Module isolation, Overview, Inputs – Red Lion IAMA User Manual

Page 2: Outputs, Zero and span, Illegal range selections and changes, Checksum errors

2

13. ACCURACY (INCLUDING LINEARITY): Factory: ±0.1% of span

max. for all ranges except 1 mA, 2 mA, and 20 mV. These ranges are

accurate to ±0.2% of span max. All ranges can be field calibrated to 0.1%

of span max.

14. RESOLUTION: 0.01% full scale input, 0.01% full scale output

15. ENVIRONMENTAL CONDITIONS:

Operating Temperature Range: -20 to +65 °C

Storage Temperature Range: -40 to +85 °C

Operating and Storage Humidity: 85% max. relative humidity (non-

condensing) from -20 to +65 °C

Temperature Coefficient: ± 0.01%/°C (100 PPM/°C) max.

Vibration to IEC 68-2-6: Operational 5 to 150 Hz, 2 g.

Shock to IEC 68-2-27: Operational 30 g

Altitude: Up to 2000 meters

16. CERTIFICATIONS AND COMPLIANCES:

CE Approved

EN 61326-1 Immunity to Industrial Locations

Emission CISPR 11 Class A

IEC/EN 61010-1

UL Recognized Component: File #E179259

Refer to EMC Installation Guidelines section of this bulletin for additional

information.

17. CONSTRUCTION: Case body is black high impact plastic

18. CONNECTIONS: 14 AWG max

19. MOUNTING: Standard DIN top hat (T) profile rail according to EN50022

- 35x7.5 and 35 x 15 and G profile rail according to EN50035-G32.

20. WEIGHT: 4.5 oz. (127.57 g)

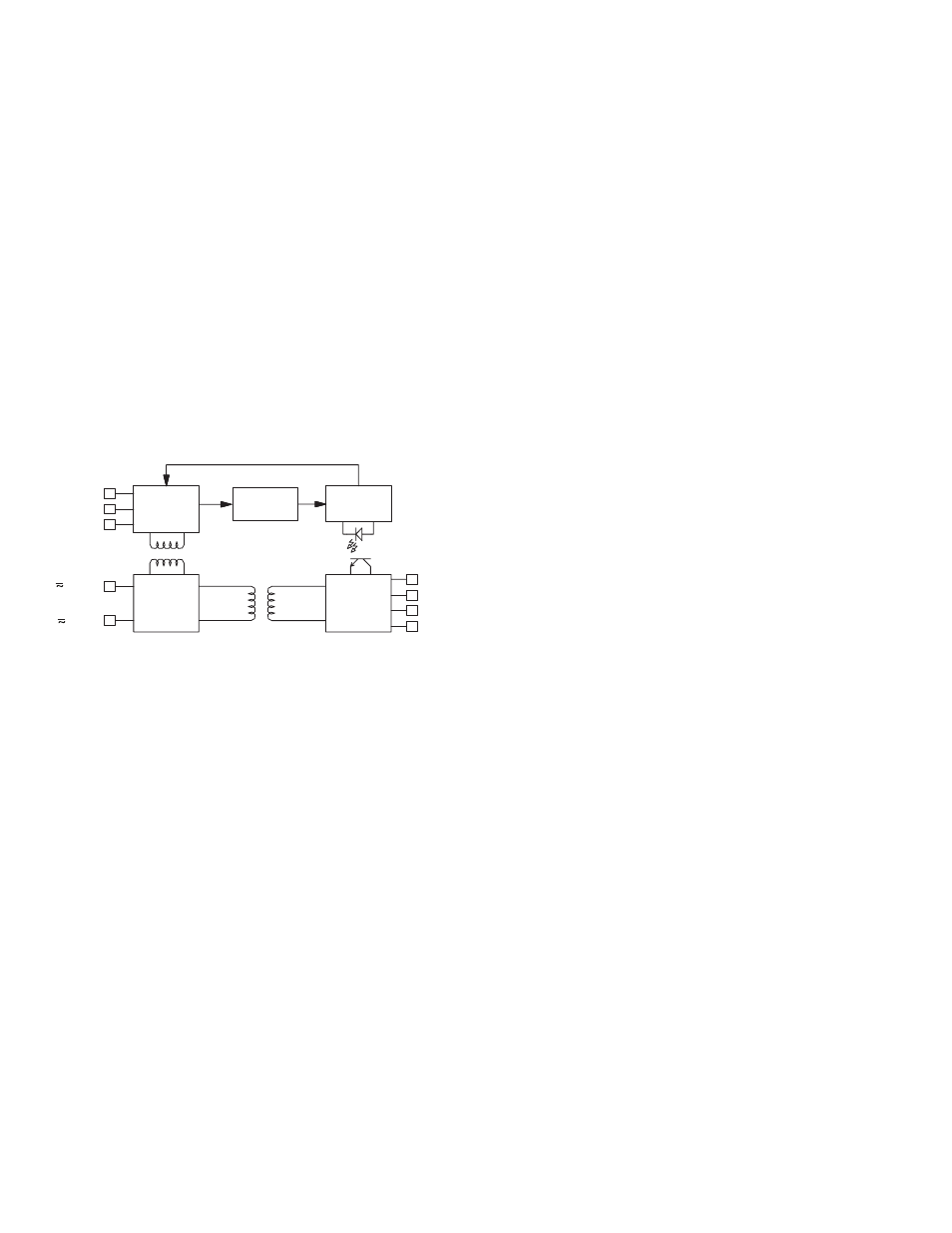

MODULE ISOLATION

IAMA modules feature “3-Way” Signal Isolation. The 3-Way isolation is a

combination of optical and transformer isolation. The optical isolation provides

common mode voltage (CMV) isolation up to 1.5 kV between the sensor input

and the process signal output. The IAMA’s power is isolated from the sensor

signal input and the process signal output by a DC/DC transformer isolation

circuit.

OVERVIEW

The IAMA3535 continuously monitors a voltage or current input and

provides a linearly proportional voltage or current output, while the IAMA6262

transmits the scaled square root of the input signal. This allows the IAMA6262

to provide a signal that is linear to flow rate in applications utilizing a

differential pressure transducer. Both units have two modes of operation known

as Factory and Field modes. Factory mode is used when the default input and

output ranges are suitable. Field mode can be independently selected for both

the input and output, and allows the user to custom calibrate, or scale the signal.

If Factory mode is selected, the IAMAs use factory presets for the selected input

or output range. If Field mode is selected, the IAMAs can be custom scaled

within a selected input or output range. Field mode also allows the IAMA to

reverse its output in relation to its input.

The units are factory precalibrated for minimum and full scale for all input

and output ranges. The factory calibration values are permanently stored in

E

2

PROM and should not be changed in the field, unless unacceptable error or a

factory checksum error occurs. See Factory Recalibration for details. Field

scaling is achieved by applying minimum and full scale values from a

calibration source and storing the values by a single DIP switch transition. Field

scaling is available for all input and output ranges and the values are

permanently stored in E

2

PROM until reprogramming occurs.

After field scaling, the IAMAs can be changed between Factory and Field

modes for a particular range, which restores the respective setting. The Factory

and Field E

2

PROM locations contain the same calibration values when the

IAMA is received from the factory. Therefore, until the IAMA is field scaled,

factory and field modes perform identically. See SCALING PROCEDURE for

detailed instructions on field programming the IAMA.

The units can be scaled to any minimum scale and full scale values within the

extent of the selected range. The closer together the minimum and full scale

values are to each other, the less accurate the signal will be. For example, if the

0 to 1 V input range is selected, and the unit is scaled for 0 to 0.5 V, the signal

has the same resolution as the 0 to 1 V range. Since this resolution will be two

times the percentage of span for 0.5 V, more accuracy can be achieved by using

the 0 to 0.5 V range.

The input may exceed the full scale value for the selected range by 10% of

span, but the IAMA will not update the output beyond 10% over range.

The red and green LED’s indicate the status of the modules during scaling and

normal operation. Table 1, LED Indications, details the LED indications for

various unit conditions.

The IAMA – Signal Conditioning Module Series is designed for use in

industrial environments. Suppressor diodes protect both input and output

circuits from wiring errors and transient high voltage conditions.

INPUTS

The IAMAs accept a full range of process signal inputs and isolate and

convert these signals to common industrial control signals. The input signal

combinations are configured by making specific DIP switch selections on the 10

position DIP switch.

OUTPUTS

As with the input choices, the process signal output of the modules is DIP

switch selectable. A 1 position DIP switch is used to select between the 1 mA/20

mA output ranges. The maximum output current signal is 22 mA with ≤600 Ω

output resistance and the maximum output voltage signal is 11 V with ≥1 KΩ

output resistance.

ZERO AND SPAN

The input zero and span are set by first applying the minimum value then

transitioning S1-2 to store that value. Next, the full scale value is applied and the

DIP switch transition stores the value. The output scaling is performed in a

similar manner but the output is driven to the desired minimum and full scale

values by the calibration source applied to the input. S1-1 is used to store the

minimum and full scale output values.

The span is defined by: span = (full scale - minimum scale).

ILLEGAL RANGE SELECTIONS AND CHANGES

The ranges should only be selected before power is applied. If an invalid input

or output range is selected when power is applied the output is set to approximately

0 VDC and the red LED indicates the error according to Table 1. Power must be

removed and valid ranges selected for the IAMA to operate properly.

If S1 switches 3 through 10 are changed while the IAMA is operating, the red

LED indicates a range change according to Table 1, LED Indications and the

output goes to the previously stored range minimum scale value. Normal

operation will be resumed if the switches are placed back in the previous

positions or power is removed and restored.

CHECKSUM ERRORS

A checksum is performed every time power is applied to the IAMA. If a

checksum error occurs, the LEDs will indicate where the error occurred

according to Table 1, LED Indications. Operation with a checksum error is not

recommended but can be done in critical situations. If an error occurs,

re-calibration of the field or factory ranges to be used must be performed.

If a field checksum error occurs, the IAMA will operate only in factory mode.

If a factory checksum occurs, the IAMA will operate only in a previously

calibrated field mode. Do not perform a field scaling until the factory checksum is

cleared. Since a checksum error is a high priority LED indication, the LEDs will

indicate the error until it is cleared. This will exclude other LED information.

*

10

12

VARIABLE

GAIN

AMP

V/F

CONVERTER

PROCESS

CIRCUITY

6

5

1

4

PWM

CIRCUITRY

V

V

I

I

3

2

POWER

SUPPLY

V

I

INPUT

COMMON

IN

IN

OUT+

OUT-

OUT+

OUT-

DC- (AC)

DC+ (AC)

BLOCK DIAGRAM

*

Terminal number is dependent on max. input voltage.