Wheel, Wheel replacement, Recommended puller – COOK ACSC User Manual

Page 5: Wheel-to-inlet clearance

5

Wheel Replacement

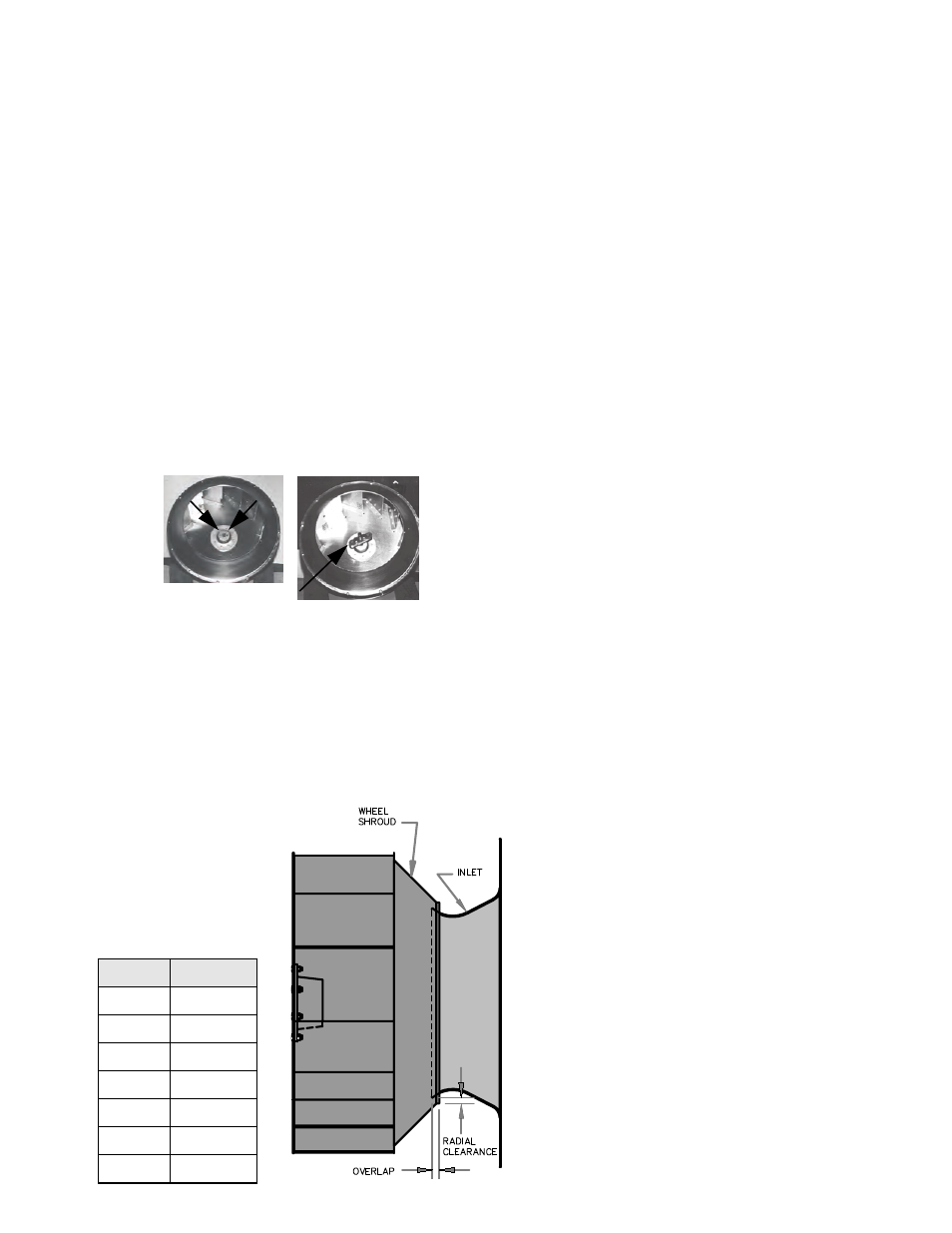

1. Drill two holes approximately centered between the

shaft and the edge of the hub OD with the following

dimensions:

• 1/4" diameter

• 3/8" to 1/2" deep

• 180° apart in face of hub

2. Tap 1/4" holes to 5/16" thread with the 5/16" hole tap.

Do not drill or tap any larger than recommended.

• 1/4" diameter

• 3/8" to 1/2" deep

• 180° apart in face of hub

3. Tap 1/4" holes to 5/16" thread with the 5/16" hole tap.

Do not drill or tap any larger than recommended.

4. Screw the puller arms into the tapped holes full depth

of threads (3/8" to 1/2" approximately). Align center of

puller with center of shaft. Make certain all setscrews in

hub (normally a quantity of two) are fully removed.

Work puller slowly to back wheel off the shaft.

Recommended Puller

Lisle No. 45000 Sterling Wheel Puller. This puller is avail-

able at most automotive parts retail outlets.

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to wheel/inlet draw-

ing for correct overlap.

Adjust the overlap by loosening the wheel hub and mov-

ing the wheel along the shaft to obtain the correct value.

A uniform radial gap

(space between the edge of

the cone and the edge of

the inlet) is obtained by

loosening the inlet cone

bolts and repositioning the

inlet cone.

Size

Overlap

100 - 165

3/16”

180 - 245

1/4”

270 - 300

5/16”

330 - 365

3/8”

402

7/16”

445 - 490

1/2”

540 - 730

13/16”

Above - Drilled hole placement.

Right - Wheel puller.