Inspection, Filters, Maintenance – COOK CFS User Manual

Page 5: Bearings, Start up, Lubrication - fan bearings, Lubrication - motor bearings

5

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for squeal-

ing).

• Improper motor amperage or voltage.

NOTICE! If a problem is discovered, immediately

shut the fan off. Lock out all electrical power and check

for the cause of the trouble. See Troubleshooting.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

the Conditions Chart.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension, bolts, setscrews, and motor mount-

ing bolts. Adjust and tighten as necessary.

Filters

Filter inspection and cleaning intervals can vary from

once a week to twice per year depending on contaminant

present and acceptable pressure drops across the filter.

Under most conditions filters may be cleaned with hot

water and a mild soap solution (such as dish washing liq-

uid) or steam. Some caustic cleaners will damage the filter.

If in doubt, please consult the factory for a compatibility list.

High pressure spray washers should be limited to

2,000psi operating pressure. Every attempt should be

made to remove the contaminants from the filter in a “back-

wash” flow (note airflow arrow on the filter frame). Once the

filter is dry, it may be returned to the appropriate filter racks

in the same orientation (airflow direction) as they were

removed.

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating con-

ditions and location of the fan.

It is recommended the following inspection be conducted

twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary. Worn setscrews should be replaced imme-

diately.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. Refer

to Belt and Pulley Installation, page 3.

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect variable inlet vanes for freedom of operation

and excessive wear. The vane position should agree

with the position of the control arm. As the variable inlet

vanes close, the entering air should spin in the same

direction as the wheel.

• Inspect springs and rubber isolators for deterioration

and replace as needed.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel

and housing prevent imbalance and damage.

Lubrication - Fan Bearings

Bearings are lubricated through a grease fitting on the

exterior of the fan housing and should be lubricated by the

schedule, Lubrication Conditions Chart.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can burst

seals thus reducing bearing life.

Before lubricating, the grease nipple and immediate

vicinity should be thoroughly cleaned without the use of

high pressure equipment. The grease should be supplied

slowly as the bearing rotates until fresh grease slips past

the seal. Excessive pressure should be avoided to prevent

seal damage.

Use no more than three injections with a hand-operated

grease gun.

Exceptions to the greasing interval chart:

• Periodic Applications (any break of one week or

more): it is recommended that full lubrication be performed

prior to each break in operation.

• Higher Temperature: it is recommended to halve the

intervals for every 30

F increase in operating temperature

above 120

F not to exceed 230F for standard bearings;

High Temperature bearings (optional) can operate up to

400

F.

Loren Cook Company uses petroleum lubricant in a lith-

ium base. Other types of grease should not be used unless

the bearings and lines have been flushed clean. If another

type of grease is used, it should be a lithium-based grease

conforming to NLGI grade 2 consistency.

A NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its tempera-

ture range is from -30

F to +200F and capable of intermit-

tent highs of +250

F.

Lubrication - Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below. Motor bearings without pro-

visions for relubrication will operate up to 10 years under

normal conditions with no

maintenance. In severe applications, high temperatures or

excessive contaminates, it is advisable to have the mainte-

nance department disassemble and lubricate the bearings

after 3 years of operation to prevent interruption of service.

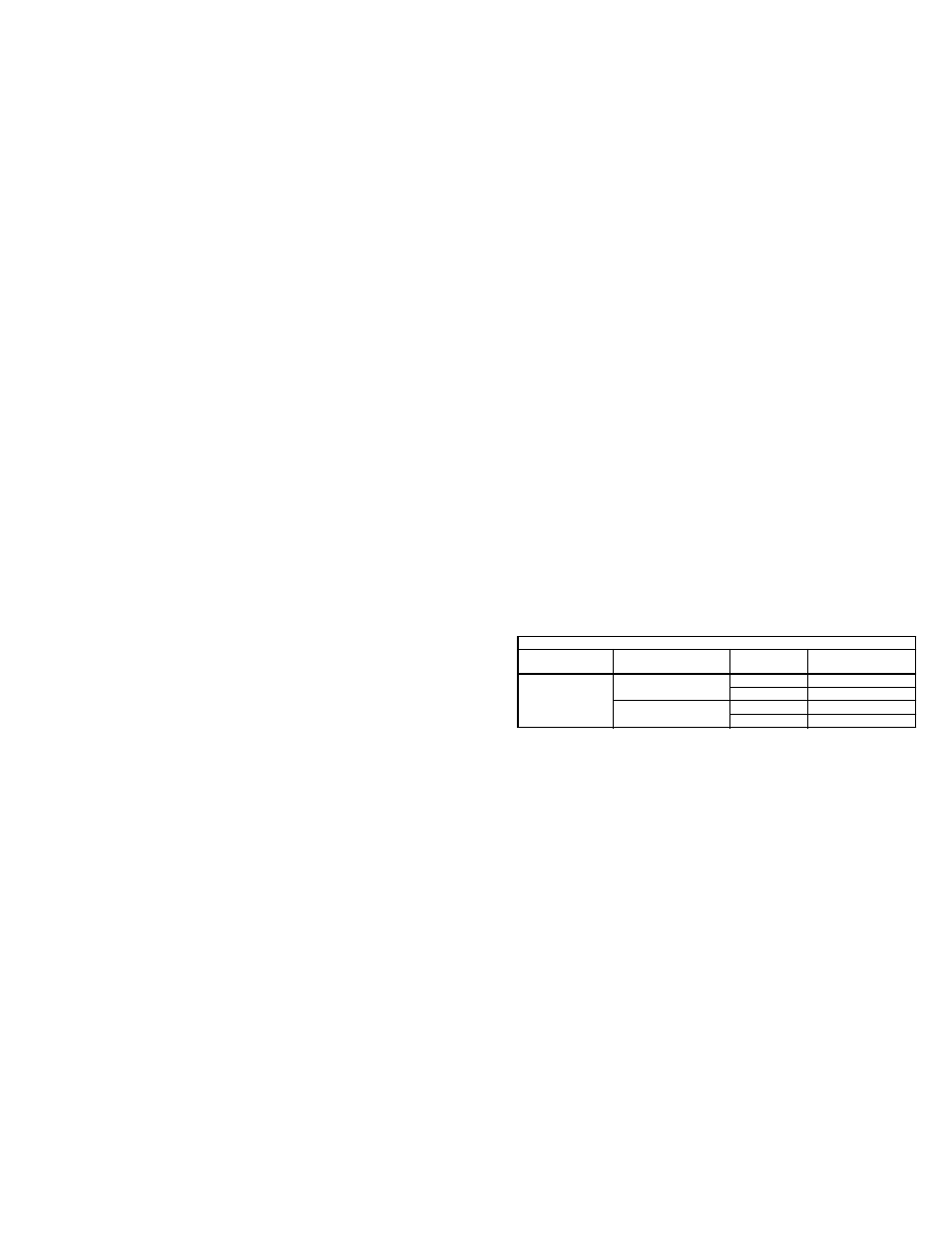

Lubrication Conditions Chart

Fan Class

Fan Status

Shaft Size

Maximum Interval

(operational hrs)

Centrifugal Blower

Class I

Normal Conditions

(Clean, Dry & Smooth)

> 1-1/2”

10,000

< 1-1/2”

2,000

Extreme Conditions

(Dirty/Wet/Rough)

> 1-1/2”

2,000

< 1-1/2”

400