Ashcroft, Type 1188 bellows gauge calibration procedure – Ashcroft 1036 Gauge with 1037 Fitting User Manual

Page 11

11

© Ashcroft Inc., 250 E. Main St., Stratford, CT 06614-5145, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale.

I&M008-

10173-3/10 (1188)

ASHCROFT

®

Type 1188 Bellows Gauge

Calibration Procedure

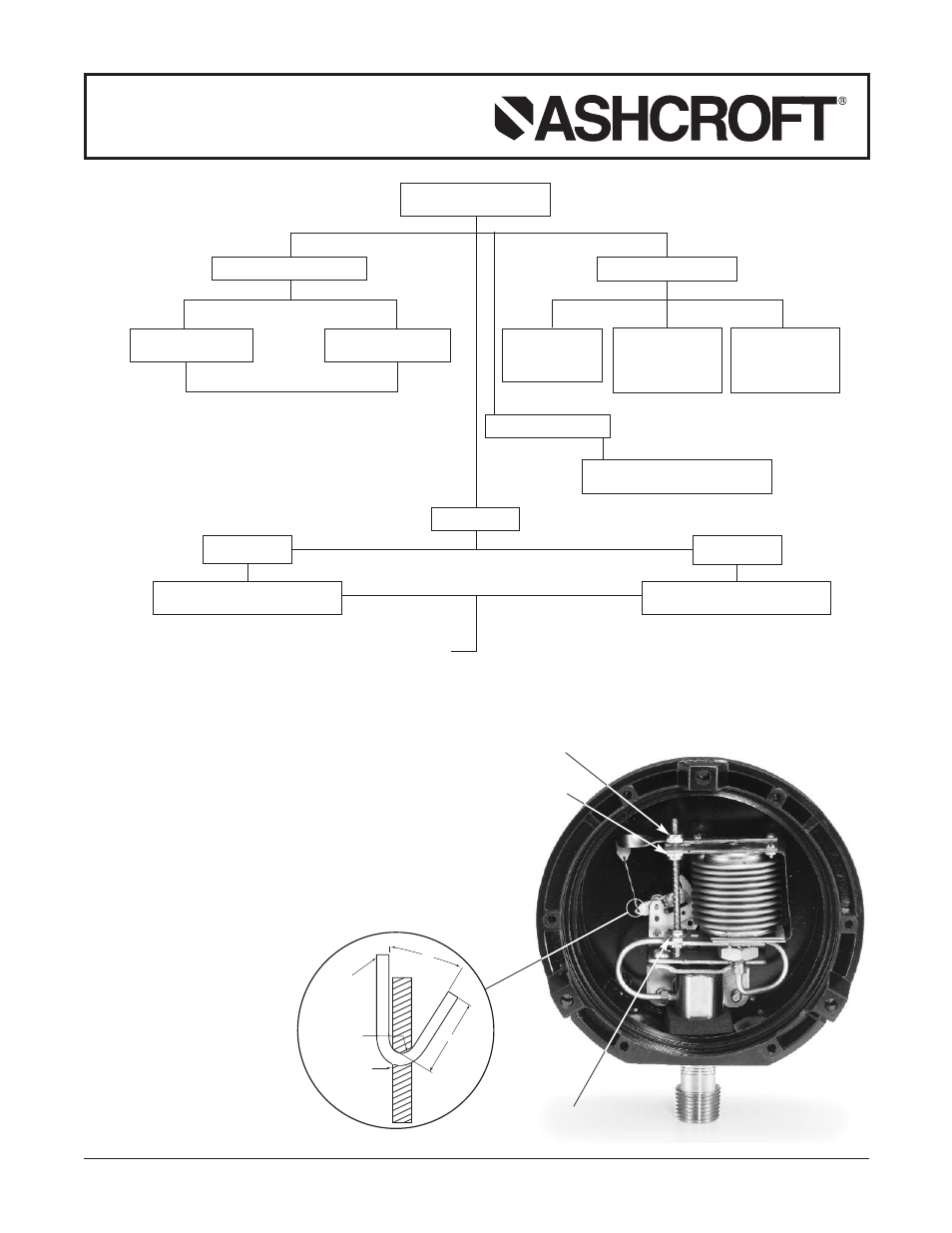

CALIBRATION & TROUBLE

CORRECTION DIAGRAM

POINTER JUMPING

SLUGGISH MOVEMENT

NON LINEAR

STICKY PARTS

Clean all bearings

and gear teeth

RANGE SPAN ADJUSTMENT

RANGE TOO SHORT

Adjust slide “S” inward

RANGE TOO LONG

Adjust slide “S” outward

LOOSE HAIRSPRING

Remove backlash by

disengaging pinion &

rotate to tighten

COUNTER BALANCE

RUBBING

Bend if necessary to

clear socket in travel

NOTE: After adjusting range span, set both movement stops.

Set the underload stop so that the pointer will stop at

zero. Set the overload stop so that the pointer will pass

the maximum range approximately 5˝.

NOTE:

After adjusting span re-zero pointer by removing from

pinion and re-assembling at the proper dial mark.

NOTE: To increase or decrease angle “A,“ bend tip inward or outward as

required. Doing this may run the movement segment off the pin-

ion. This can be corrected by cutting off one end off the link “E”

decreasing its length, or makin a new length from .032 dia. phos.

bronze wire.

Caution: When reproducing link end, follow figure 44 very closely.

this will prevent too much play, or, binding in operation.

REF: Replacing System Bellows

After assembling bellows to the gauge socket securely, subject sys-

tem to 30 psi for five minutes, allowing bellows to travel approxi-

mately 1/8˝ against the overload stop. After this, heat treat system for

15 hours at 250°F, this procedure is necssary to prevent gauge drift.

TIGHT HAIRSPRING

Loosen by disengaging pinion & rotate

NON LINEAR

FIRST 3RD.

NON LINEAR

LAST 3RD.

ADJ. ANGLE OF PULL

BY INCREASING ANGLE “A”

ADJ. ANGLE OF PULL

BY DECREASING ANGLE “A”

STOP LOCKING

SCREWS

OVERLOAD

STOP

SLIDE AND LINK (angle “A”)

Enlarged view of slide and link

UNDERLOAD

STOP

1/8

60°

.020 R

E

(LINK)

S

(SLIDE)

- 1009 - Stainless Steel Pressure Gauge 1008S/SL - Stainless Steel Pressure Gauge 1008S - Stainless Steel Pressure Gauge 1189 - Low Pressure Bellows Gauge 1188 - Low Pressure Bellows Gauge 1187 - Low Pressure Bellows Gauge 1150H - Reid Vapor Gauge 1122 - Industrial Gauge 1220 - Industrial Gauge 1017 - Industrial Gauge 1220 - Receiver Gauges 1017 - Receiver Gauges 1010 - Receiver Gauges 1009 - Receiver Gauges 1220 - Refrigeration Gauges 1017 - Refrigeration Gauges 1010 - Refrigeration Gauges 1009 - Refrigeration Gauges 1220 - Hydraulic Gauges 1017 - Hydraulic Gauges 1010 - Hydraulic Gauges 1009 - Hydraulic Gauges 1010 - Industrial Gauge 2462 - Duragauge® Pressure Gauge 1379 - Duragauge® Pressure Gauge 1377 - Duragauge® Pressure Gauge 2462 - Receiver Gauges 1377 - Receiver Gauges 1379 - Receiver Gauges 1279 - Receiver Gauges 1259 - Pressure Gauge 1082 - Pressure Test Gauge