Damper, Wheel, Variable frequency – COOK CFS User Manual

Page 2: Use of variable frequency drives

2

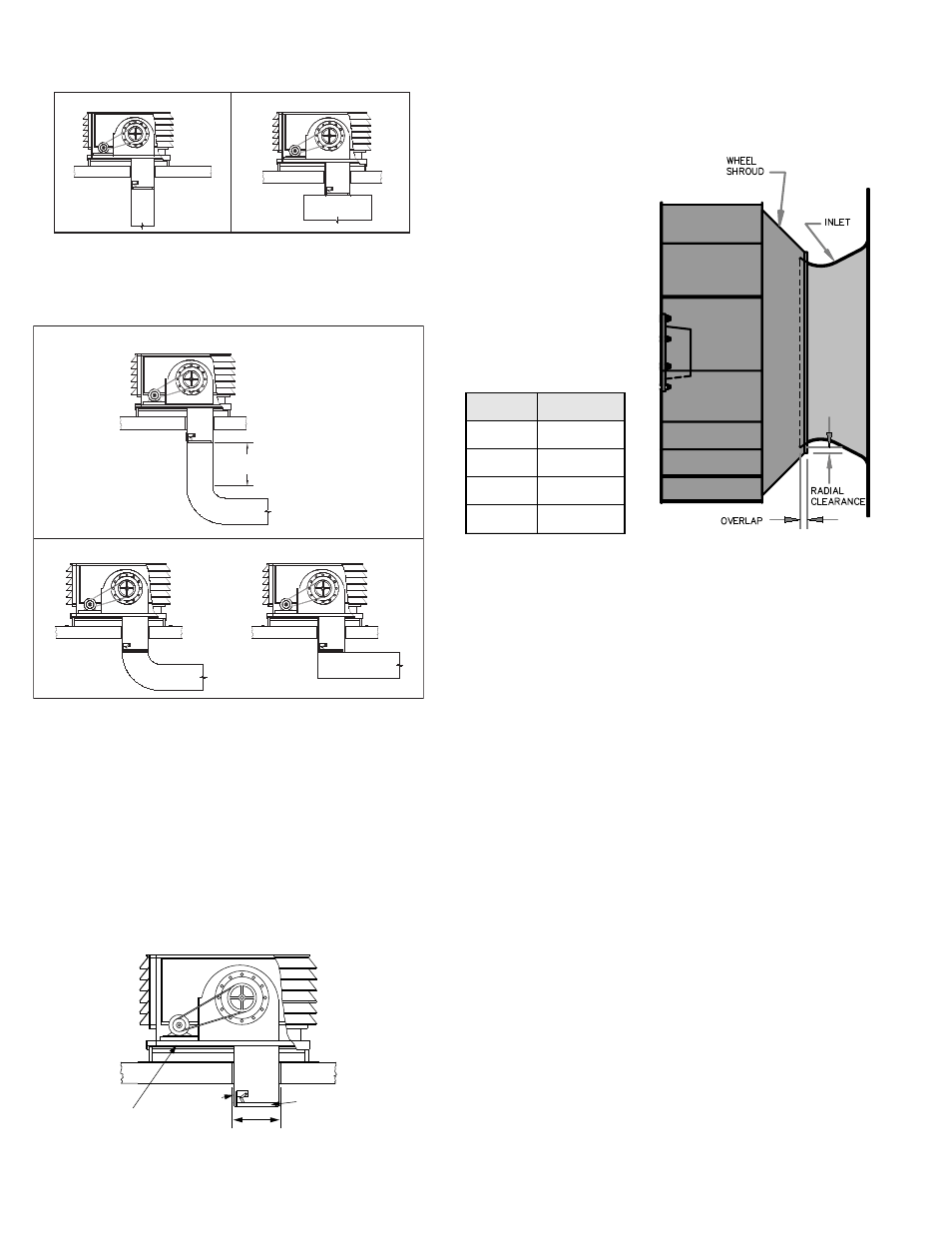

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to wheel/inlet draw-

ing for correct overlap.

Adjust the overlap by

loosening the wheel hub

and moving the wheel along

the shaft to obtain the cor-

rect value.

A uniform radial gap

(space between the edge of

the cone and the edge of

the inlet) is obtained by

loosening the inlet cone

bolts and repositioning the

inlet cone.

Use of Variable Frequency Drives

Motors -

Motors that are to be operated using a Variable Fre-

quency Drive (VFD) must be VFD compatible. At a mini-

mum, this must be a Premium Efficiency motor with Class F

insulation. Motors that are not supplied by Loren Cook

Company should have the recommendation of the motor

manufacturer for use with a VFD.

Grounding -

The fan frame, motor and VFD must be connected to a

common earth ground to prevent transient voltages from

damaging rotating elements.

Wiring -

Line reactors may be required to reduce over-voltage

spikes in the motors. The motor manufacturer should be

consulted for recommended line impedence and usage of

line reactors or filters, if the lead length between the VFD

and the motor exceeds 10 feet (3m).

Fan -

It is the responsibility of the installing body to perform

coast-down tests and identify any resonant frequencies

after the equipment is fully installed. These resonant fre-

quencies are to be removed from the operating range of

the fan by using the “skip frequency” function in the VFD

programming. Failure to remove resonant frequencies

from the operating range will decrease the operating life of

the fan and void the warranty.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor name-

plate.

Size

Overlap

100 - 165

3/16”

180 - 245

1/4”

270 - 300

5/16”

330 - 365

3/8”

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost efficiency because it doesn’t allow for a static regain.

Discharge Duct Turns

Where possible, allow 3 duct diameters between duct

turns or elbows and the fan outlet. Refer to Discharge Duct

Turns drawing on Page 2.

Damper and Curb Installation

a. Minimum roof opening dimensions can be found

within the CFS catalog.

b. The optional duct adapter fits on the curb to locate the

top of the duct before the fan is installed. Ductwork

requires additional support.

c. The typical damper try (optional) extends below the

curb top 38 inches. A clear 17-1/2 inches is required

to access the damper tray panel (see drawing above).

Should a longer damper tray be required, extended

lengths are available.

NOTICE! It may be necessary to add support beneath

the load carrying sides of the blower and curb.

Correct

Incorrect

Correct

MIN

3 DIA.

Incorrect

Minimum

Roof Opening

Motorized

Intake Damper

Damper Tray

Duct Adapter

Damper and Curb Installation Components