Campbell Scientific 229 Water Matric Potential Sensor and CE4/CE8 User Manual

Page 7

229 Heat Dissipation Matric Water Potential Sensor

A change in the water potential and water content of the ceramic matr

a corresponding change in the thermal conductivity of the ceramic/water

complex. As the water content in the ceramic increases, the thermal

conductivity of the complex also increases. At very low water contents, th

ceramic material controls the thermal conductivity. As water content in t

ceramic increases, water films are established between the solid particles

resulting in a rapid increase in thermal conductivity. As the pores in the

ceramic continue to fill, the thermal conductivity becomes

ix causes

e

he

,

increasingly

controlled by the continuous water and the increase in thermal conductivity of

ture

the

d by

gy

e

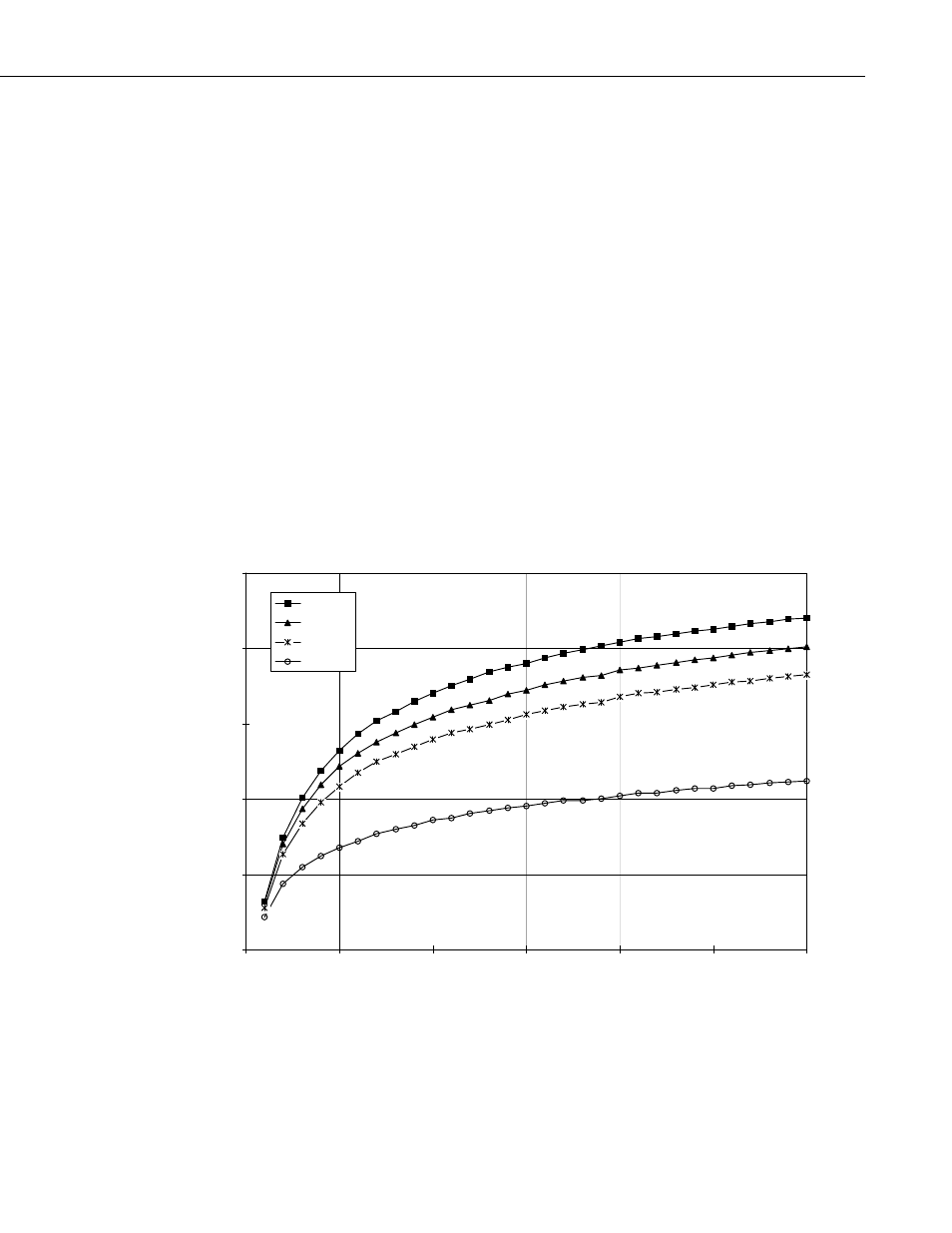

se ranges from

approximately 0.7ºC under wet conditions to 3.0ºC when dry. Figure 1-3

presents a typical temperature response in a silt loam.

the ceramic/water complex approaches a constant value.

When a constant power is dissipated from the line heat source, the tempera

increase near the heat source will depend on the thermal conductivity of

ceramic/water complex surrounding the heater. A temperature increase is

caused by heat that is not dissipated. As the water content and thermal

conductivity of the ceramic increases, the temperature increase as measure

the thermocouple will be reduced because conduction of the thermal ener

from the heat source is greater. A drier sensor will have a lower thermal

conductivity, so the thermal energy will not dissipate as quickly and th

temperature rise will be greater. When 50 milliamps is passed through the

heating element for 30 seconds, the temperature increa

0.5

1

1.5

2

2.5

3

0

5

10

15

20

25

30

200 kPa

100 kPa

50 kPa

heating time (s)

10 kPa

Temperature Response of 229 Sensor in Silt Loam Soil

tem

p

er

atu

re i

n

cr

eas

e (

C

)

FIGURE 1-3. Typical

3