ROTHENBERGER ROWELD P250-630 B Plus Premium CNC User Manual

Page 44

ENGLISH

42

The upper progress bar shows whether the pressure lies within the correct range (green) or

within a permissible (yellow) tolerance range or whether it lies outside (red) the tolerance

range. The time lapse is shown below. The actual pressure is shown in display (2) and the

remaining joining time in display (9).

The pressure is automatically monitored and regulated. If the hydraulic system repumps too

often (meaning there is high pressure loss), have it checked.

Put the heating element back in the storage case.

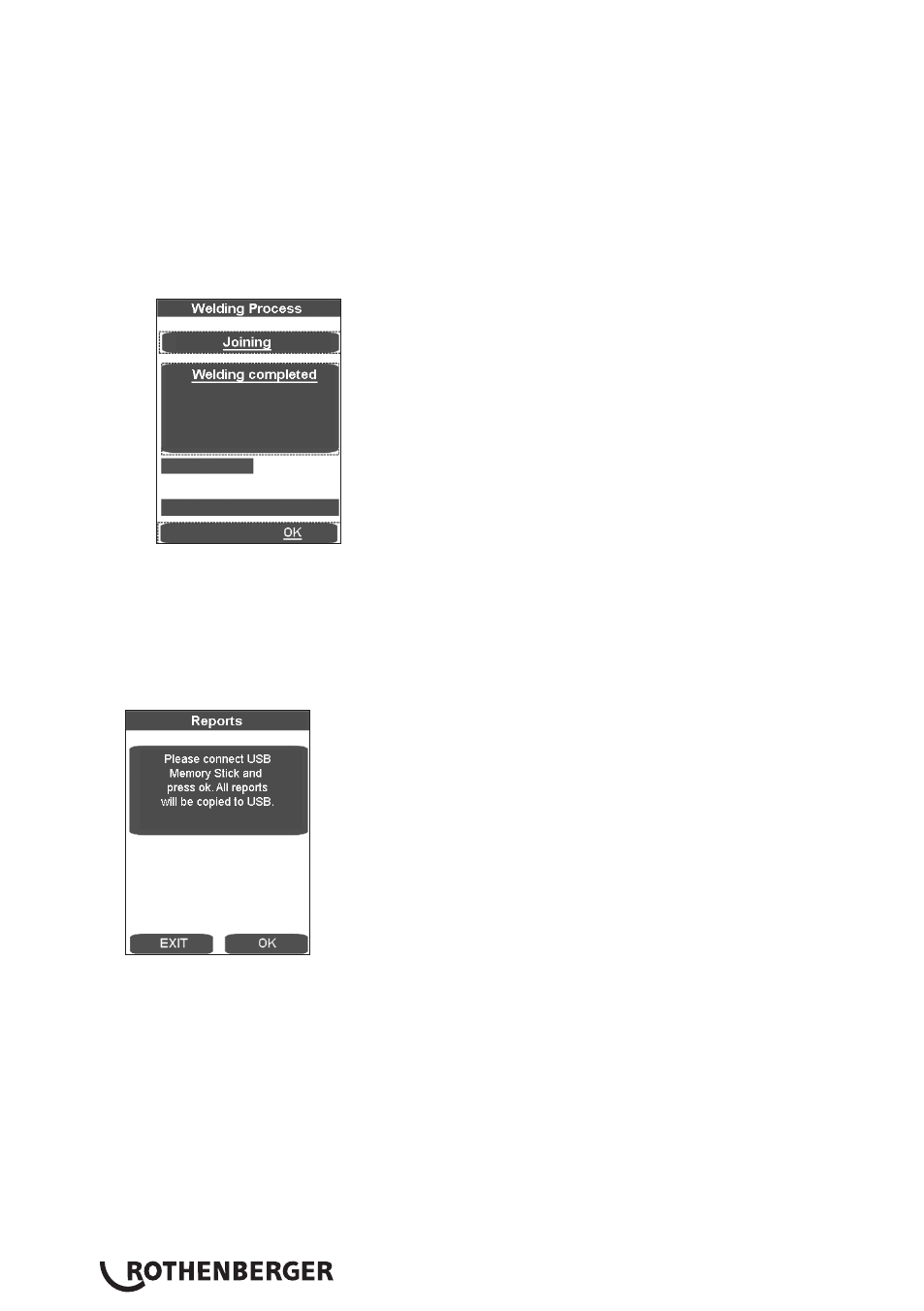

The welding process is ended after the cooling down time has expired, is stored, a signal

sounds and the pressure is dissipated automatically.

Conclude with use of the welding menu by pressing OK.

Dissipate the pressure completely by pressing the button (3).

Unclamp the welded work pieces and remove them.

Move the basic machine apart. The machine is ready for the next welding cycle.

Transferring the log:

In the Log menu item, these can be saved with OK, if a USB stick is connected. The window then

closes automatically.

This report file should be processed using the ROTHENBERGER Dataline 2 software and a

computer.

All welding parameters can be found in the enclosed welding tables.