Pulleys and belts, Replacing pulleys and belts – COOK VCR User Manual

Page 5

5

Maximum RPM

Replacing Pulleys and Belts

a. Clean the motor and fan shafts.

b. Loosen the motor plate mounting bolts to relieve the

belt tension. Remove the belt.

c. Loosen the pulley setscrews and remove the pulleys

from the shaft.

If excessive force is required to remove the pulleys, a

three-jaw puller can be used. This tool, however, can

easily warp a pulley. If the puller is used, inspect the

trueness of the pulley after it is removed from the

shaft. The pulley will need replacement if it is more

than 0.020 inch out of true.

d. Clean the bores of the pulleys and place a light coat of

oil on the bores.

e. Remove grease, rust and burrs from the pulleys.

f. Place fan pulley on the fan shaft and the motor pulley

on the motor shaft. Damage to the pulleys can occur

when excessive force is used in placing the pulleys on

their respective shafts.

g. After the pulleys have been correctly placed back onto

their shafts, tighten the pulley setscrews.

Belt and Pulley Installation

Belt tension is determined by

the sound of the belts when the

fan is first started. The belts

will produce a loud squeal,

which dissipates after the

fan is operating at full

capacity. If belt tension is

too tight or too loose,

lost efficiency and

damage can occur.

Do not change the

pulley pitch diameter

to change tension. The

change will result in a different

fan speed.

a. Loosen motor plate adjustment bolts

and move motor plate so that the belts easily slip into

the grooves on the pulleys. Never pry, roll, or force the

belts over the rim of the pulley.

b. Slide the motor plate back until proper tension is

Size

VCR

VCR-HP

VCR-XP

Standard

Reinforced

Standard

Reinforced

100

2002

-

120

1671

-

135

1574

-

150

1520

-

1952

-

165

1295

-

1728

-

2508

180

1546

-

1829

-

2396

195

1353

-

1570

-

2100

210

1227

-

1626

-

2126

225

1086

-

1435

-

1879

245

901

-

1185

1234

1616

270

766

-

1025

1049

1656

300

837

877

980

1046

1391

330

716

748

830

912

1182

365

624

659

735

872

1132

402

539

560

-

445

463

473

490

360

403

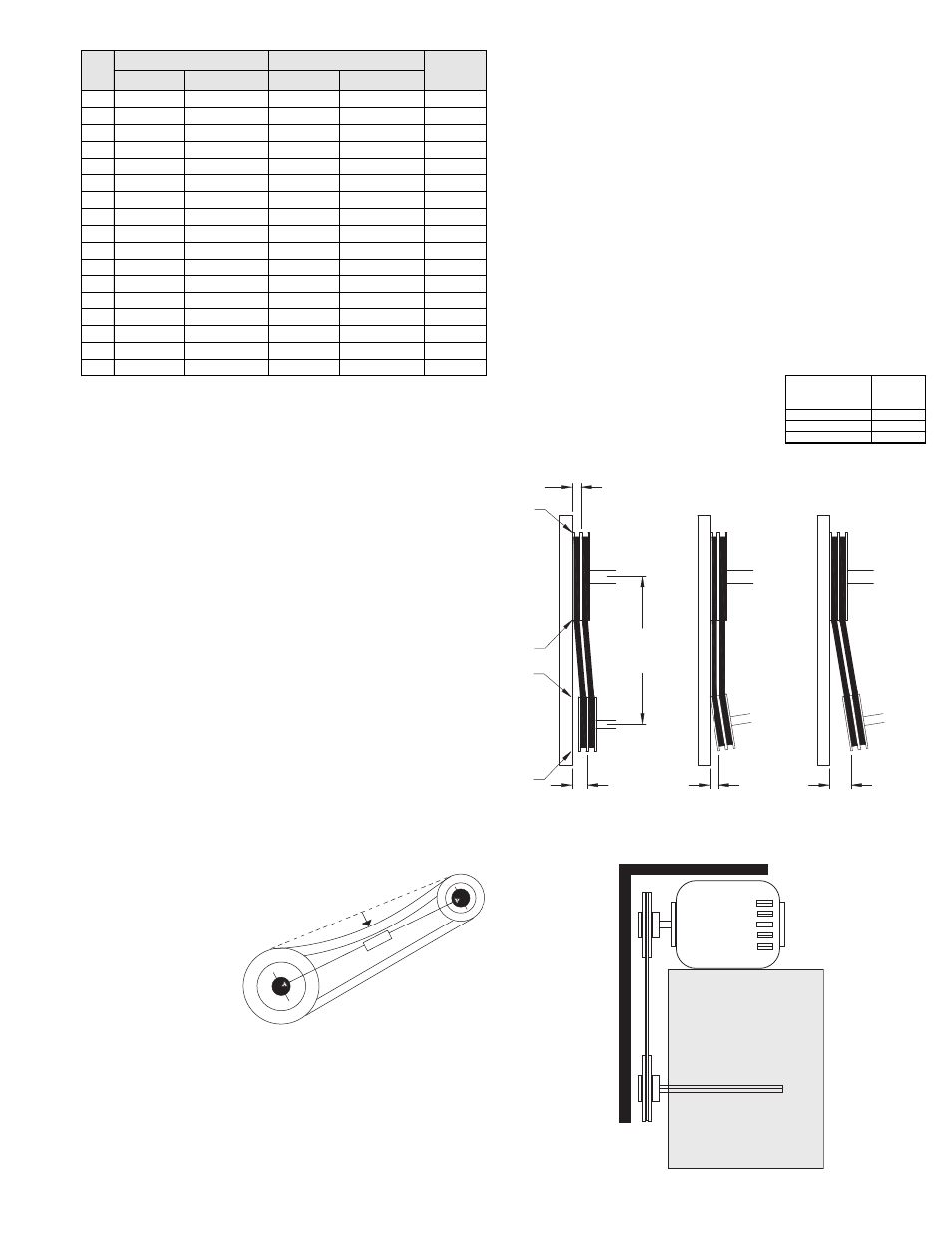

OFFSET

ANGULAR

OFFSET/ANGULAR

A

W

X

Y

Z

B

CENTER

DISTANCE

(CD)

GAP

GAP

reached. For proper tension, a deflection of approxi-

mately 1/4” per foot of center distance should be

obtained by firmly pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment bolts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pul-

ley setscrew and by moving the motor pulley on the motor

shaft.

Figure 2 indicates where to measure the allowable gap

for the drive alignment tolerance. All contact points (indi-

cated by WXYZ) are to have a gap less than the tolerance

shown in the table. When the pulleys are not the same

width, the allowable gap must be adjusted by half of the dif-

ference in width. Figure 3 illustrates using a carpenter’s

square to adjust the position of the motor pulley until the

belt is parallel to the longer leg of the square.

Figure 2

1 foot

1/4 inch

Figure 1

Center Distance

Maximum

Gap

Up thru 12”

1/16”

12” up through 48

1/8”

Over 48”

1/4”

Figure 3