Installation, Wiring diagrams, Damper – COOK H-Series User Manual

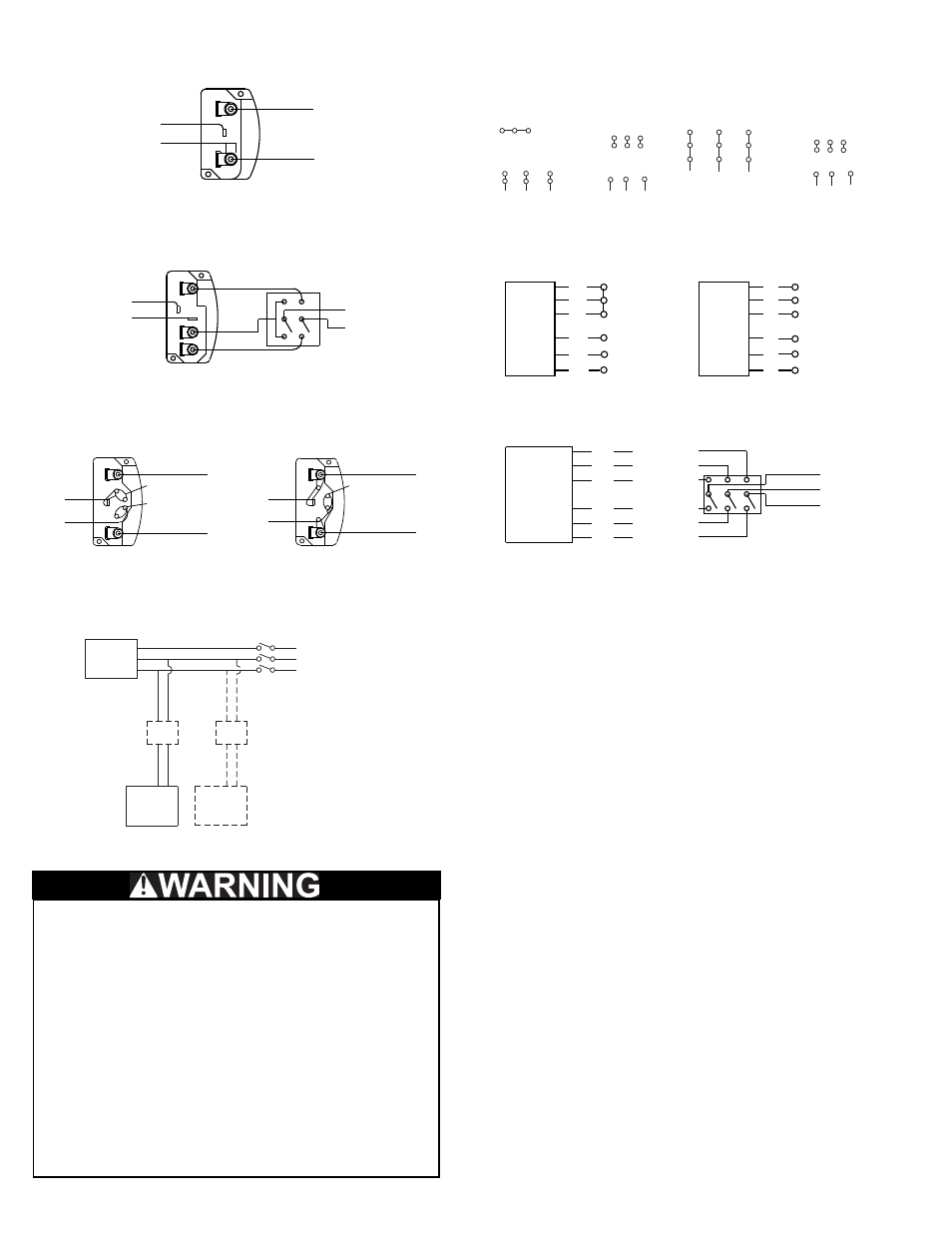

Page 2: Motor, 3 phase, 9 lead motor delta-connection, Single speed, single phase motor, Typical damper motor schematic

2

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Wiring Diagrams

Wiring Diagrams

When ground is required, attach to ground A or B with no. 6 thread forming

screw. To reverse, interchange T-1 and T-4.

Ground A

L

1

L

2

Line

T-1

T-4

Ground B

Single Speed, Single Phase Motor

To reverse, interchange any 2 line leads.

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

T-1

T-4

Ground B

Ground A

High Speed

Low Speed

L

1

L

2

Line

2 Speed, 2 Winding, Single Phase Motor

2 Speed, 1 Winding, 3 Phase Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

Together

Open

Low Speed

High Speed

Motor

Motor

1

2

3

4

5

6

L

1

L

2

L

3

L

1

L

2

L

3

1

2

3

4

5

6

Single Speed, Single Phase, Dual Voltage

2 Speed, 2 Winding, 3 Phase

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

Link A

Low Voltage

Ground A

Ground B

T-5

J-10

L

1

L

2

Line

T-5

J-10

Ground A

Ground B

Link A & B

High Voltage

L

1

L

2

Line

Link B

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2

line leads.

T

3

T

2

T

1

T

11

T

12

T

13

Low Speed

Low Speed

Low Speed

High Speed

High Speed

High Speed

L

1

L

2

L

3

Motor

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. **A transformer may be pro-

vided in some installations to correct the damper motor voltage to the

specified voltage.

Line

Line

Line

Damper Installation

If your fan is supplied with dampers, follow the directions

below. If your fan does not include dampers, proceed to

Motor Installation.

a. Place the damper inside the curb. Ensure the damper

will open freely for the correct direction of the airflow.

b. Secure to curb at the damper shelf.

c. Drill a hole in the curb shelf for conduit needed for

motor wiring.

d. Operate the dampers manually to ensure the blades

move freely. Dampers should be released from full

open position to check for proper closing.

Motor Installation

If your fan is a direct drive (model HEE-D, HES-D, HEF-D

or HER-D), proceed to Wiring Installation.

To prevent damage to the fan during shipping, motors 5

HP and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be field mounted.

Installation

The attachment of roof mounted fans to the roof curb

as well as the attachment of roof curbs to the building

structure must exceed the structural requirements

based on the environmental loading derived from the

applicable building code for the site. The local code

official may require variations from the recognized

code based on local data. The licensed engineer of

record will be responsible for prescribing the correct

attachment based on construction materials, code

requirements and environmental effects specific to

the installation.

Failure to follow these instructions could result in

death or serious injury.