Karcher STH 5-56 User Manual

Page 17

-

7

The engine manufacturer assumes liability

for all engine-related problems as regards

output, output measurement, technical da-

ta, warranty and servicing. For further de-

tails, please refer the separate holder/

operator manual of the engine manufactur-

er.

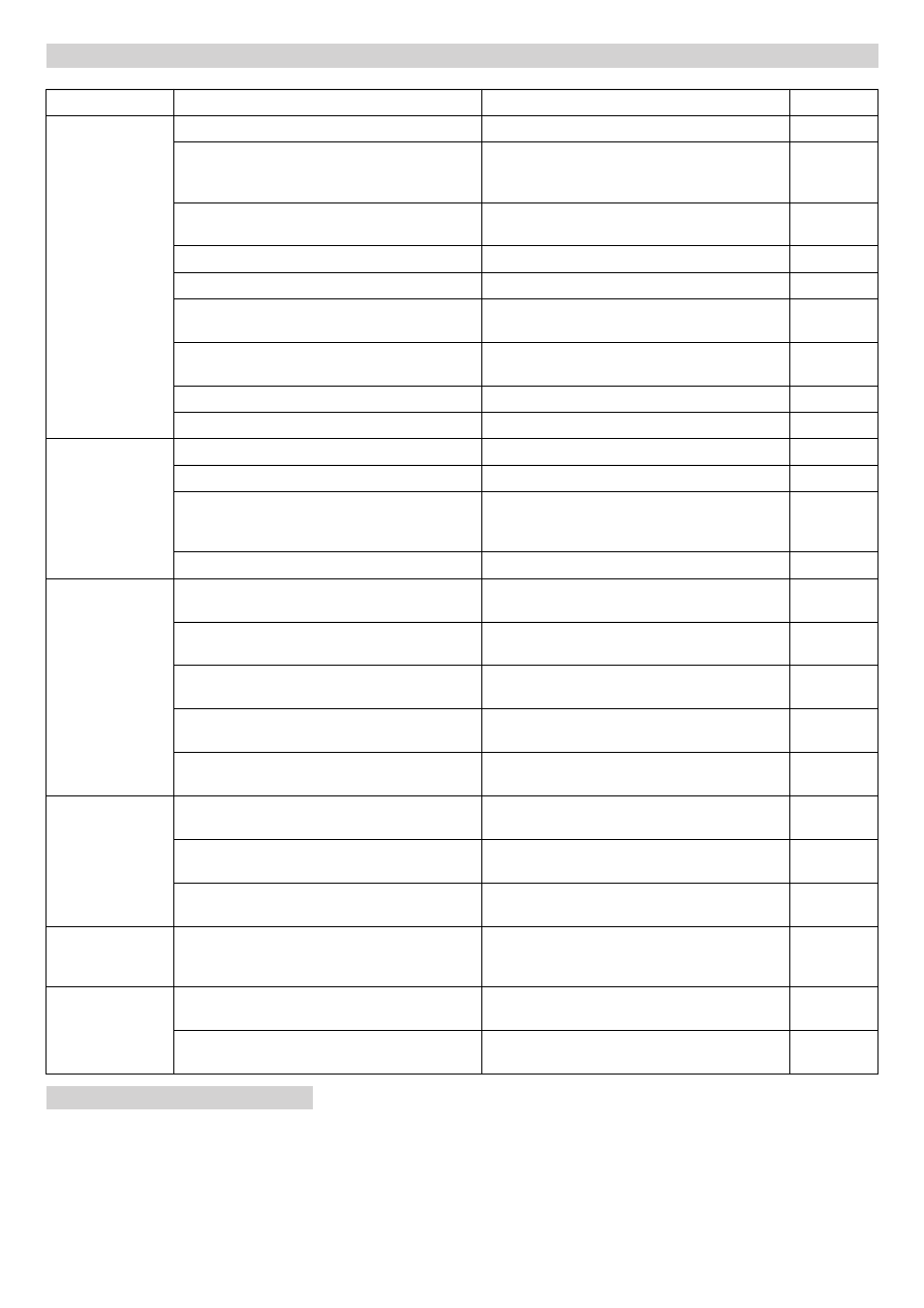

Troubleshooting

Fault

Possible cause

Remedy

of whom

Engine does not

start

Fuel tank empty.

Refill the fuel tank.

Operator

Fuel idling for a long time.

Remove the old fuel in a suitable container in the

open (See "Engine Instruction Booklet"). Fill up

the tank with clean, fresh fuel.

Operator

Engine in cold state; choke not set to "ON/

CHOKE".

Set the choke to "ON/CHOKE".

Operator

Gas lever no set to "fast".

Set the gas lever to "fast".

Operator

Ignition plug not inserted.

Insert the ignition plug into the spark plug.

Operator

Spark plug is dirty.

Clean the spark plug (see "Engine Instruction

Booklet").

Operator

Spark plug is defective.

Replace the spark plug.

Customer

Service

Carburetor is overflowing.

Set the choke to "RUN/OFF" and start.

Operator

Cold start help (Tupfer) not activated.

Use the cold start help (Tupfer).

Operator

Engine is running

erratically

Choke set to "ON/CHOKE".

Choke set to "RUN/OFF".

Operator

Ignition plug is loosely inserted.

Fix the spark-plug connector properly.

Operator

Fuel idling for a long time. Water or dirt in the fuel

system.

Remove the old fuel in a suitable container in the

open (See "Engine Instruction Booklet"). Fill up

the tank with clean, fresh fuel.

Operator

Ventilation hole in tank lid blocked.

Clean tank lid and ventilation hole.

Operator

Machine does not

clear snow

Shearing bolts torn off.

Replace shearing bolts (see "Replacing shear-

ing bolts").

Operator

Snail or discharge shaft is blocked.

Stop the engine, pull out the ignition plug. Re-

move the blockage.

Operator

Clutch tension for snail drive is not set properly. Set clutch tension (see "Setting clutch for snail

drive").

Operator

V-belt loose.

Tighten V-Belt.

Customer

Service

V-belt torn.

Replace V-belt.

Customer

Service

Machine does not

move

Clutch tension for travel drive is not set properly. Adjust clutch tension (see "Setting the clutch for

travel drive").

Operator

V-Belt is loose or torn.

Tighten the loose V-Belt. Replace torn V-Belt.

Customer

Service

Friction wheel rubber is torn.

Replace friction wheel rubber.

Customer

Service

Excessive vibra-

tion

Loose parts or damaged snail.

Stop the engine immediately, pull out the ignition

plug. Tighten loose screws and nuts. Repair

damaged snail.

Customer

Service

Gears can be

switched with

great difficulty

Clutch tension for travel drive is not set properly. Adjust clutch tension (see "Setting the clutch for

travel drive").

Operator

Switching lever not adjusted properly.

Check switching lever (see "Setting the switch-

ing lever").

Operator

Information about engine

17

EN