Wiring, Wiring installation, Typical damper motor schematic – COOK VCR User Manual

Page 2: Vcrd with shade pole or psc motors

2

b. Minimum exhaust velocity in the duct should be 1500

FPM in accordance with NFPA 96.

c. If the fan is installed on a surface that is not level, install

the fan in a position that places the drain tube at the

lowest position.

d. Secure the fan to the roof curb at all four corners using

a minimum of four anchor bolts, lag screws or other

suitable fastener.

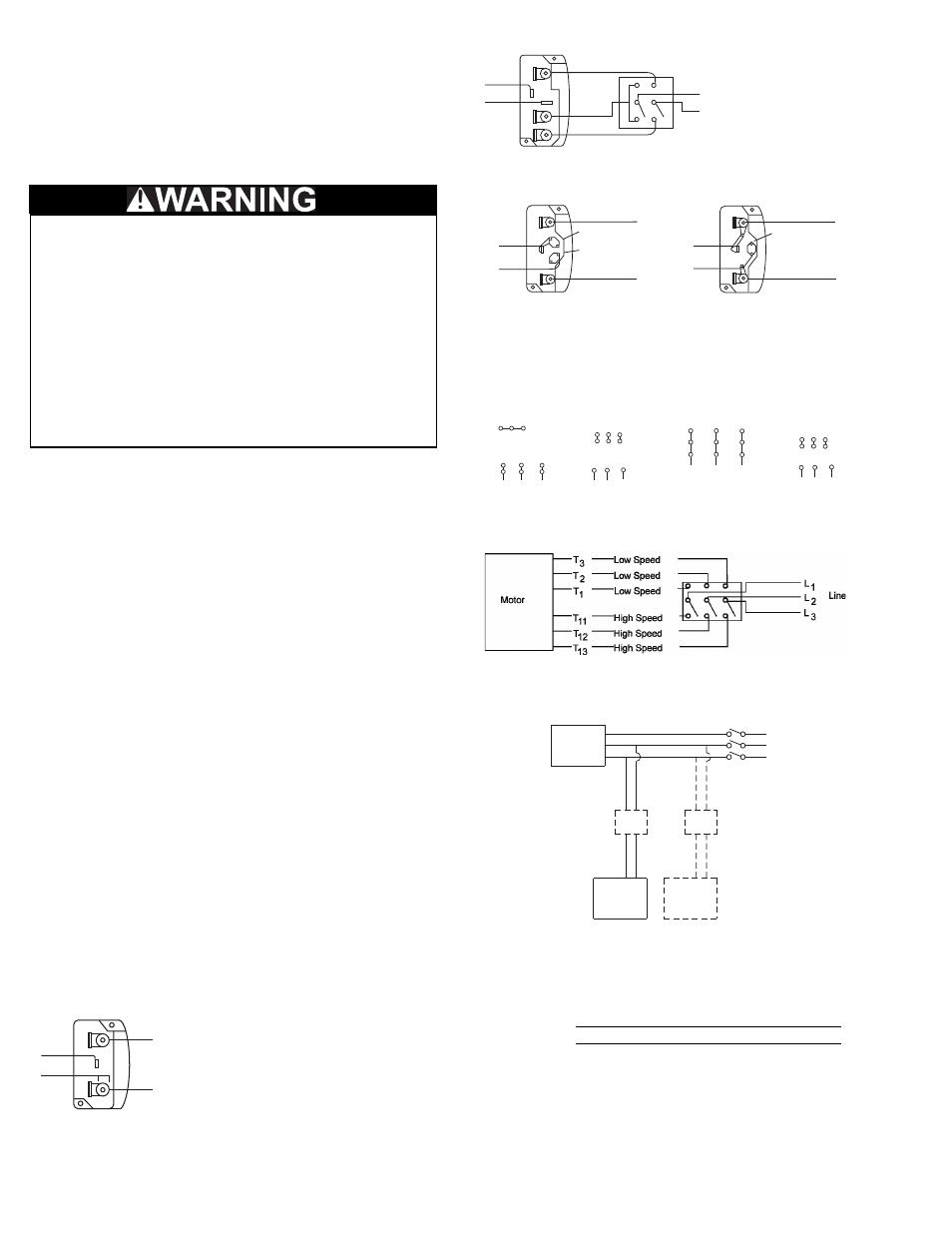

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate. Refer to the following Wiring Diagrams.

Upblast units have two wiring conduits. The vertical con-

duit comes plugged. The horizontal conduit is directly above

vertical conduit.

Lock off all power sources before the fan is wired to power

source.

NOTICE! Follow the wiring diagram in the disconnect

switch and the wiring diagram provided with the motor.

Correctly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Fan With a Junction Box

a. Wire the motor using the junction box located on the

outside of the fan.

b. Reinstall the junction box cover and ensure that the

gasket forms a complete seal.

Fan Without a Junction Box

A field wiring compartment must be installed for wire con-

nections. Wire the motor by pulling the electrical wire

through the conduit. For further information refer to the

National Electrical Code and the wiring diagram provided on

the motor.

Single Speed, Single Phase Motor

All wires must be protected from abrasion when

passing through the opening of a field wiring

compartment.

Do not use cooling tubes for electrical connections.

Do not use vertical conduit if fan will be used in a

grease and/or heat exhaust application, use of the

vertical conduit does not conform to NFPA 96 and UL

762.

Failure to follow these instructions could result in

death or serious injury.

2 Speed, 2 Winding, Single Phase Motor

Single Speed, Single Phase, Dual Voltage

When ground required, attach to ground A or B with No. 6 thread forming screw. To

reverse, interchange T-5 and J-10 leads.

To reverse, interchange any 2 line leads.

2 Speed, 2 Winding, 3 Phase

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2 line leads

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and L

2

. For single

phase application, disregard L

3

. *Damper motors may be available in 115, 230 and

460 volt models. The damper motor nameplate voltage should be verified prior to con-

nection. ** A transformer may be provided in some installations to correct the damper

motor voltage to the specified voltage.

VCRD with Shade Pole or PSC Motors

White

Line

Black

Line

When ground required,

attach to ground A or B

with No. 6 thread forming

screw. To reverse, inter-

change T-1 and T-4

leads.

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

T-1

T-4

Ground B

L 2

L1

Ground A

Line

When ground is required, attach to ground A or B

with no. 6 thread forming screw. To reverse, in-

terchange T-1 and T-4.