F. troubleshooting – Karcher HDR 777-VA User Manual

Page 31

HDR 777

English

5.959-106 A2006570 09/03

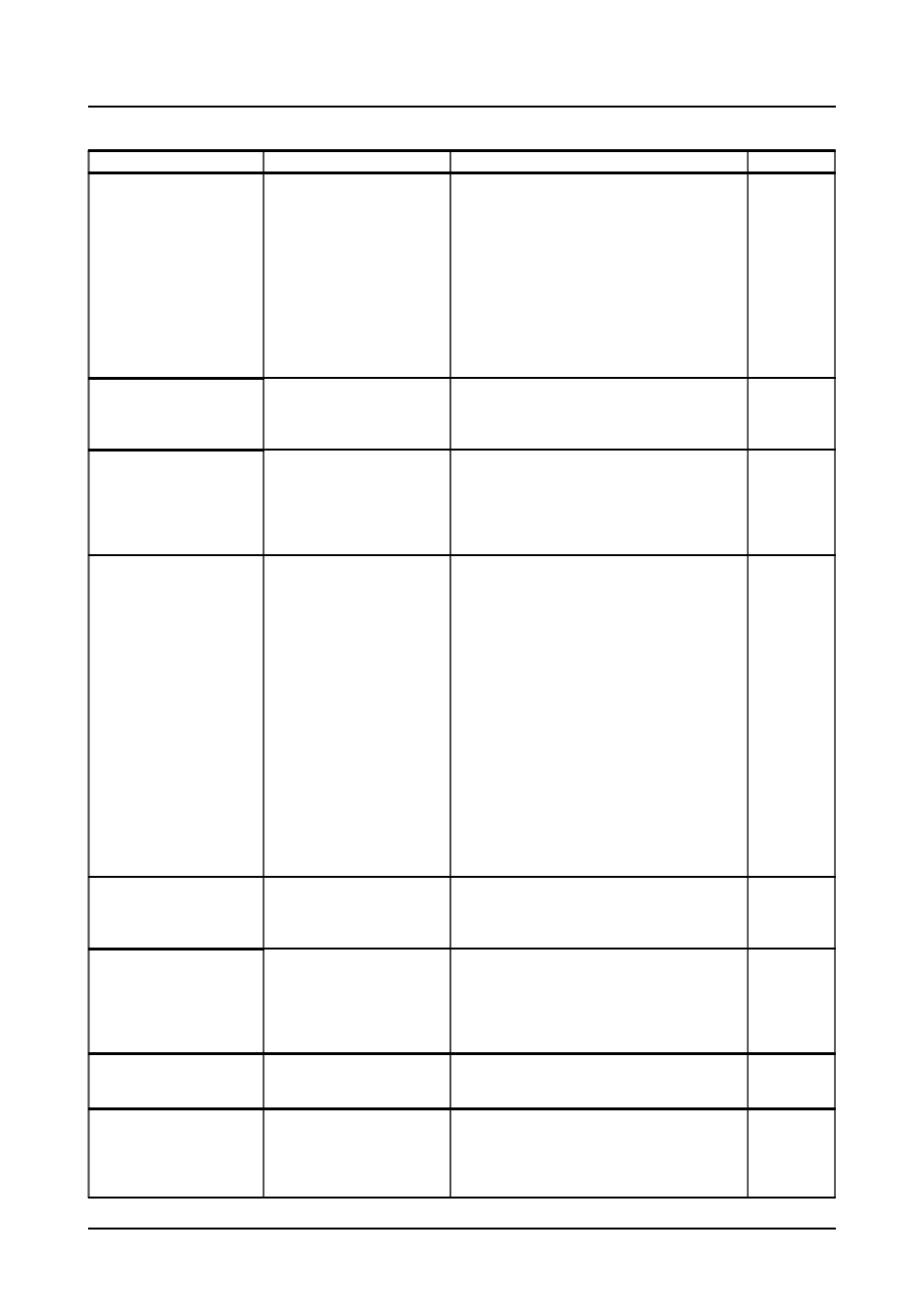

F. Troubleshooting

F2

Problem

Possible cause

Remedy

By whom

Strong odour nuisance

Disinfectant metering tank

(6) empty

Metered quantity in (6) too

low

Metering solenoid valve

defective

Disinfectant no longer active

Refill tank

Increase metered quantity

Replace solenoid valve

Check disinfectant and if necessary replace

with new disinfectant

Operator

Customer

Service

Customer

Service

Operator/

Customer

Service

Very high consumption of

degerminating

Degerminating agent

metering (6) set too high

Defective solenoid valve

Reduce dosage

Replace solenoid valve

Customer

Service

Industrial water storage

tank (9) overflows

Level sensor in the storage

tank (9) soiled or defective

Solenoid valve for fresh

water inlet (11) soiled or

defective

Clean or replace

Clean or replace

Operator/

Customer

Service

Reaction tank (3) is not

fully drained

Storage tank for industrial

water (9) full

Level sensor im storage tank

(9) soiled or defective

Hose or pumps (16 or 17)

between the reaction tank

(3) and filter unit blocked

Dirty agitator shaft or

problem with contacts

Agitator shaft has become

detached from motor shaft

In recycling mode wait for the water to be

consumed, otherwise clean or replace the

supply pump for the high-pressure cleaner

(12)

Clean or replace

Clean or replace

Clean or replace

Re-attach shaft and tighten coupling securely

Operator/

Customer

Service

Operator/

Customer

Service

Operator/

Customer

Service

Operator/

Customer

Service

Customer

Service

Stirrer motor and drainage

pumps (16, 17) do not

switch off after draining the

reaction tank

Dirty agitator shaft or

problem with contacts

Clean or replace

Operator/

Customer

Service

Cleavage powder is not

pumped into the reaction

tank

Metering aperture (f) or

metering device blocked up

with moist splitting agent

No voltage supply to metering

motor, or motor is defective

Empty splitting agent out of metering unit (5)

Clean out aperture or metering device

Add dry splitting agent

Check supply voltage or replace motor, if

required

Operator

Customer

Service

Motor for metering splitting

agent is running although

there is no splitting agent left

Dirty or defective level

sensor

Clean or replace level sensor

Operator/

Customer

Service

Stirrer shaft in the reaction

tank (3) doesn’t rotate

No voltage supplied to agitator

motor, or motor is defective

Agitator shaft has become

detached from motor shaft

Check supply voltage or replace motor, if

necessary

Re-attach shaft and tighten coupling securely

Customer

Service