0 accuracy: procedures/definitions, Typical calibration chart – Ashcroft 1036 Gauge with 1037 Fitting User Manual

Page 6

6

f.

Gauges showing significant friction error and/or wear of

the movement and linkage.

g.

Gauges having damaged sockets, especially damaged

threads.

h.

Liquid filled gauges showing loss of case fill.

NOTE: ASME B40.100 does not recommend moving gauges

from one application to another. This policy is prudent in that

it encourages the user to procure a new gauge, properly tai-

lored by specification, to each application that arises.

6.0 ACCURACY: PROCEDURES/DEFINITIONS

Accuracy inspection – Readings at approximately five

points equally spaced over the dial should be taken, both

upscale and downscale, before and after lightly rapping the

gauge to remove friction.

A pressure standard with accuracy

at least four times greater than the accuracy of the gauge

being tested is recommended.

Equipment – A finely regulated pressure supply will be required.

It is critical that the piping system associated with the test setup

be leaktight. The gauge under test should be positioned as it will

be in service to eliminate positional errors due to gravity.

Method – ASME B40.100 recommends that known pres-

sure (based on the reading from the pressure standard used)

be applied to the gauge under test. Readings including any

error from the nominal input pressure, are then taken from the

gauge under test. The practice of aligning the pointer of the

gauge under test with a dial graduation and then reading the

error from the master gauge (“reverse reading”) can result in

inconsistent and misleading data and should NOT be used.

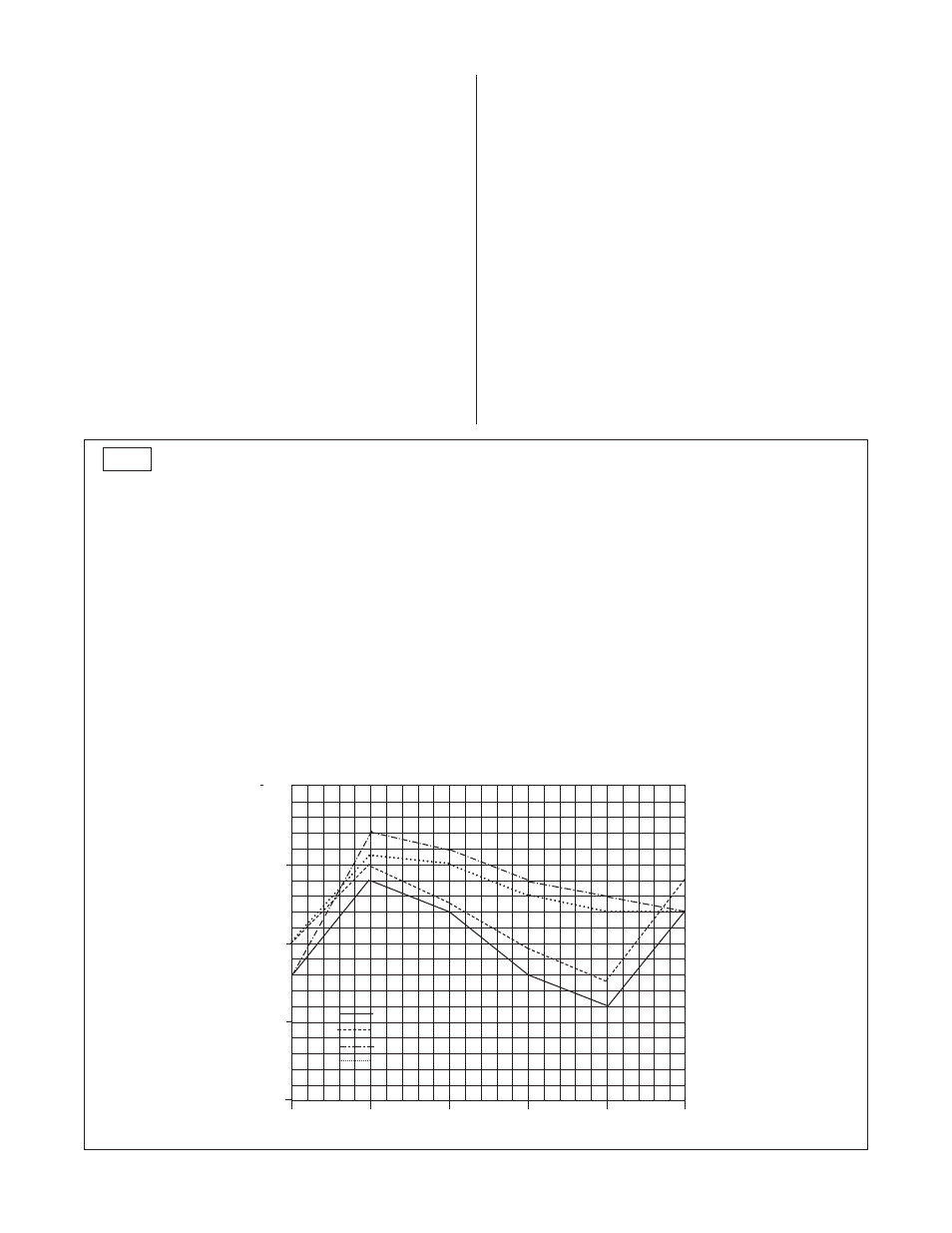

Calibration chart – After recording all of the readings it is

necessary to calculate the errors associated with each test

point using the following formula: ERROR in percent = 100

times (TRUE VALUE minus READING) ÷ RANGE. Plotting

the individual errors (Figure 1) makes it possible to visualize

the total gauge characteristic. The plot should contain all four

curves: upscale – before rap; upscale – after rap; downscale

– before rap; downscale – after rap. “Rap” means lightly tap-

ping the gauge

before reading to remove friction as

described in ASME B40.100.

Referring to Figure 1, several classes of error may be seen:

Zero – An error which is approximately equal over the entire

scale. This error can be manifested when either the gauge is

TYPICAL CALIBRATION CHART

INDICATED VALUE (PSI)

True Value –

Increasing –

Increasing –

Decreasing –

Decreasing –

PSI

Without RAP

With RAP

Without RAP

With RAP

0

–.4

0

–.4

0

40

+.8

+1.0

+1.4

+1.1

80

+.4

+.5

+1.2

+1.0

120

–.4

–1.0

+.8

+.6

160

–.8

–.5

+.6

+.4

200

+.4

+.8

+.4

+.4

ERROR (% OF FULL SCALE)

True Value –

Increasing –

Increasing –

Decreasing –

Decreasing –

% of Range

Without RAP

With RAP

Without RAP

With RAP

0

–.20

0

–.20

0

20

+.40

+.50

+.70

+.55

40

+.20

+.25

+.60

+.50

60

–.20

–.05

+.40

+.30

80

–.40

–.25

+.30

+.20

100

+.20

+.40

+.20

+.20

1.0

0.5

0.0

–0.5

–1.0

0

20

40

60

80

100

% of Range

◆

◆

◆

◆

■

■

■

■

●

●

●

●

●

●

▲

▲

▲

▲

▲

▲

▲ ▲

upscale – without rap

● ●

upscale – with rap

◆ ◆

downscale – without rap

■ ■

downscale – with rap

E

rr

o

r

(%

o

f

F

u

ll

S

c

a

le

)

FIG. 1

- 1009 - Stainless Steel Pressure Gauge 1008S/SL - Stainless Steel Pressure Gauge 1008S - Stainless Steel Pressure Gauge 1189 - Low Pressure Bellows Gauge 1188 - Low Pressure Bellows Gauge 1187 - Low Pressure Bellows Gauge 1150H - Reid Vapor Gauge 1122 - Industrial Gauge 1220 - Industrial Gauge 1017 - Industrial Gauge 1220 - Receiver Gauges 1017 - Receiver Gauges 1010 - Receiver Gauges 1009 - Receiver Gauges 1220 - Refrigeration Gauges 1017 - Refrigeration Gauges 1010 - Refrigeration Gauges 1009 - Refrigeration Gauges 1220 - Hydraulic Gauges 1017 - Hydraulic Gauges 1010 - Hydraulic Gauges 1009 - Hydraulic Gauges 1010 - Industrial Gauge 2462 - Duragauge® Pressure Gauge 1379 - Duragauge® Pressure Gauge 1377 - Duragauge® Pressure Gauge 2462 - Receiver Gauges 1377 - Receiver Gauges 1379 - Receiver Gauges 1279 - Receiver Gauges 1259 - Pressure Gauge 1082 - Pressure Test Gauge