Application – Red Lion IAMA User Manual

Page 8

MODEL IAMA

OUTPUT

RANG

E

INPUT

RANG

E

20mA/1mA OUTPUT

IN FIE

LD/FACT

.

OUT FIELD/FACT

.

7

ON

1

6

5

4

3

2

10

9

8

IAMA

S

T

A

T

U

S

IAMA

A

S

T

T

U

S

MO

DEL

IA

MA

ON

10

9

20mA/1mA OUTP

UT

INPUT RANG

E

1

5

4

3

2

7

6

8

OUTPUT R

AN

GE

IN F

IELD/FACT.

OUT FI

ELD/FA

CT.

20mA

/1mA OUTPUT

U

T

T

S

A

IAMA

ON

OUT FI

ELD/FACT

.

IN FIE

LD/FACT

.

OUTPUT R

ANG

E

8

6

7

2

3

4

5

1

INPUT RA

NG

E

9

10

MO

DEL

IA

MA

S

20mA/1mA O

UTP

UT

U

T

T

S

A

IAMA

ON

OUT FIELD/

FACT

.

IN FIELD/FACT

.

OUT

PU

T RANG

E

8

6

7

2

3

4

5

1

INPU

T RANG

E

9

10

MO

DEL

IA

MA

S

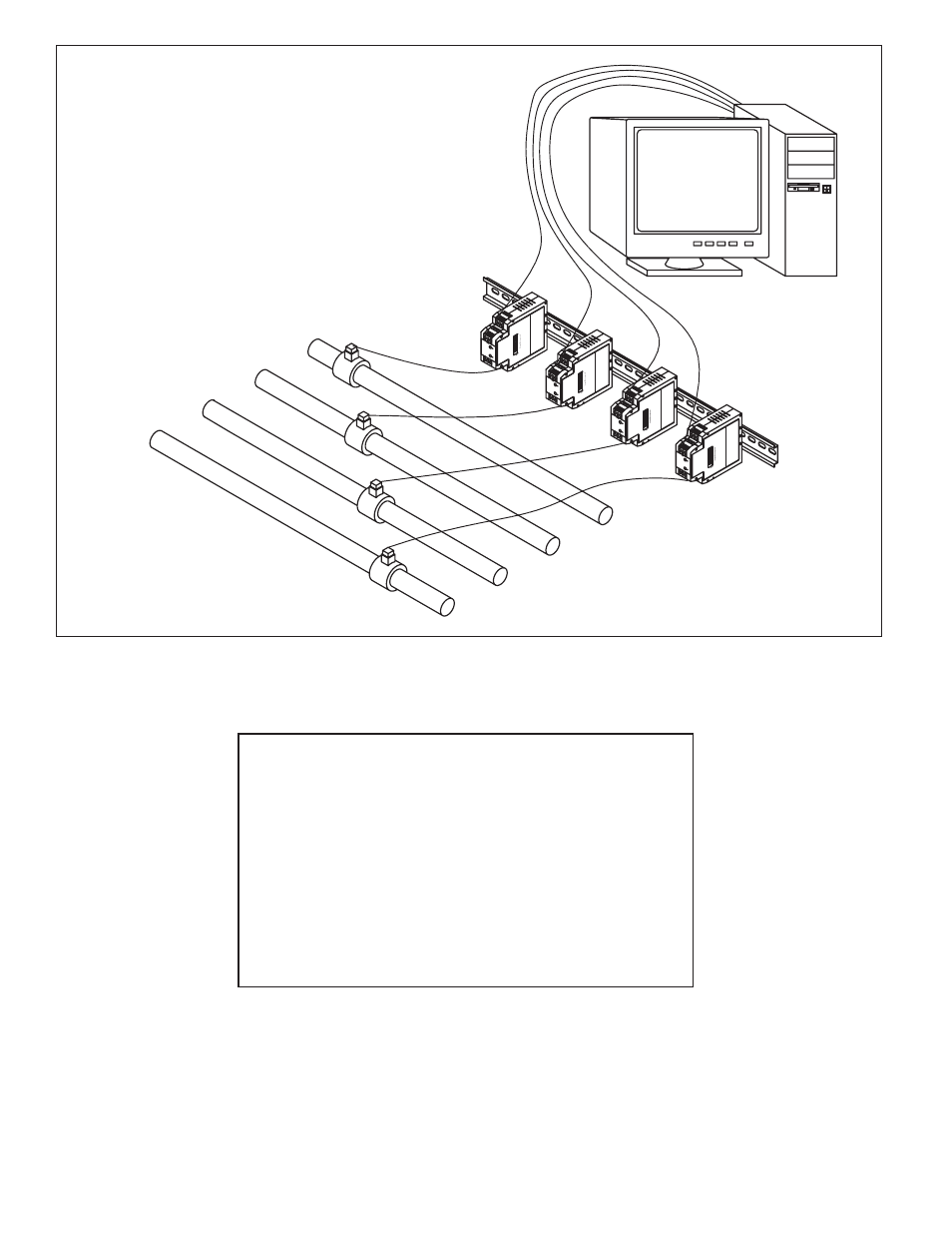

APPLICATION

Cost efficiency measurements of a printing company included the

reduction of bulk stock of the various inks used in their printing processes.

The company currently had various ink flow and level devices with different

current and voltage outputs and wanted to record these measurements into a

control room PC. Several IAMA Universal Signal Conditioning Modules

were the answer. The IAMA’s universal input allowed for easy signal

conditioning of the various output signals to the required PC’s Bus Board 0

to 10 VDC input signal. The factory calibration settings of the IAMA could

be used with the devices in which the flow and level pressure was linear to

the signal. The IAMA could also be scaled utilizing the field calibration

method with the devices where pressure affected the signal slope

specifications. In this case, the IAMA’s re-transmitted 0 to 10 VDC output

was field calibrated, negating the expense and time required to rewrite the

PC’s software parameters. In addition to accepting multiple signal types and

field calibration features, the IAMA also provides the necessary electrical

isolation between the control room PC and the hazards of the printing floor

electrical noise.

LIMITED WARRANTY

The Company warrants the products it manufactures against defects in materials and workmanship

for a period limited to two years from the date of shipment, provided the products have been stored,

handled, installed, and used under proper conditions. The Company’s liability under this limited

warranty shall extend only to the repair or replacement of a defective product, at The Company’s

option. The Company disclaims all liability for any affirmation, promise or representation with

respect to the products.

The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against

damages, claims, and expenses arising out of subsequent sales of RLC products or products

containing components manufactured by RLC and based upon personal injuries, deaths, property

damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be

to any extent liable, including without limitation penalties imposed by the Consumer Product Safety

Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty

Act (P.L. 93-637), as now in effect or as amended hereafter.

No warranties expressed or implied are created with respect to The Company’s products except

those expressly contained herein. The Customer acknowledges the disclaimers and limitations

contained herein and relies on no other warranties or affirmations.

Red Lion Controls

Headquarters

20 Willow Springs Circle

York PA 17406

Tel +1 (717) 767-6511

Fax +1 (717) 764-0839

Red Lion Controls

China

Unit 302, XinAn Plaza

Building 13, No.99 Tianzhou Road

ShangHai, P.R. China 200223

Tel +86 21 6113 3688

Fax +86 21 6113 3683

Red Lion Controls

Europe

Softwareweg 9

NL - 3821 BN Amersfoort

Tel +31 (0) 334 723 225

Fax +31 (0) 334 893 793

Red Lion Controls

India

201-B, 2nd Floor, Park Centra

Opp 32 Mile Stone, Sector-30

Gurgaon-122002 Haryana, India

Tel +91 984 487 0503