Services, Shaft speed, Replacement – COOK CFS User Manual

Page 6: Motor services, Changing shaft speed, Pulley and belt replacement, Bearing replacement

6

For motors with provisions for relubrication, follow inter-

vals of the table below.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with a

compatable grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or

your nearest authorized electric motor service representa-

tive.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

(184T max.) are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing.

If the pulley has multiple grooves, all must be adjusted

to the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in

the groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in

the groove (larger pitch diameter). Ensure that the RPM

limits of the fan and the horsepower limits of the motor

are maintained.

Pulley and Belt Replacement

a. Remove pulleys from their respective shafts.

b. Clean the motor and fan shafts.

c. Clean bores of pulleys and coat the bores with heavy

oil.

d. Remove grease, rust, or burrs from the pulleys and

shafts.

e. Remove burrs from shaft by sanding.

f. Place fan pulley on fan shaft and motor pulley on its

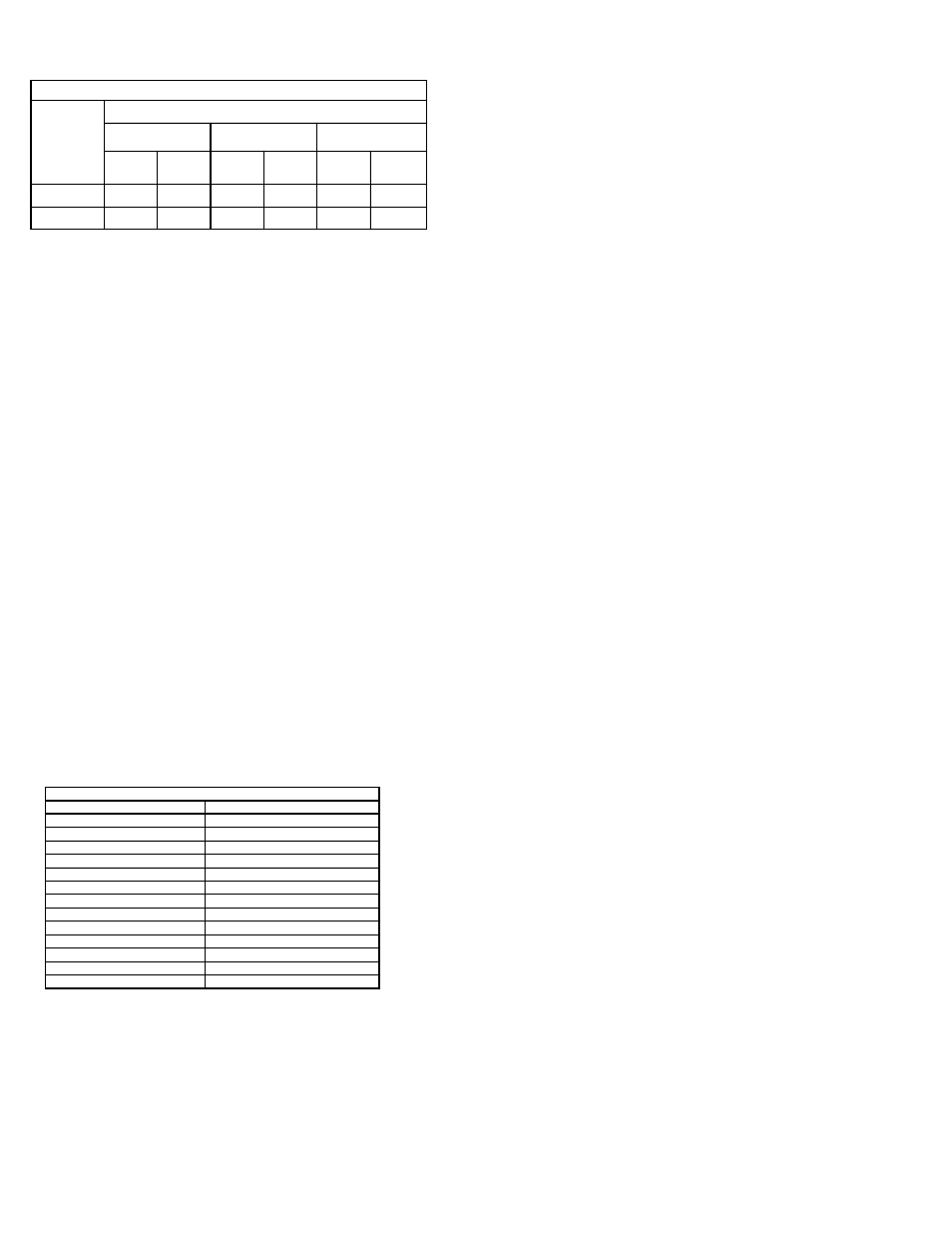

Relubrication Intervals

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

Standard

3 yrs.

6 months

2 yrs.

6 months

1 yr.

3 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their

respective shafts.

g. Tighten in place.

h. Install belts on pulleys and align as described in the

Belt and Pulley Installation section.

Bearing Replacement

The fan bearings are pillow block ball bearings. Bearings

should be replaced individually for each side of fan.

An emery cloth or file may be needed to remove imper-

fections in the shaft left by the setscrews.

a. Remove belts.

b. If replacing drive side bearing, mark location of pulley

and remove.

c. Mark bearing location on bearing support and loosen

bearing hold-down bolts.

d. Support shaft to remove weight from bearing.

e. Remove anti-corrosion coating from the shaft with a

suitable degreaser.

f. Remove the bearing from the shaft using a bearing

puller. If a bearing puller is not available, tap on the

bearing with a wood block and hammer to remove it.

g. Remove the bearing from the shaft using a bearing

puller. If a bearing puller is not available, tap on the

bearing with a wood block and hammer to remove it.

h. Smooth and clean the shaft and bearing bore thor-

oughly.

i. Place the bearings into position making sure they are

not on a worn section of the shaft. Tapping the inner

ring face with a soft driver may be required. Do not

hammer on the housing.

j. The outer ring of the bearing is spherical and swivels in

the housing to compensate for misalignment. Secure

hold-down bolts, but do not fully tighten.

k. Align the setscrews on the bearings and tighten one

setscrew on each bearing.

l. Rotate the shaft to allow the bearing outer rings to find

their center of free movement.

m. Tighten hold-down bolts to proper torque.

n. Turn the shaft by hand. Resistance should be the

same as it was before hold-down bolts were fully tight-

ened.

o. Tighten bearing setscrews to specified torque. Refer

to Torque chart.

p. Re-install the pulley and adjust the belt tension.

q. Repeat process for opposite bearing.

r. Test run the fan and trim the balance as necessary

(.0785 in/sec max.).

s. Retighten setscrews on bearings, sheave, and wheel.

Recheck belt tension and adjust as needed.

Speed Limit Table

CFS Sizes

Speed Limit

120

3,714

135

3,307

150

2,751

165

2,374

180

2,176

195

2,009

210

1,865

225

1,741

245

1,631

270

1,443

300

1,262

330

1,147

365

1,038