Vertical contact toaster – A.J. Antunes & Co VCT-20 9200552 User Manual

Page 18

18

VERTICAL CONTACT TOASTER

P/N 1010719 Rev. E 02/13

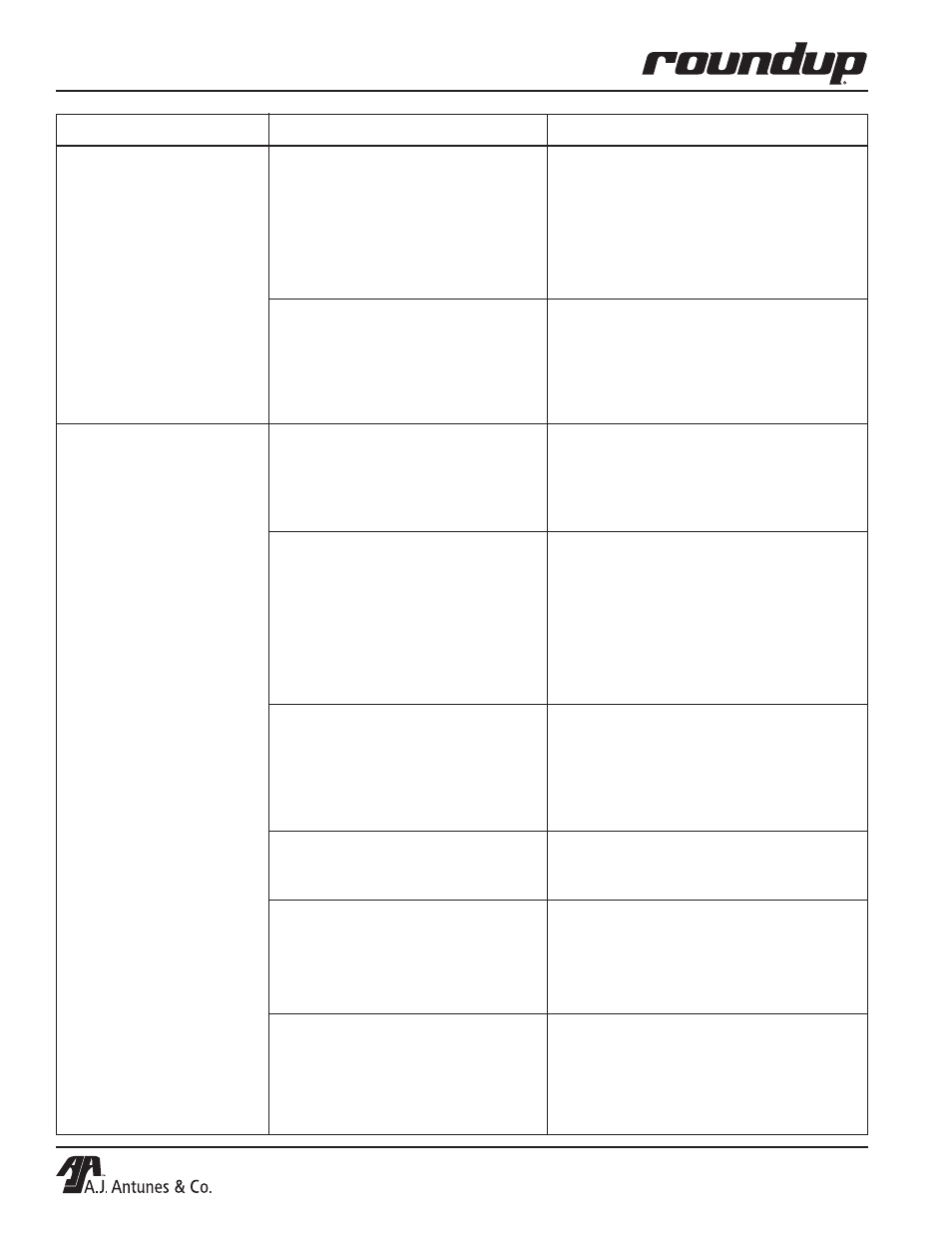

No heat and conveyor belts

move (continued).

Platen is hot and conveyor

belts do not move.

Inoperative temperature display

control or platen (continued).

Ambient temperature in control

compartment too high.

Wiring problems.

Drive motor inoperable or incorrect

conveyor drive motor.

Broken drive chain or loose sprocket.

Conveyor belts installed incorrectly.

Conveyor interlock switch not

depressed or faulty.

Roller tensioner assy. bent or missing.

Conveyor belts too loose (excessive

slack).

To check platen:

Use an Ohm meter to test resistance of the

platen heater (disconnect 1 wire to isolate

heater). Correct cold resistance for heating

element of platen is 17.81 Ohms at

208V/2550 Watts. The auxiliary heaters are

108.2 Ohms at 208V/400 Watts.

“CHEC” is showing in temperature display.

Turn toaster off and allow control compart-

ment to cool down to 140°F (60°C) and

restart toaster. Be sure cooling fan is oper-

ating and nothing is blocking the flow of

cooling air to bottom of toaster.

Check all electrical connections for burns,

discoloration or arcing. Replace all connec-

tions or components with damaged termi-

nals. Replace all damaged wiring with the

same (or higher) rated wire.

To check drive motor:

1. Measure resistance of motor coil.

Replace motor if coil measures either

open circuit or zero resistance.

2. Mark the drive motor sprocket and count

the turns per minute. Correct drive motor

speed is

nine (9) turns per minute.

Check drive chain for kinks, broken or bent

links or other damage. Check motor

sprocket and drive sprockets (on drive

shaft); tighten setscrew on flat of shaft if

required. Check for damaged/worn sprock-

ets and replace as required.

Install conveyor belt to match diagram in

Fig. 17 (page 13). Be sure that ends of the

hooks are facing down.

Install heat shield correctly or replace

switch.

Replace roller tensioner assy(s). (29, page

26).

See Servicing Conveyor Belts (page 13).

Problem

Possible Cause

Corrective Action