Operation, Start, Inspection – COOK ACSC User Manual

Page 3: Maintenance, Bearings, Pre-start checks, Start-up, 30 minute interval, 8 hour interval, 24 hour interval

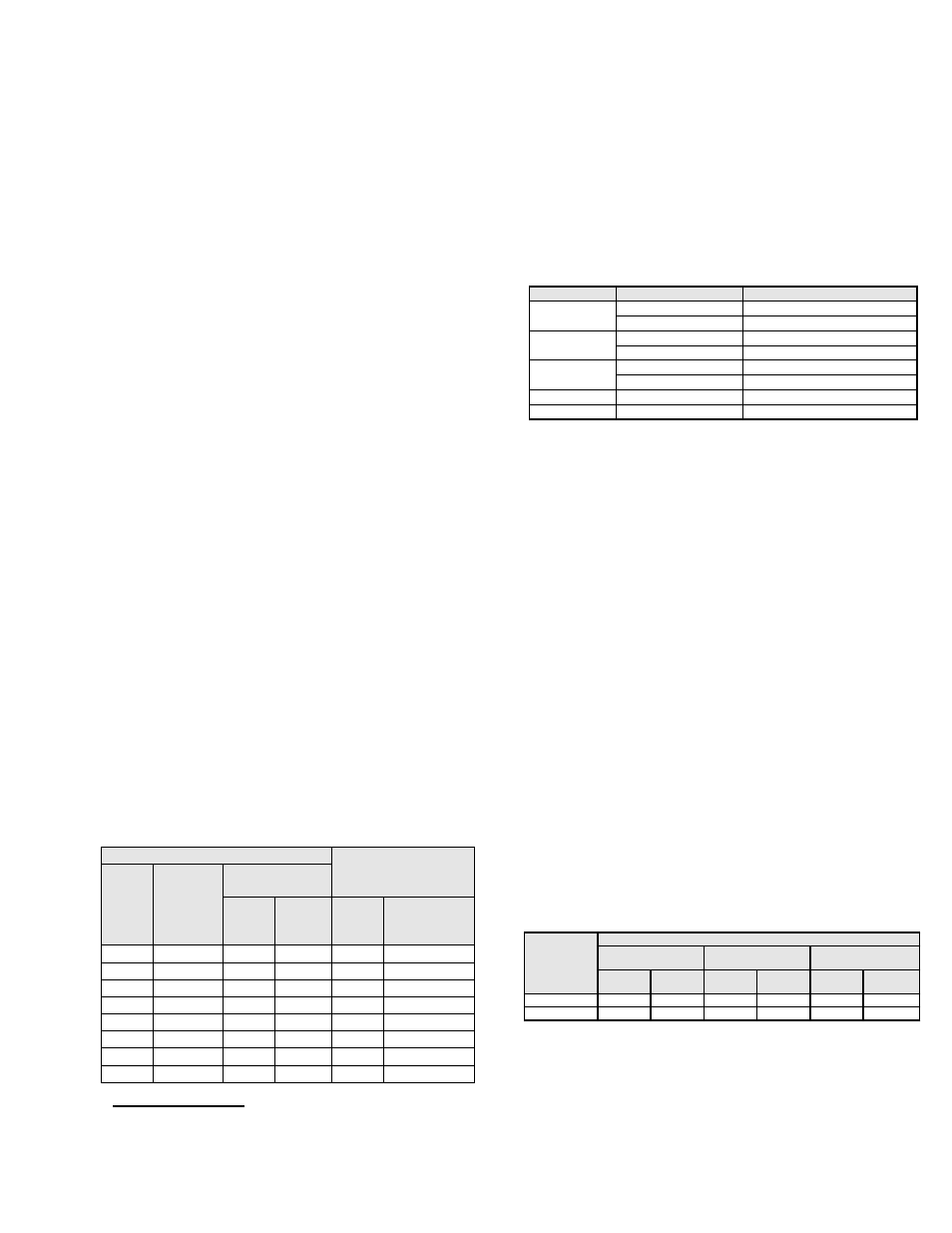

Setscrews

Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque Inch-lbs.

Min.

Max.

Size

Wrench

Torque (inch-

lbs)

No.10

3/32”

28

33

3/8”-16

240

1/4”

1/8”

66

80

1/2”-13

600

5/16”

5/32”

126

156

5/8”-11

1200

3/8”

3/16”

228

275

3/4”-10

2100

7/16”

7/32”

348

384

7/8”-9

2040

1/2”

1/4”

504

600

1”-8

3000

5/8”

5/16”

1104

1200

1-1/8”-7

4200

3/4”

3/8”

1440

1800

1-1/4”-7

6000

3

Operation

Pre-Start Checks

1. Lock out all the primary and secondary power

sources.

2. Inspect and tighten fasteners and setscrews, particu-

larly fan mounting and bearing fasteners Refer to

Torque chart.

3. Inspect belt tension and pulley alignment. Refer to

Belt and Pulley Installation, page 3.

d. Inspect motor wiring. Refer to Wiring Installation.

4. Ensure belt touches only the pulleys.

5. Rotate the wheel to ensure it rotates freely.

6. Ensure fan and ductwork are clean and free of debris.

7. Close and secure all access doors.

8. Restore power to fan.

Start-up

Turn on the fan. In variable speed units, set the fan to

its lowest speed. Inspect for the following:

• Direction of rotation

• Excessive vibration

• Unusual noise

• Bearing noise

• Improper belt alignment or tension (listen for squeal-

ing)

• Improper motor amperage or voltage

If a problem is discovered, immediately shut the fan

off. Lock out all electrical power and check for the

cause of the trouble. Refer to Troubleshooting on

page 5.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory oper-

ation. During the inspections, stop the fan and inspect as

instructed.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

Maintenance

Fan Bearings

Recommended Torque for Setscrews/Bolts (IN/LB)

NOTICE! The fan bearings are provided

prelubricated. Any specialized lubrication instructions

on fan labels supersedes information provided herein.

Bearing grease is a petroleum lubricant in a lithium

base conforming to a NLGI #2 consistency. If user

desires to utilize another type of lubricant, they take

responsibility for flushing bearings and lines, and

maintaining a lubricant that is compatible with the

installation.

A NLGI #2 grease is a light viscosity, low-torque, rust-

inhibiting lubricant that is water resistant. Its temperature

range is from -30°F to 200°F and capable of intermittent

highs of 250°F.

Bearings should be relubricated in accordance with the

condition chart above.

For best results, lubricate the bearing while the fan is in

operation. Pump grease in slowly until a slight bead forms

around the bearing seals. Excessive grease can damage

seal and reduce life through excess contamination and/or

loss of lubricant.

In the event that the bearing cannot be seen, use no

more than three injections with a hand operated grease

gun.

Motor Bearings

Motors are provided with prelubricated bearings. Any

lubrication instructions shown on the motor nameplate

supersede instructions below.

Motor bearings without provisions for relubrication will

operate up to 10 years under normal conditions with no

maintenance. In severe applications, high temperatures or

excessive contaminates, it is advisable to have the

maintenance department disassemble and lubricate the

bearings after 3 years of operation to prevent interruption

of service. For motors with provisions for relubrication,

follow intervals of the table below.

NOTICE! Motors are provided with a polyurea

mineral oil NGLI #2 grease. All additions to the motor

bearings are to be with a compatible grease such as

Exxon Mobil Polyrex EM and Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Conditions Chart

For moist or otherwise contaminated installations; divide the interval by

a factor of 3. For vertical shaft installations divide the interval by a factor

of 2.

RPM

Temp °F

Greasing Interval

Up to 1000

-30 to 120

6 months

120 to 200

2 months

1000 to 3000

-30 to 120

3 months

120 to 200

1 month

Over 3000

-30 to 120

1 month

120 to 200

2 weeks

Any Speed

< -30

Consult Factory

Any Speed

> 200

1 week

Relubrication Intervals

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

1800 RPM

and less

Over 1800

RPM

Standard

3 yrs.

6 months

2 yrs.

6 months

1 yr.

3 months

Severe

1 yr.

3 months

1 yr.

3 months 6 months 1 months