Shaft speed, Belts, Replacement – COOK H-Series User Manual

Page 6: Changing shaft speed, Pulley and belt replacement, Bearing replacement, Propeller and shaft replacement precautions, Maximum rpm

6

Changing Shaft Speed

All belt driven H-Series fans with motors up to and includ-

ing 5HP are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are main-

tained.

Pulley and Belt Replacement

a. Clean the motor and fan shafts.

b. Loosen the motor plate mounting bolts to relieve the

belt tension. Remove the belt.

c. Loosen the pulley setscrews and remove the pulleys

from the shaft.

If excessive force is required to remove the pulleys, a

three-jaw puller can be used. This tool, however, can

easily warp a pulley. If the puller is used, inspect the

trueness of the pulley after it is removed from the shaft.

The pulley will need replacement if it is more than

0.020 inch out of true.

Pulley and Belt Replacement continued

d. Clean the bores of the pulleys and place a light coat of

oil on the bores.

e. Remove grease, rust and burrs from the shaft.

f. Place fan pulley on the fan shaft and the motor pulley

on the motor shaft. Damage to the pulleys can occur

when excessive force is used in placing the pulleys on

their respective shafts.

g. After the pulleys have been correctly placed back onto

their shafts, tighten the pulley setscrews.

h. Install the belts on the pulleys. Align and adjust the

belts to the proper tension as described in Belt and Pul-

ley Installation, page 2.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Remove the top cap or hood as necessary to gain

access to the fan.

b. Loosen the motor plate mounting bolts and remove the

drive belts.

c. Remove the propeller from the shaft.

d. Remove the four (4) bearing hold-down bolts and then

remove the shaft, bearings, and driven sheave from the

unit as an assembly.

e. Measure and record the location of the bearings and

sheave on the shaft. This will aid the reassembly.

f. Remove the anti-corrosion coating from the shaft with

a suitable degreaser and then remove the pulley from

the shaft.

g. Remove the bearing from the shaft using a bearing

puller.

h. Install the pulley in the correct location on the shaft

Secure the bearing hold-down bolts, but do not fully

tighten.

i. Align the setscrews on the bearings and tighten one

setscrew on each bearing.

j. Rotate the shaft to allow the bearing outer rings to find

their center of free movement.

k. Install the propeller on the shaft and adjust the bearing

position to center the propeller in the opening.

l. Tighten the hold-down bolts to the proper torque. Refer

to Torque Chart, page 4.

m. Turn the shaft by hand. Resistance should be the same

as it was before the hold-down bolts were fully tight-

ened.

n. Tighten the bearing setscrews to the specified torque.

o. Install the pulley and adjust the belt tension.

p. Reassemble the fan.

After 24 hours of continuous operation, tighten the set-

screws to the appropriate torque. This assures the full lock-

ing of the inner race to the shaft. Ensure the socket key or

driver is in good condition with no rounded corners. The

key should be fully engaged in the setscrew and held

squarely to prevent the rounding out of the setscrew socket

when applying maximum torque.

Propeller and Shaft Replacement Precautions

• If the shaft is dropped and bent, it may cause unbal-

anced operation of the fan.

• When handling the propeller separately from the shaft,

place a support through the hub for lifting, making sure

not to injure the finished bore of the propeller.

• Never allow the propeller to rest its entire weight on the

blades. The propeller and shaft can be lifted by slings

around the shaft on each side of the propeller so the

propeller is supported by its hub.

• If using a chain to lift the propeller, make sure there is

sufficient padding on the shaft and propeller. This pre-

vents the scoring of the shaft or injury to the propeller.

The chain or cable should be spread with timbers, or

braced by some other method to prevent damage to

the propeller side plates.

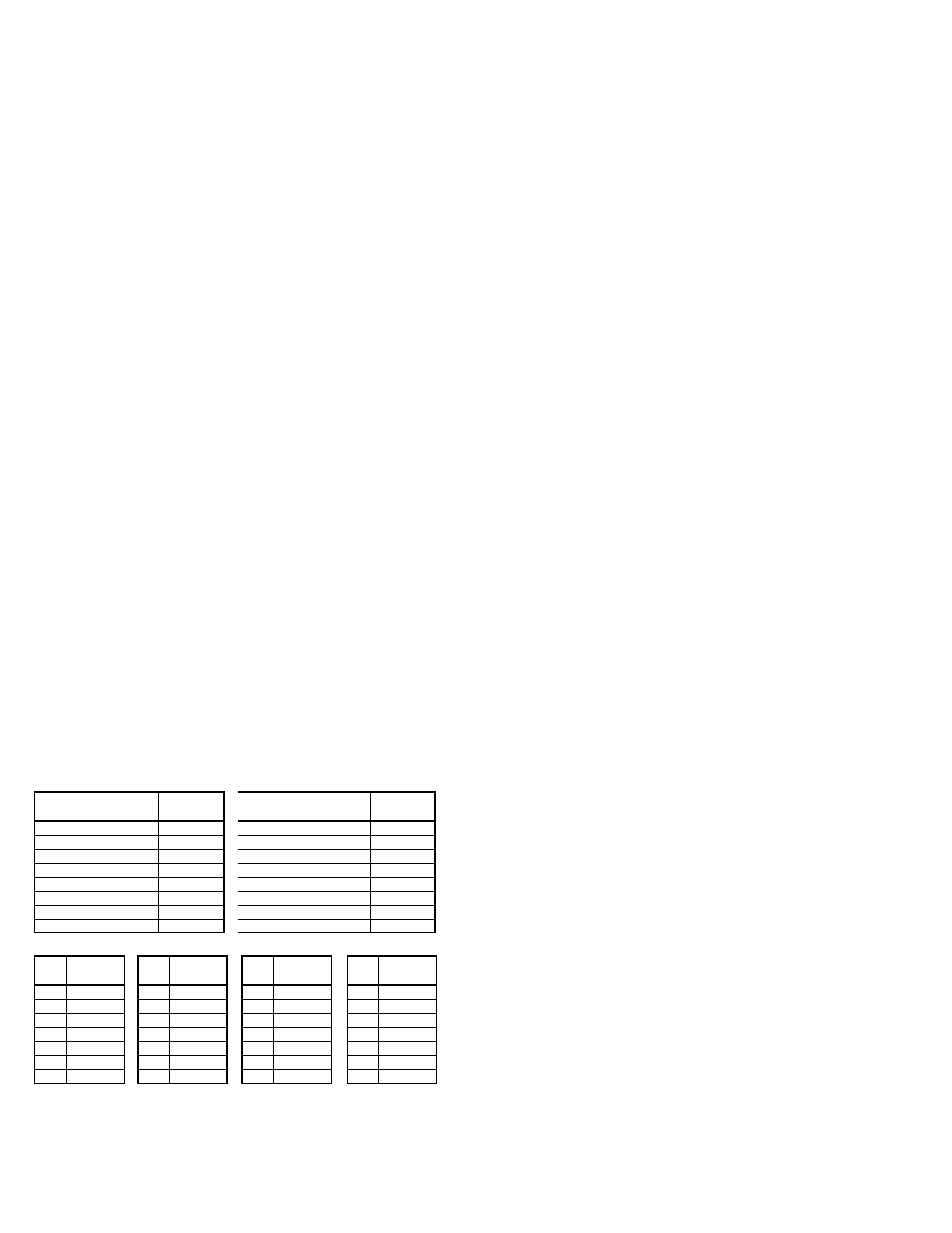

Maximum RPM

HXEL, HXSL, HXFL

Size

Maximum

RPM

HXEM, HXSM, HXFM

Size

Maximum

RPM

20

1276

20

1462

24

1126

24

1400

30

932

30

1184

36

720

36

864

42

610

42

718

48

516

48

598

54

478

54

522

60

450

60

539

Maximum RPM

HEE

Size

Maximum

RPM

HES

Size

Maximum

RPM

HEF

Size

Maximum

RPM

HER

Size

Maximum

RPM

24

1675

24

1630

24

1635

24

1635

30

1295

30

1330

30

1330

30

1325

36

1125

36

1165

36

1160

36

1145

42

880

42

885

42

880

42

920

48

822

48

830

48

816

48

818

54

776

54

742

54

735

54

748

60

636

60

642

60

634

60

642