Options, Heating and cooling control, Heater current monitor – Red Lion TCU User Manual

Page 5: Motorized valve positioner, Internal cascade, External cascade

5

OPTIONS

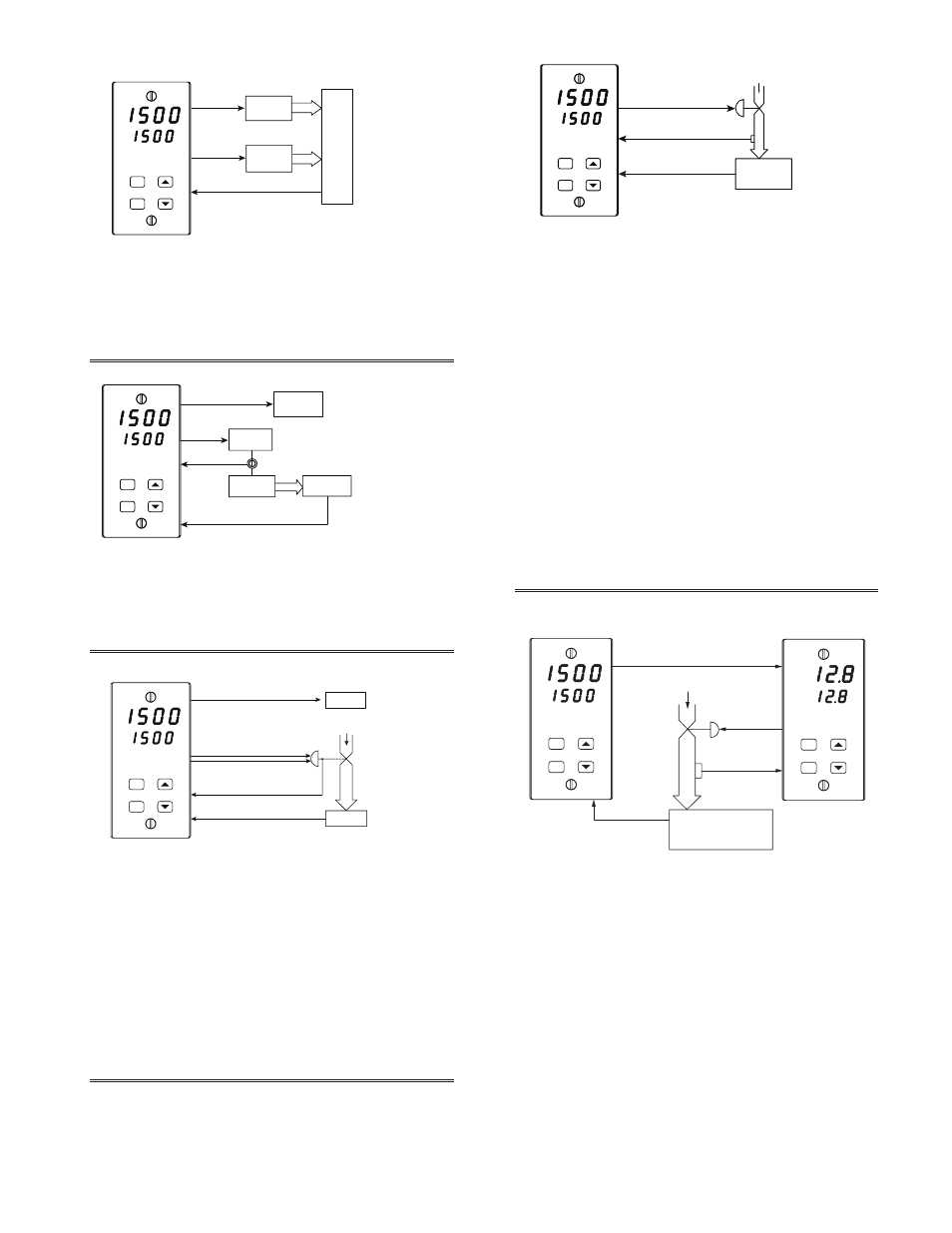

HEATING AND COOLING CONTROL

The TCU has dual outputs for providing heating and cooling to those

processes that require them. Many extruder applications require both heating

and cooling to maintain accurate extruder barrel and die temperatures. The TCU

is easily configured for these applications.

Cooling Configuration Parameters

“CYC2”

- Enter cooling time proportioning cycle time

“GAN2”

- Enter cooling relative gain

“db-2”

- Enter heat/cool deadband or overlap

HEATER CURRENT MONITOR

The Heater Current Monitor serves as a heater element fail sentry, so

operators can take corrective action before significant process errors occur in

the event of a failure. The actual heater current can be viewed in the secondary

display and/or a heater break alarm output can be programmed.

Heater Current Monitor Configuration Parameters

“HCur”

- Enter full scale current of current transformer

ACt1”, “ACt2”

- Program alarm(s) as heater break alarm

MOTORIZED VALVE POSITIONER

The motorized valve positioner controls the position of a valve directly, by use

of “open” and “close” control outputs. The slidewire feedback signals of the valve

may optionally be connected to the controller. Alternatively, the controller may be

configured for linear input valve control using the 4 to 20 mA DC output.

Motorized Valve Positioner Configuration Parameters

Position mode: “VPS1”

- Enter or measure valve closed position

“VPS2”

- Enter or measure valve open position

“VUdt”

- Enter Valve update time

“VPdb”

- Enter valve control deadband

“VFAL”

- Enter valve fail detect time

“Act1”

- Program alarm as valve fail output

Velocity mode: “VUdt”

- Enter Valve update time

“VOPt”

- Enter valve open time

“VCLt”

- Enter valve close time

“VONt”

- Enter valve control deadband

(minimum on time)

INTERNAL CASCADE

Cascade control allows the process to be divided into two control loops: the

primary control loop and the secondary control loop. The secondary loop

receives it’s setpoint from the primary loop to control an intermediate variable

(steam pressure). The control level of the intermediate variable is the input to

the primary process. The primary loop (temperature) controller maintains loop

regulation by manipulating the setpoint of the secondary controller. The

setpoint of the secondary controller, in turn, changes the intermediate variable.

The secondary loop can react faster to disturbances of the intermediate variable,

thereby minimizing the effects to the primary control loop. Control loops

cascaded in such a manner provide greater control quality than would be

possible with single loop control. A single TCU can accomplish two-process

cascade control.

Internal Cascade Configuration Parameters

“OPer”

- Select cascade mode

“root”

- Select second input square root linearization

“dPt2”

- Select second input decimal point

“dSP1”

- Enter scaling units of second input

“INP1”

- Enter scaling units of second input

“dSP2”

- Enter scaling units of second input

“INP2”

- Enter scaling units of second input

“OPd2”

- Output dampening of secondary

Internal Cascade Operational Parameters

“SP-2”

- View secondary setpoint value

“Pb-2”

- Enter secondary proportional band

“It-2”

- Enter secondary integral time

“dt-2”

- Enter secondary derivative time

EXTERNAL CASCADE

Similar to internal cascade control, external cascade control differs by the

employment of two controllers, one of which is equipped with a second analog

input configured as a remote setpoint. A PCU controls the secondary loop, while

a TCU controls the primary loop.

External Cascade Configuration Parameters

“OPEr”

- Select ratio mode

“root”

- Select second input square root linearization

“dPt2”

- Select second input decimal point

“dSP1”

- Enter scaling units of second input

“INP1”

- Enter scaling units of second input

“dSP2”

- Enter scaling units of second input

“INP2”

- Enter scaling units of second input

“SPtr”

- Local/Remote select options

External Cascade Operational Parameters

“rtio”

- Remote setpoint ratio

“bIAS”

- Remote setpoint bias

DSP

PAR

%PW

DEV

MAN

AL1

OPN

CLS

VALVE OPEN OUTPUT

VALVE CLOSE OUTPUT

SECOND INPUT

VALVE POSITION

MAIN INPUT

PROCESS

STEAM FLOW

VALVE FAIL

ALARM

AL1 OUTPUT

DSP

PAR

%PW

SEC

REM

OP1

AL1

AL2

LINEAR DC OUTPUT

SECOND INPUT

STEAM PRESSURE

STEAM

FLOW

PROCESS

MAIN INPUT

TEMPERATURE

(SECONDARY VARIABLE)

(PRIMARY VARIABLE)

DSP

PAR

%PW

DEV

MAN

OP1

AL1

AL2

OP1

REM

DSP

PAR

SEC

%PW

AL2

AL1

CONTROLLER

CONTROLLER

LINEAR DC

(PRIMARY OUTPUT)

SECOND INPUT

REMOTE SETPOINT

STEAM

LINEAR DC

OUTPUT

MAIN INPUT

PROCESS TEMPERATURE

(PRIMARY VARIABLE)

PROCESS

MAIN INPUT

STEAM PRESSURE

(SECONDARY VARIABLE)

PCU

TCU

SECONDARY

PRIMARY

DSP

PAR

%PW

CUR

MAN

OP1

AL1

AL2

POWER

CONTROL

DEVICE

HEATING

ELEMENT

PROCESS

CURRENT TRANSFORMER

MAIN INPUT

TEMPERATURE

HEATER

CURRENT

MAIN

OUTPUT

(OP1)

HEATER BREAK

ALARM

AL1 OUTPUT

DSP

PAR

%PW

DEV

MAN

OP1

AL1

OP2

PROCESS

HEATING

CONTROL

COOLING

CONTROL

MAIN OUTPUT

(OP1)

SECOND OUTPUT

(OP2)

MAIN INPUT

TEMPERATURE

5