Dake Dura Press Force - 10/20 User Manual

Page 14

Force 10M /Force 20M14

14

06/10

4.2 POSITIONING THE PRESS

Simple precautions are necessary for correctly positioning the press. Always

consider the safety aspect not only in relation to the work carried out with the press,

but also to the dangers originated by the other machines in the workplace. Before

positioning, check that

-

The floor is suitable for positioning the press that is it has no holes or

subsiding portions, and that its capacity is sufficient to sustain the

weight of the press plus the weight of the accessory parts and of any

piece to be processed if of large dimensions, considering an

appropriate coefficient of safety.

-

Do not do the positioning on unstable or non-compact surfaces

(e.g. on gravel or grit, beaten earth, sand, etc.).

-

PAY THE UTMOST ATTENTION TO OVERHEAD ELECTRICITY

LINES.

-

Check beforehand the position of any overhead electricity lines

and mark them with special warning cards.

-

Always consider a suitable distance from the sliding paths for the

means of transport, elevators, transpallets, etc., sudden and

unexpected sources of danger.

-

Check that the position identified is always served by adequate lifting

systems.

-

Pay the utmost attention to handling the lifting systems (e.g. overhead

traveling cranes, hoists, transpallets, fork-lift trucks, cranes, jib cranes,

etc.)

After identifying the most suitable place for positioning, follow the instructions for

handling of

Section 5.0

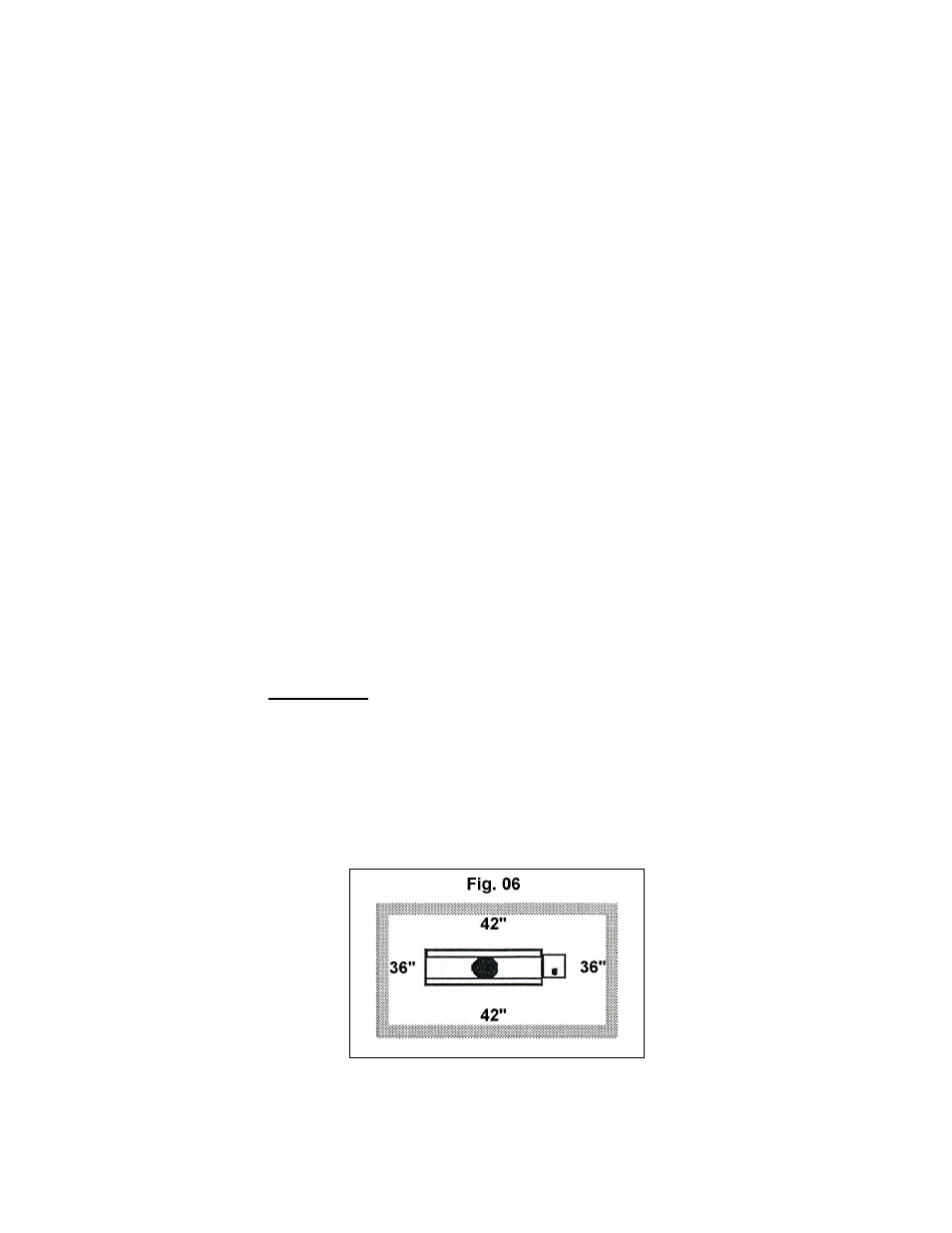

, mark a square on the floor with YELLOW paint (highly

resistant to abrasion) around the perimeter of the press as shown by the diagram

in Fig. 06.

The area highlighted in this way will indicate the area of caution for the lifting

equipment and the personnel nearby.