Inspection, Routine inspection, Typical damper motor schematic – COOK ACSC User Manual

Page 2

2

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connec-

tion with the terminal box at the end of the motor.

NOTICE! Follow the wiring diagram in the discon-

nect switch and the wiring diagram provided with the

motor. Correctly label the circuit on the main power

box and always identify a closed switch to promote

safety (i.e., red tape over a closed switch).

Final Installation Steps

1. Ensure fasteners and set screws, particularly fan

mounting and bearing fasteners are tightened

according to the recommended torque shown in the

table on page 2, Recommended Torque for Set-

screws/Bolts.

2. Inspect for correct amperage with an ammeter and

correct voltage with a voltmeter.

3. Ensure that all accessories are installed.

4. Test the fan to be sure the rotation is the same as

indicated by the arrow marked ‘Rotation’.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause

serious damage. For 3-phase motors, if the fan is

running in the wrong direction, check the control

switch. It is possible to interchange two leads at

this location so that the fan is operating in the

correct direction.

5. Inspect wheel-to-inlet clearance. Wheels may shift in

shipment. To realign wheel-to-inlet, shift upper bear-

ing so there is an equal radial clearance between the

wheel and inlet.

Wiring Diagrams

Single Speed, Single Phase Motor

2 Speed, 2 Winding, Single Phase Motor

Single Speed, Single Phase, Dual Voltage

When ground required, attach to ground A or B with No. 6 thread forming screw.

To reverse, interchange T-5 and J-10 leads.

When ground required,

attach to ground A or B

with No. 6 thread forming

screw. To reverse, inter-

change T-1 and T-4

leads.

Ground A

Ground B

T-1

T-4

Low Speed

High Speed

L 1

L 2

Line

Ground B

J-10

T-5

Ground A

Link A

Link B

Low Voltage

Line

L 2

L 1

Ground A

Link A & B

L1

L 2

Line

Ground B

T-5

J-10

To reverse, interchange any 2 line leads.

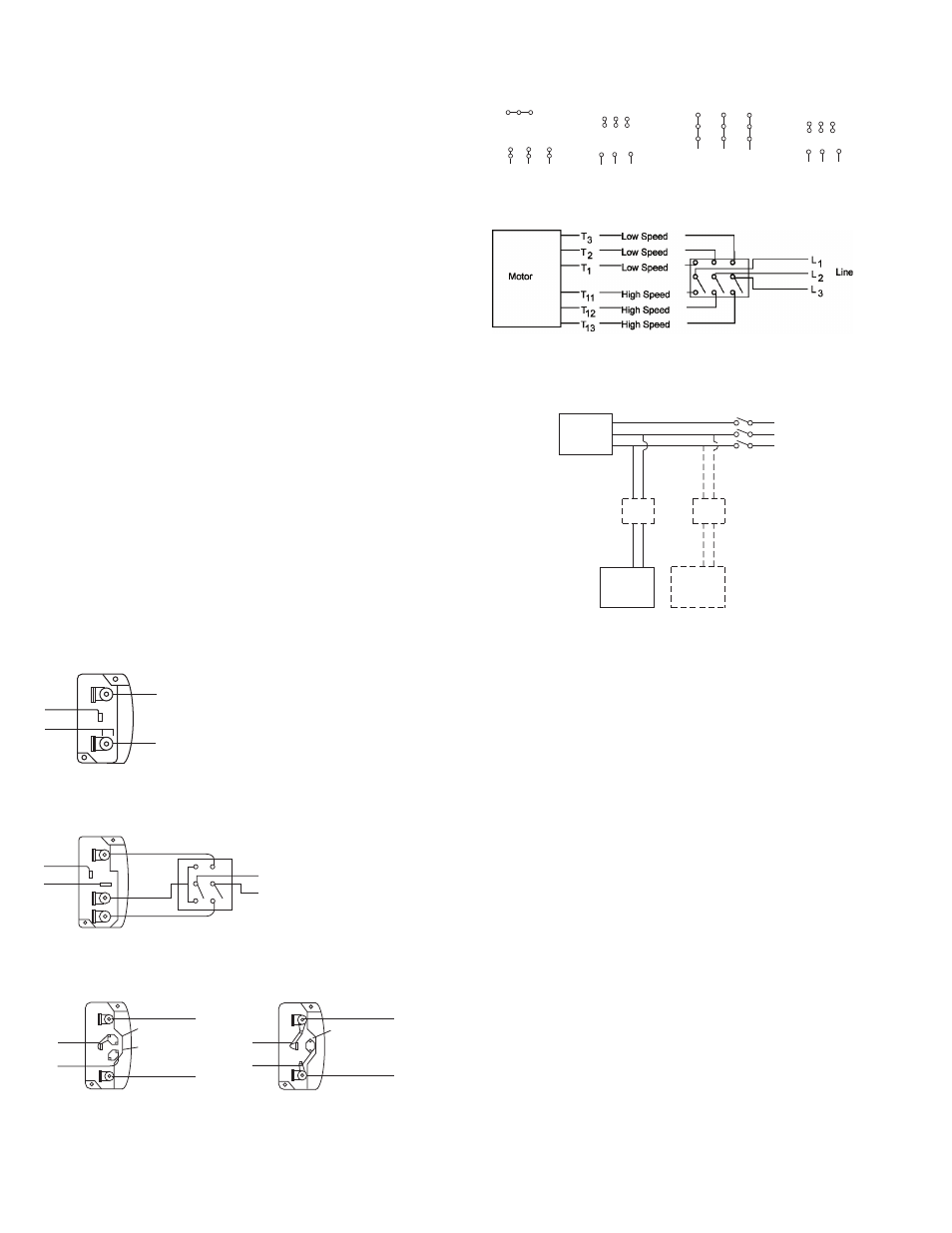

2 Speed, 2 Winding, 3 Phase

To reverse: High Speed-interchange leads T

11

and T

12

.

Low Speed-interchange leads T

1

and T

2

. Both Speeds-interchange any 2 line

leads

Typical Damper Motor Schematic

For 3 phase, damper motor voltage should be the same between L

1

and

L

2

. For single phase application, disregard L

3

. *Damper motors may be

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be

provided in some installations to correct the damper motor voltage to the

specified voltage.

Routine Inspection

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating

conditions and location of the fan.

ACSC fan is intended for general ventilation, and is UL

listed for Smoke Control Systems. The fan should not

be used to exhaust corrosive or contaminated air.

Regular, twice per year, inspections are recommended

and may be required per local codes.

Contact the local code authority for inspection require-

ments.

• Inspect bolts and setscrews for tightness. Tighten as

necessary. Refer to Torque chart.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. Refer

to Belt and Pulley Installation, page 3.

• Bearings should be inspected as recommended in the

Conditions Chart.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

4 5 6

1

7

2

8

3

9

L1 L2 L3

4 5 6

7 8 9

1 2

3

L1 L2 L3

Low Voltage

208/230 Volts

High Voltage

460 Volts

3 Phase, 9 Lead Motor

Y-Connection

7

1

6

7 8 9

4 5 6

1 2

3

Low Voltage

208/230 Volts

High Voltage

460 Volts

8

2

4

9

3

5

L1

L3

L2

L1

L3

L2

3 Phase, 9 Lead Motor

Delta-Connection

Fan

Motor

Damper

Motor*

Second

Damper

Motor

Transformer**

Transformer**

L3

L2

L1

T-1

T-4

Ground B

L 2

L1

Ground A

Line

When ground is required, attach to ground A or B

with no. 6 thread forming screw. To reverse, in-

terchange T-1 and T-4.