Output features, Auto-tune, Profile programming – Red Lion TSC User Manual

Page 5: Controller programming, Hidden functions mode, Output variations without rs485 option, Output variations with rs485 option, Unprotected parameter mode, Protected parameter mode

5

OUTPUT FEATURES

Programmable output power limits provide protection for processes where

too much power can cause damage. Automatic sensor probe break detection, for

fail-safe operation, causes the controller to default to a programmed output

power (upscale or downscale burnout). With adjustable time proportioning-

cycle time and programmable D.C. Linear output, the controller can satisfy a

wide variety of output requirements.

During execution of a profile, two independent, timed event outputs are

available to control or signal other equipment. The event outputs use the alarm

channels.

The RS485 Communication option allows the user to access various

controller parameters such as the setpoint, % output power, % proportional

band, etc. The controller may be setup to transmit various parameters at a

programmable automatic print rate.

AUTO-TUNE

The model TSC has an auto-tune feature which, on demand, automatically

determines the PID control parameters for a particular thermal process. After

completion of auto-tune, the PID parameters are automatically optimized for

that process and loaded into nonvolatile memory. The operator may view and

modify the parameters as desired.

Auto-tune may be invoked at start-up, while ramping, or at setpoint,

depending on the process requirements. A programmable auto-tune damping

factor produces various levels of process control and response characteristics.

PROFILE PROGRAMMING

Profiles are programmed independently of each other and are separate from

the configuration of other controller parameters. Each profile has parameters for

error band (profile conformity), linking, auto-start and program repeat cycles.

Profiles may be altered during execution, so changes take effect as the

programmed profile advances.

CONTROLLER PROGRAMMING

The model TSC has been designed to reduce the operator interaction with the

controller while still maintaining a high degree of control accuracy and user

flexibility. Front panel program disable allows all of the controller’s set-ups to be

locked-out from further operator intervention after the initial parameter set-up.

The programming of the controller is divided into four sections:

Hidden Mode

Protected Mode

Unprotected Mode

Configuration Mode

These four programming modes allow the controller to adapt to any required

user-interface level.

UNPROTECTED PARAMETER MODE

The unprotected mode is accessible when program disable is inactive or when

the proper access code number from the protected mode is entered. Only from

this mode can the configuration modes be accessed.

“SP”

- Enter setpoint

*

“OPOF”

- Enter %output power offset

*

“OP”

- Enter output power

*

“ProP”

- Enter proportional band

“Intt”

- Enter integral time

*

“dErt”

- Enter derivative time

*

“AL-1”

- Enter value for alarm #1

*

“AL-2”

- Enter value for alarm #2

*

“CNFP”

- Select basic configuration module

“End”

- Return to normal display mode

PROTECTED PARAMETER MODE *

The protected mode is accessible when program disable is active, also this

mode prevents access to the configuration modes without the proper access code

number. Only the parameters that are selected in the configuration 3 parameter

lock-outs section can be accessed.

“ProP”

- Enter proportional band

“Intt”

- Enter integral time

“dErt”

- Enter derivative time

“AL-1”

- Enter value for alarm #1

“AL-2”

- Enter value for alarm #2

“CodE”

- Enter access value to unprotected mode

“End”

- Return to normal display mode

HIDDEN FUNCTIONS MODE

*

The hidden mode is accessible from the normal operating mode by holding

the PAR button for 3 seconds. The five functions in this mode may be locked-out

individually in configuration 3 parameter lock-outs section.

“ CP”

- Load control point x

“Prun”

- Control ramp/hold profile state

“trnF”

- Transfer between automatic (PID) control

and Manual control

“tUNE”

- Invoke/Cancel PID auto-tune

“ALrS”

- Reset latched alarms

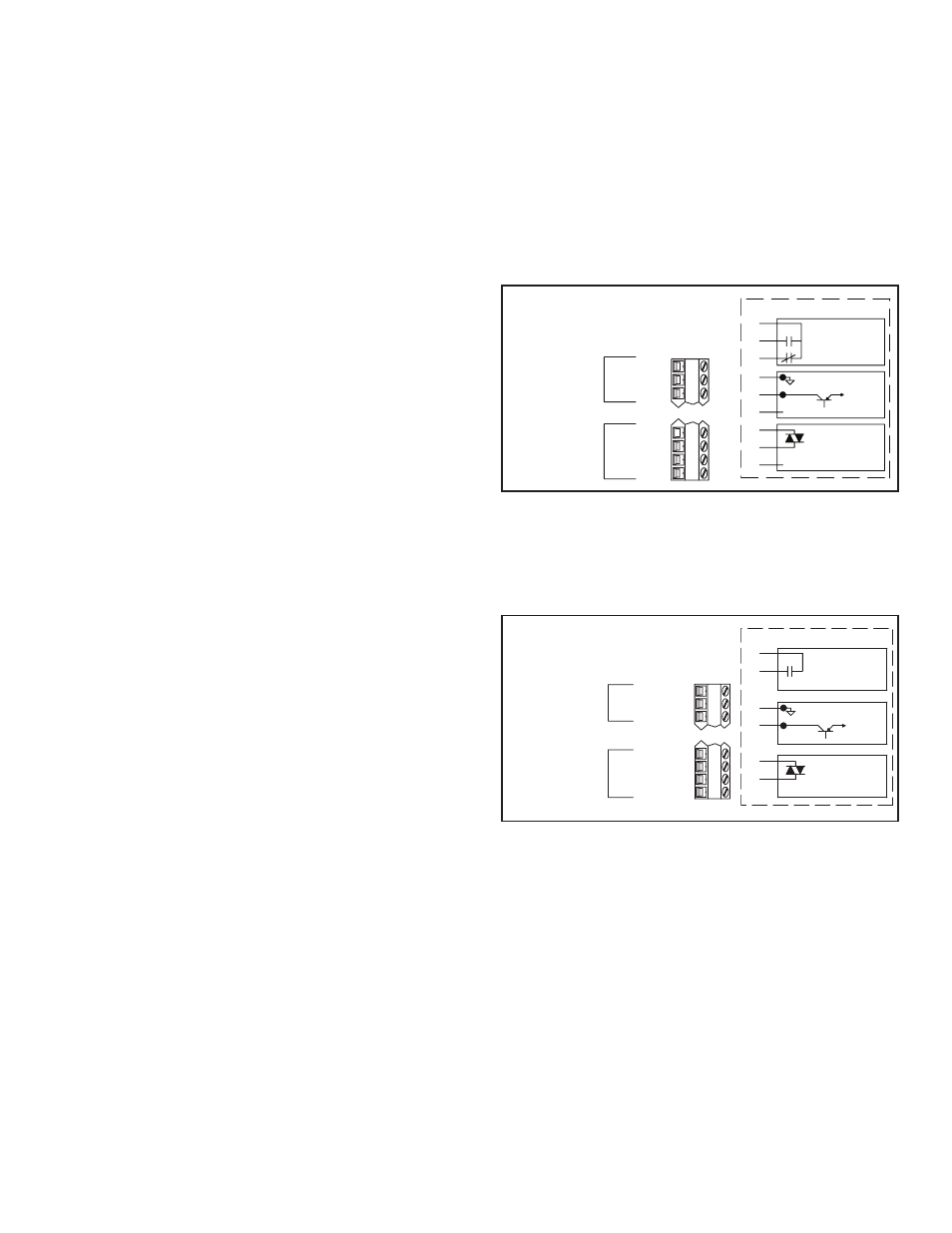

OUTPUT VARIATIONS WITHOUT RS485 OPTION

The Dual Alarm or the Cooling with Alarm output, without the RS485 option,

has independent outputs. Therefore, the cooling output and/or alarm output(s)

can be installed with any combination of output modules.

OUTPUT VARIATIONS WITH RS485 OPTION

The Dual Alarm or the Cooling with Alarm output, with RS485 option, does

not have independent outputs. In this case, the cooling output and/or alarm

output(s) must have the same type of output modules installed since they share

the common terminal.

*

These parameters may not appear due to option configuration or other

programming

3

2

1

AL2/OP2-C

AL2/OP2-B

AL2/OP2-A

OPTION

COOLING

OUTPUT 2

ALARM 2 OR

16

15

14

13

AL1-C

AL1-B

AL1-A

N/C

OPTION

ALARM 1

DUAL ALARM OR

COOLING W/ALARM OPTION

WITHOUT RS-485 OPTION

ALARM 1 AND ALARM 2

3

2

1

AL1-B

AL2/OP2-B

AL/OP2 COMM.-A

OPTION

COOLING

ALARM 1 WITH

OR

16

15

14

13

RS-485 COMM.

TX EN.

TX/RX(-)

TX/RX(+)

OPTION

RS-485

DUAL ALARM OR

COOLING W/ALARM OPTION

WITH RS-485 OPTION

C

B

A

DO NOT CONNECT

TRIAC

(ISOLATED)

1A @ 240VAC

LOGIC/SSR DRIVE

DO NOT CONNECT

+

-

(RESISTIVE LOAD)

5A @ 240VAC

RELAY

A

B

C

C

B

A

OUTPUT MODULES

+12VDC

NOT

ISOLATED

OUTPUT MODULES

A

B

B

A

RELAY

5A @ 240VAC

(RESISTIVE LOAD)

1A @ 240VAC

(ISOLATED)

TRIAC

A

B

ISOLATED

NOT

+12VDC

-

+

LOGIC/SSR DRIVE