Controller programming, Setpoint master control – Red Lion TCU User Manual

Page 6

CONTROLLER PROGRAMMING

The TCU has been designed to reduce the operator interaction with the

controller while still maintaining a high degree of control accuracy and user

flexibility. Front Panel Program Disable allows all of the controller’s set-ups to be

locked-out from further operator intervention after the initial parameter set-up.

The programming of the controller is divided into four sections:

Unprotected Parameter Mode

Configuration Parameter Mode

Protected Parameter Mode

Hidden Function Mode

These four programming modes allow the controller to adapt to any required

user-interface level.

UNPROTECTED PARAMETER MODE

*

The unprotected parameter mode is accessible when program disable is

inactive or when the proper access code number from the protected mode is

entered.The configuration parameter modes can be accessed only from this mode.

“SP”

- Enter Setpoint

“OP”

- Enter output power

“ProP” - Enter proportional band

“Intt”

- Enter integral time

“dErt” - Enter derivative time

“rtio”

- Enter Remote Setpoint ratio value

“bIAS” - Enter Remote Setpoint bias value

“SP-2” - View internal cascade secondary setpoint

demand

“Pb-2” - Enter internal cascade, secondary

proportional band

“It-2”

- Enter internal cascade, secondary integral

time

“dt-2” - Enter internal cascade, secondary

derivative time

“AL-1” - Enter value for alarm #1

“AL-2” - Enter value for alarm #2

“CNFP” - Select basic configuration mode

“End” - Return to normal display mode

*

These parameters may not appear due to option configuration or other

programming.

CONFIGURATION PARAMETER MODE

The configuration parameter mode allows the operator to set-up the basic

requirements of the controller. It is divided into sections which group together

related programming steps, such as inputs, outputs, alarms, etc. Upon

completion of each section, the program returns to the configuration selection

stage allowing the user to return to the normal display mode.

Configuration 1, Inputs

“tYPE” - Select input probe type

“SCAL” - Select temperature scale

“dCPt” - Select temperature resolution

“FLtr” - Select level of input filtering

“SPAN” - Enter input correction span (slope)

“SHFt” - Enter input correction shift (offset)

“SPLO” - Enter setpoint lower limit

“SPHI” - Enter setpoint higher limit

“SPrP” - Enter setpoint ramp rate

“InPt” - Select user input function

*

“HCur” - Enter full scale heater current

*

Configuration 2, Outputs

“CYCt” - Enter time proportioning cycle time

“OPAC” - Select control action

“OPLO” - Enter output power low limit

“OPHI” - Enter output power high limit

“OPFL” - Enter probe fail power preset

“OPdP” - Enter output control dampening

“CHYS” - Enter ON/OFF control hysteresis

“tcod” - Select auto-tuning dampening

“ANAS” - Select linear DC output assignment

*

“ANLO” - Enter linear DC output low scaling value

*

“ANHI” - Enter linear DC output high scaling value

*

“ANdb” - Enter linear DC output control deadband

*

“ANUt” - Enter linear DC output update time

*

Configuration 3, Parameter lock-outs

“SP”

- Select degree of setpoint access

“OP”

- Select degree of power access

“dEv” - Enable deviation display

*

“IN-2” - Enable second input display

*

“HCur” - Enable heater current display

“UdSP” - Enable temperature scale display

“CodE” - Enter parameter access code

“PId”

- Select degree of PID access

“PId2” - Select degree of secondary PID access

*

“rtbS” - Select degree of ratio/bias access

*

“AL”

- Select degree of alarm access

*

“ALrS” - Enable alarm reset access

*

“SPSL” - Enable local/remote setpoint selection

*

“trnF” - Enable auto/manual mode selection

“tUNE” - Enable auto-tune invocation

Configuration 4, Alarms

*

“Act1” - Select operation mode of alarm #1

“rSt1” - Select reset mode of alarm #1

“Stb1” - Enable activation delay of alarm #1

“AL-1” - Enter value for alarm #1

“Act2” - Select operation mode of alarm #2

“rSt2” - Select reset mode of alarm #2

“Stb2” - Enable activation delay of alarm #2

“AL-2” - Enter value for alarm #2

“AHYS” - Enter hysteresis value for both alarms

Configuration 5, Cooling

*

“CYC2” - Enter cooling time proportioning cycle time

“GAN2” - Enter cooling relative gain

“db-2” - Enter heat/cool deadband or overlap

DSP

PAR

%PW

SEC

REM

OP1

AL1

AL2

DSP

PAR

DEV

%PW

OP1 AL2

MAN AL1

REMOTE SETPOINT

MASTER

UNIT

SLAVE

UNIT #1

PROCESS #1

PROCESS #2

MAIN

INPUT

MAIN

INPUT

SECOND INPUT

%PW REM AL1

AL2

MAIN

INPUT

PROCESS "N"

DSP

PAR

OP1

SEC

REMOTE SETPOINT

SECOND INPUT

(UP TO 50)

SLAVE

UNIT `N'

LINEAR DC OUTPUT SETPOINT RE-TRANSMISSION

6

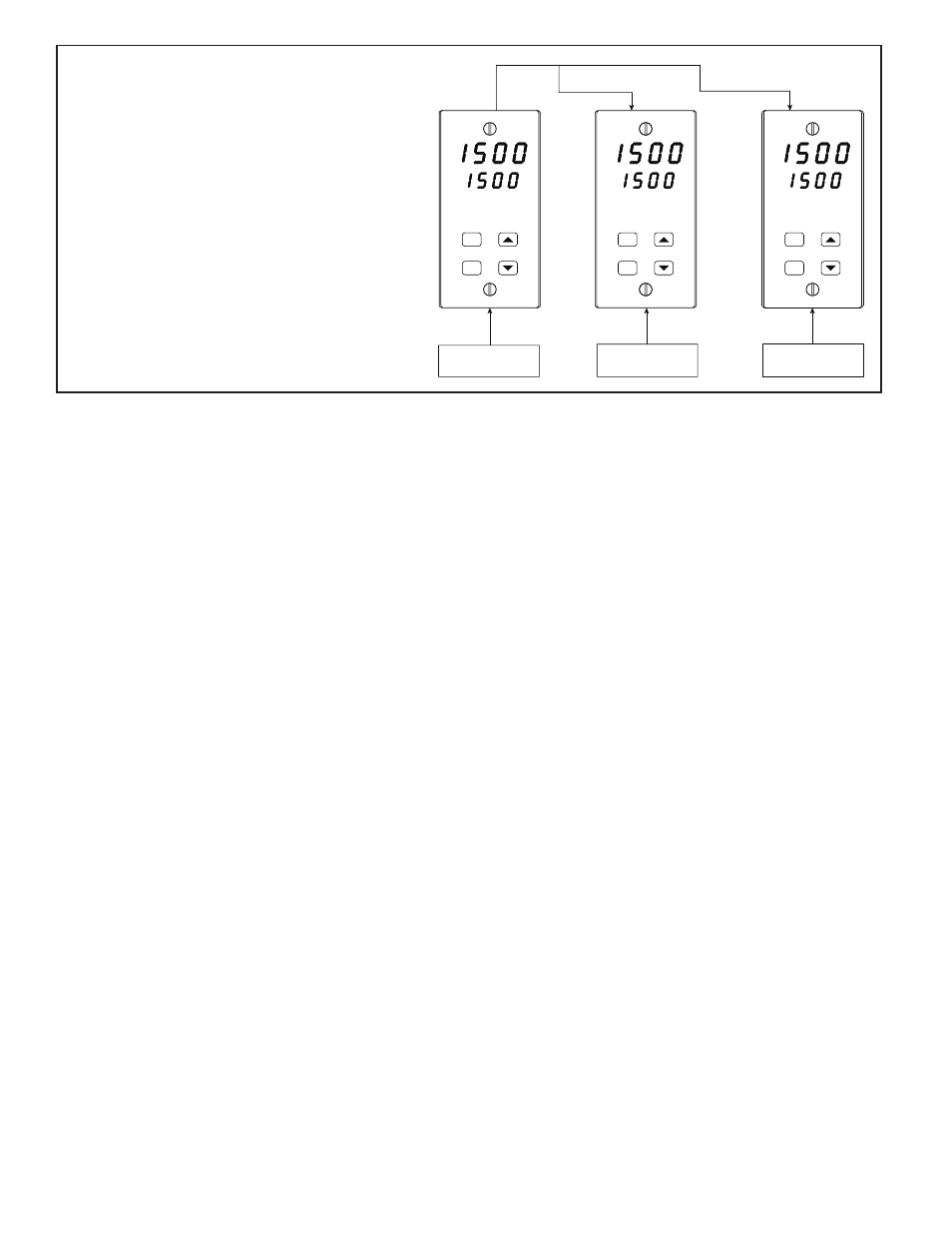

SETPOINT MASTER CONTROL

Setpoint Master Control allows automatic setpoint changes to slave

controller units (up to 50 units total) from a master TCU controller.

The linear DC output of the master is looped with the second analog

input of the slave TCU controllers. Each slave unit can have unique

remote setpoint ratio and bias values.

Setpoint Slave Configuration Parameters

“OPEr” - Select remote setpoint mode

“root” - Select second input square root

Linearization

“dPt2” - Select second input decimal point

“dSP1” - Enter scaling units of second input

“INP1” - Enter scaling units of second input

“dSP2” - Enter scaling units of second input

“INP2” - Enter scaling units of second input

“SPLO”

“SPHI”

- Limit range of remote setpoint

“SPrP” - Limit rate of change of remote

setpoint

Setpoint Slave Operational Parameters

“rtio”

- Second input ratio

“bIAS” - Second input bias