Configuration mode, Hardware features, Setpoint features – Red Lion TSC User Manual

Page 4: Input features

4

CONFIGURATION MODE

The configuration modules serve to provide the basic set-ups required by

the controller. It is divided into sections which group together related

programming steps, such as inputs, outputs, alarms, etc. Upon completion of

each section, the program returns to the configuration selection stage, which

allows the user to return to the normal display mode, or advance to a later

configuration stage.

Configuration 1, Inputs

“tYPE”

- Select input probe type

“SCAL”

- Select temperature scale

“dCPt”

- Select temperature resolution

“FLtr”

- Select degree of input filtering

“SPAN”

- Enter input correction span (slope)

“SHFt”

- Enter input correction shift (offset)

“SPLO”

- Enter setpoint lower limit

“SPHI”

- Enter setpoint higher limit

“SPrP”

- Enter setpoint ramp rate

“InPt”

- Select user input function

Configuration 2, Outputs

“CYCt”

- Enter time proportioning cycle time

“OPAC”

- Select control action

“OPLO”

- Enter output power low limit

“OPHI”

- Enter output power high limit

“OPFL”

- Enter probe fail power preset

“CHYS”

- Enter ON/OF control hysteresis

“tcod”

- Select auto-tuning damping

“ANAS”

- Select linear DC output assignment

*

“ANLO”

- Enter linear DC low scaling value

*

“ANHI”

- Enter linear DC high scaling value

*

Configuration 3, Parameter lock-outs

“SP”

- Select degree of setpoint access

“OP”

- Select degree of power access

“P-CS”

- Select degree of profile status

access

“P-tr”

- Select degree of phase time remaining

access

“UdSP”

- Enable temperature units display

“CodE”

- Enter parameter access code

“PId”

- Select degree of PID access

“AL”

- Select degree of alarm access

*

“ALrS”

- Enable manual reset of alarms

*

“CPAC”

- Enable control point access

“PrAC”

- Enable ramp/hold program access

“trnF”

- Enable automatic/manual transfer

“tUNE”

- Enable auto-tune invocation

Configuration 4, Alarms

*

“Act 1”

- Select operation mode of alarm #1

“rSt1”

- Select reset mode of alarm #1

“Stb1”

- Enable activation delay of alarm #1

“AL-1”

- Enter value for alarm #1

“Act2”

- Select operation mode of alarm #2

“rSt2”

- Select reset mode of alarm #2

“Stb2”

- Enable activation delay of alarm #2

“AL-2”

- Enter value for alarm #2

“AHYS”

- Enter hysteresis value for both alarms

Configuration 5,.Cooling

*

“CYC2”

- Enter cooling time proportioning cycle time

“GAN2”

- Enter cooling relative gain

“db-2”

- Enter heat/cool deadband or overlap

Configuration

6, Serial Communications

*

“bAUd”

- Select baud rate

“PArb”

- Select parity bit

“Addr”

- Enter unit address number

“Abrv”

- Select abbreviated or full mnemonic

transmissions

“PrAt”

- Enter automatic print rate

“PoPt”

- Select parameters to be included

in print-out

Configuration 7, Control Points

“CSEt”

- Select control point number for set-up 1, 2,

3, & 4

“SP-x”

- Enter setpoint value for selected control

point

“PId”

- Select if PID gain set to be loaded with

setpoint

“PB-x”

- Enter proportional band for selected

control point

*

“It-x”

- Enter integral time for selected control

point

*

“dt-x”

- Enter derivative time for selected control

point

*

Configuration 8, Profiles

“PSEt”

- Select profile or event output for set-up 1,

2, 3, or 4

“PnCC”

- Enter program-repeat cycle count for

selected profile

“PnLn”

- Select link option for selected profile

“PnEb”

- Enter error band for temperature

conformity for selected profile

“PnPC”

- Enter power-down resume status for

selected profile

“Pnr1”

- Enter ramp rate 1 for selected profile

*

“PnL1”

- Enter setpoint level 1 for selected profile

*

“PnH1”

- Enter hold time 1 for selected profile

*

. .

. .

“Pnr8”

- Enter ramp rate 8 for selected profile

*

“PnL8”

- Enter setpoint level 8 for selected profile

*

“PnH8”

- Enter hold time 8 for selected profile

*

“Pn 1”

- Select event outputs at phase 1 for

selected profile

*

. .

. .

“Pn16”

- Select event outputs at phase 16 for

selected profile

*

Configuration 9, Factory Service Operations

(Detailed in the operator’s manual)

*

These parameters may not appear due to option configuration or other

programming

HARDWARE FEATURES

The fast 100 msec input sampling rate

provides quick controller response to a process

disturbance for excellent temperature control.

Measurement accuracy of 0.15% provides

closer process control conforming to the

desired control setpoint value.

The unit accepts a variety of both

thermocouple or RTD temperature probes.

The A.C. input power is switch selectable,

allowing the unit to operate from either 115

VAC or 230 VAC. Since the controller is

serviceable from the front of the panel, the

output modules may be easily changed or

replaced without disturbing the wiring behind

the panel and NO re-programming is required.

The standard model simply requires pressing a

latch to remove the unit. The Type 4X/IP65

rated model utilizes two panel securing screws

and a neoprene gasket to guarantee a water

tight seal, when properly installed.

Low-drift, highly stable circuit design

ensures years of reliable and accurate temperature control. The recommended

two year re-calibration interval is easily accomplished via the programming

menu.

SETPOINT FEATURES

The controller’s setpoint can be protected from out of range values, by

programming the setpoint range limit values. Additionally, safeguards from

inadvertent data entry can also be programmed.

The setpoint ramp feature ramps the setpoint value at start-up or any time a

setpoint change is made, at a user programmable rate, independent of a

programmed profile. This feature reduces thermal shock to the process and

also helps to minimize temperature overshoot.

The active setpoint, which can be a running profile, may also be transmitted

by the linear DC output for slave control loops.

Four control points are available which can be implemented at any time.

Each control point is programmed independently, with each having a setpoint

and a PID gain set value. With gain value changes, the output power control

signal will not “bump” resulting in a smooth control transition.

INPUT FEATURES

A programmable input filter can be used to stabilize readings from a process

with varying or oscillating temperature characteristics, helping to provide

better temperature control.

A programmable temperature shift and slope function can be used to

compensate for probe errors or to have multiple TSC units indicate the same

nominal temperature.

A programmable User Input is available to control a variety of controller

functions, such as profile control, auto/manual transfer, serial communication

print requests, etc.

DSP

PAR

%PW

PGM

MAN

OP1

AL1

AL2

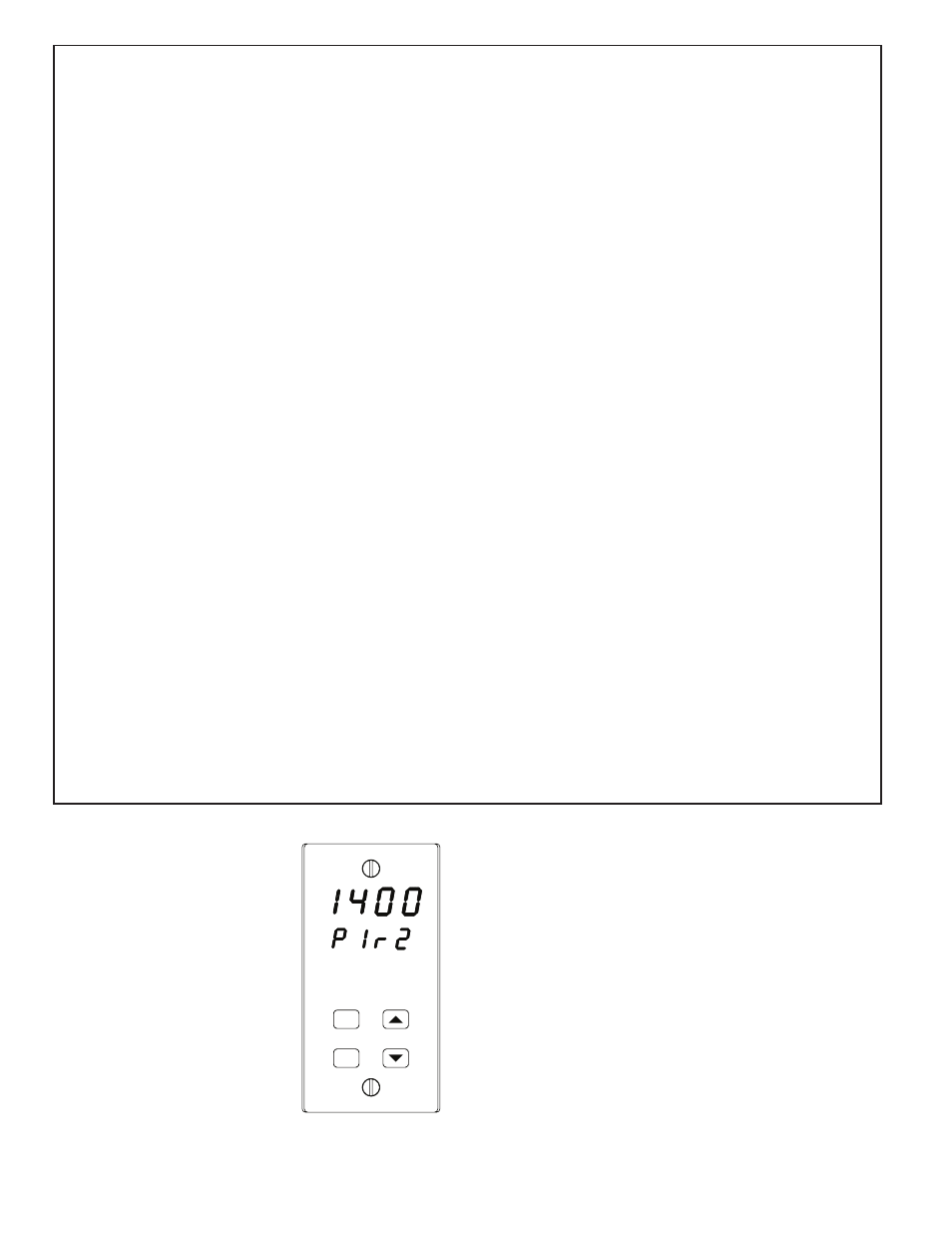

Type 4X/IP65 BEZEL