7. THERMAX

™

(ci) Exterior Insulation

boards should be properly repaired

if damaged during installation.

Repairs may include applying a

strip of flashing over a small hole

or filling a large hole with a piece

Installation Procedures for

THERMAX

™

Wall System

SEQUENCING OVERVIEW

Installation of the THERMAX

™

Wall

System can begin once the structural

steel and exterior wall steel studs

have been installed and braced.

By using the all-steel bracing design,

a drywall or masonry contractor can

begin immediately installing boards

of THERMAX

™

(ci) Exterior Insulation

on the exterior of the building envelope.

(Insulation can be left exposed for

180 days.) As the contractor applies

succeeding boards, WEATHERMATE

™

Flashing is adhered to adjoining

board joints and at pre-determined

thru-wall penetrations. Windows and

other openings are flashed following

the removal of excess THERMAX

™

(ci)

Exterior Insulation in these areas of

the envelope.

With the building closed in, the

structure has an insulated and

weatherized envelope, which will

allow for work to progress quickly

on the interior of the structure. By

completing this step, a building can

begin to be conditioned, which can

speed up the work of other trades

beyond the exterior walls.

Once sections of insulation boards

and flashing are in place, a contractor

can follow this work and adhere a strip

of flashing to the face of the insulation

(where the tie will be inserted). Veneer

ties used to anchor the final exterior

of the building can then be mounted.

When the necessary ties are in place,

masonry work or installation of other

veneers can begin on these areas of

the building.

After the ties are secured to the

steel studs on the interior, it is

important to ensure that, if necessary,

a floor line fire-stop is installed in

the stud cavity. STYROFOAM™

brand Spray Polyurethane Foam

Insulation (CM Series) can now be

applied in the stud cavity, covering

the fire-stop (if installed) back to the

floor edge to complete the air barrier,

to further seal and insulate the

envelope. STYROFOAM™ brand

Spray Polyurethane Foam

Insulation (CM Series) should be

applied after the chosen veneer ties

are in place. This allows free access

for proper attachment of the tie.

However, once the ties are in place,

bricks can be laid on the exterior

while a STYROFOAM™ brand

Spray Polyurethane Foam Insulation

Figure 1: Fastening Pattern for THERMAX

™

(ci) Exterior Insulation

(1) Average number stated may be less when washers are used to bridge adjoining boards or more when a true fastening perimeter outlines all four edges of the board.