Services, Shaft spee, Replacement – COOK LC User Manual

Page 5: Motor services, Changing shaft speed, Pulley and belt replacement, Bearing replacement, Maximum rpm

5

Direct Drive 1050/1075,1200,1300 &1500 rpm units use

a prelubricated sleeve bearing that has a oil saturated

wicking material surrounding it. The initial factory

lubrication is adequate for up to 10 years of operation

under normal conditions. However, it is advisable to add

lubricant after 3 years. Use only LIGHT grade mineral oil or

SAE 10W oil up to 30 drops. If the unit has been stored for

a year or more it is advisable to lubricate as directed above.

For direct drive units and other units in severe conditions,

lubrication intervals should be reduced to half.

Motors without sleeve bearings (as described above) will

have grease lubricated ball or roller bearings. Motor

bearings without provisions for relubrication will operate up

to 10 years under normal conditions with no maintenance.

In severe applications, high temperatures or excessive

contaminates, it is advisable to have the maintenance

department disassemble and lubricate the bearings after 3

years of operation to prevent interruption of service.

For motors with provisions for relubrication, follow

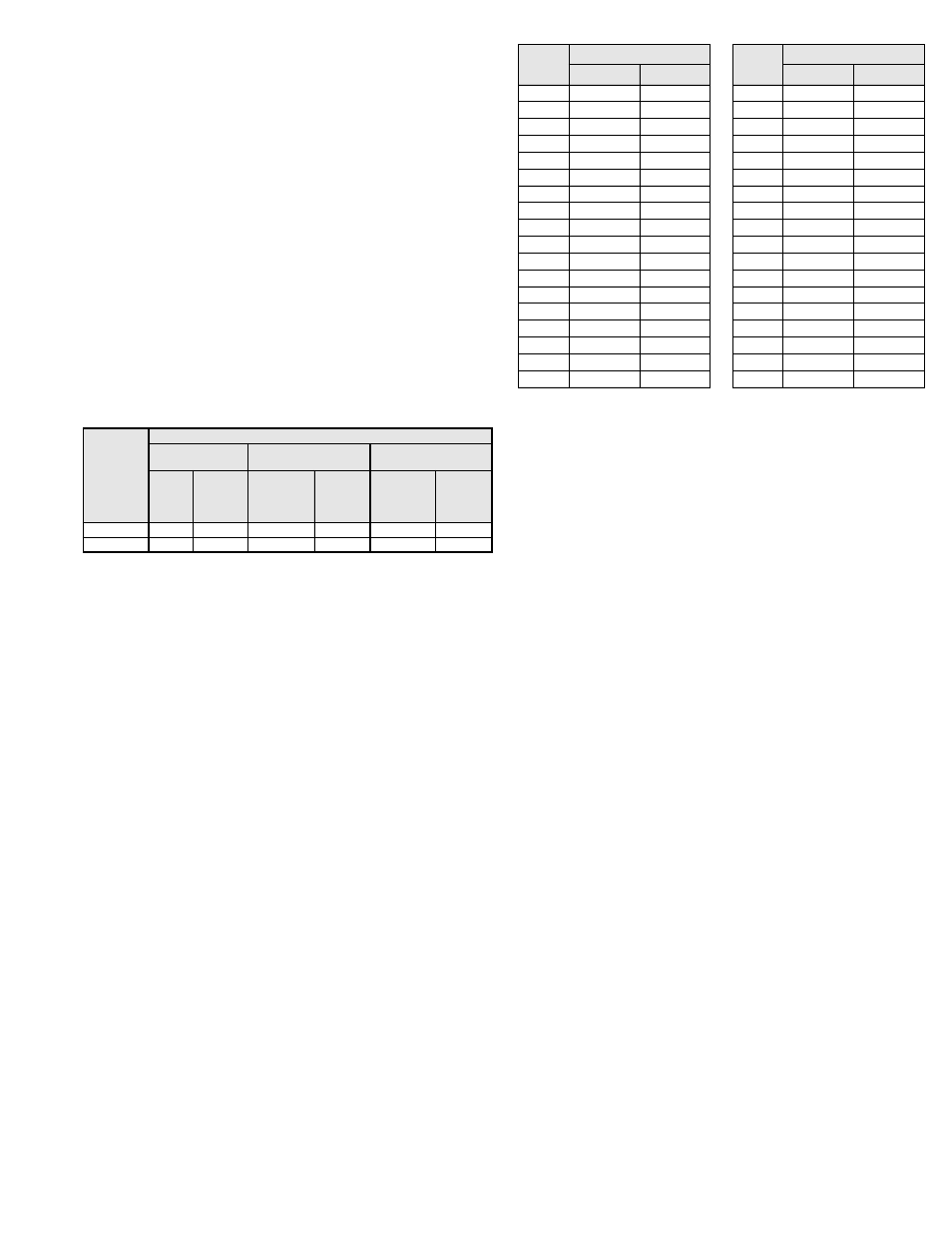

intervals of the table below.

Relubrication Intervals

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with a

compatable grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service

representative.

Changing Shaft Speed

All belt driven fans with motors up to and including 5HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are

maintained.

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800

RPM

and

less

Over

1800

RPM

1800 RPM

and less

Over

1800

RPM

1800 RPM

and less

Over

1800

RPM

Standard

3 yrs. 6 months

2 yrs.

6 months

1 yr.

3 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months

Maximum RPM

TLC-B

Size

Maximum RPM

HLC-B

Size

Maximum RPM

Standard Reinforced

Standard Reinforced

100

1755

-

100

1740

-

120

1730

-

120

1695

-

135

1750

-

135

1780

-

150

1640

-

150

1620

-

165

1325

-

165

1335

-

180

1490

-

180

1555

-

195

1325

-

195

1345

-

210

1275

1325

210

1245

1345

225

1135

1180

225

1140

1185

245

1015

-

245

1010

-

270

865

-

270

875

-

300

830

995

300

825

985

330

700

880

330

605

865

365

610

725

365

615

705

402

535

610

402

535

615

445

455

520

445

445

510

490

390

430

490

390

430

540

345

415

540

345

415

Pulley and Belt Replacement

a. Clean the motor and fan shafts.

b. Loosen the motor plate mounting bolts to relieve the

belt tension. Remove the belt.

c. Loosen the pulley setscrews and remove the pulleys

from the shaft.

If excessive force is required to remove the pulleys,

a three-jaw puller can be used. This tool,

however, can easily warp a pulley. If the puller is

used, inspect the trueness of the pulley after it is

removed from the shaft. The pulley will need

replacement if it is more than 0.020 inch out of

true.

d. Clean the bores of the pulleys and place a light coat of

oil on the bores.

e. Remove grease, rust and burrs from the shaft.

f. Place fan pulley on the fan shaft and the motor pulley

on the motor shaft. Damage to the pulleys can occur

when excessive force is used in placing the pulleys on

their respective shafts.

g. After the pulleys have been correctly placed back onto

their shafts, tighten the pulley setscrews.

h. Install the belts on the pulleys. Align and adjust the

belts to the proper tension as described in Belt and

Pulley Installation, page 1.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Loosen screws on bearing cover.

b. Push bearing cover toward the wheel. As the bearing

cover moves toward the wheel it will slide down to

reveal the bearings and shaft.

c. Remove the old bearing.

d. Remove any burrs from the shaft by sanding.

e. Slide new bearings onto the shaft to the desired loca-

tion and loosely mount bearings onto the bearing sup-

port. Bearing bolts and setscrews should be loose

enough to allow shaft positioning.

f. Correctly position the wheel and tighten the bearing

bolts securely to the bearing support.