4 module 4 - s, Sec lo-t hi-t dsp-t b-lit, At-t at-b offst – Red Lion LDSG User Manual

Page 11: Econdary, Unction, Arameters

11

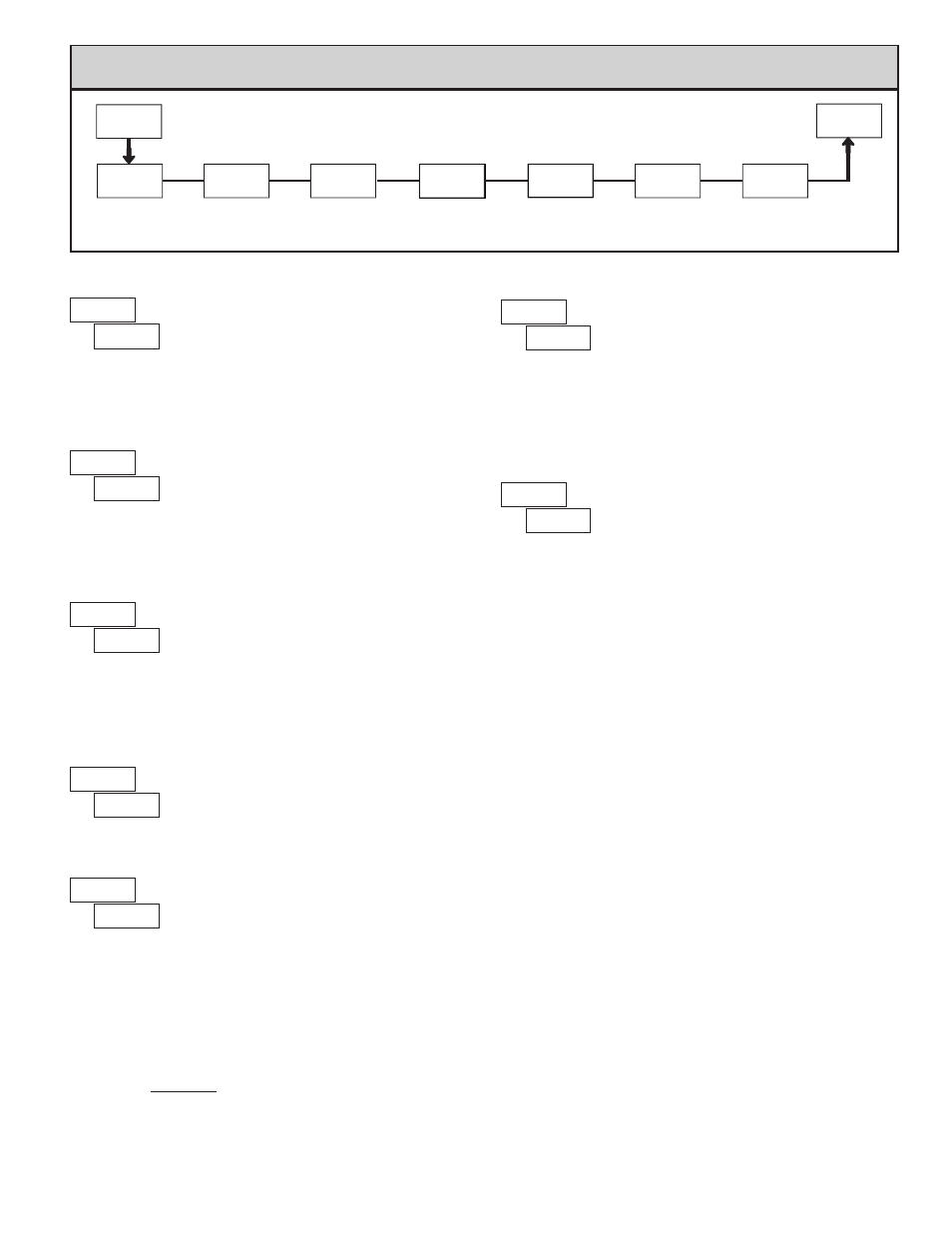

MAX CAPTURE DELAY TIME*

When the Input Display is above the present MAX value for the entered

delay time, the meter will capture that display value as the new MAX reading.

A delay time helps to avoid false captures of sudden short spikes.

MIN CAPTURE DELAY TIME*

When the Input Display is below the present MIN value for the entered delay

time, the meter will capture that display value as the new MIN reading. A delay

time helps to avoid false captures of sudden short spikes.

UNITS LABEL BACKLIGHT*

This parameter is not used on this unit.

DISPLAY OFFSET VALUE*

Unless a Zero Display was performed or an offset from Module 1 scaling is

desired, this parameter can be skipped. The Display Offset Value is the

difference from the Absolute (gross) Display value to the Relative (net) Display

value for the same input level. The meter will automatically update this Display

Offset Value after each Zero Display. The Display Offset Value can be directly

keyed-in to intentionally add or remove display offset. See Relative / Absolute

Display and Zero Display explanations in Module 2.

DISPLAY UPDATE RATE*

This parameter determines the rate of display update. When set to 20

updates/second, the internal re-zero compensation is disabled, allowing for the

fastest possible output response.

4-SEC

LO-t

HI-t

dSP-t

b-LIt

PAR

Pro

Max. Capture

Delay Time

Min. Capture

Delay Time

Display Update

Time

Units Label

BackLight

Auto-Zero

Tracking Delay

Time

At-t

At-b

OFFSt

Display Offset

Value

Auto-Zero

Tracking Band

6.4 Module 4 - s

econdary

F

unctIon

p

araMeters

(

)

PARAMETER MENU

*

Factory Setting can be used without affecting basic start-up.

to

sec.

to

sec.

to

updates/sec.

AUTO-ZERO TRACKING

to

sec.

AUTO-ZERO BAND

to

The meter can be programmed to automatically compensate for zero drift.

Drift may be caused by changes in the transducers or electronics, or

accumulation of material on weight systems.

Auto-zero tracking operates when the readout remains within the tracking

band for a period of time equal to the tracking delay time. When these

conditions are met, the meter re-zeroes the readout. After the re-zero operation,

the meter resets and continues to auto-zero track.

The auto-zero tracking band should be set large enough to track normal zero

drift, but small enough to not interfere with small process inputs.

For filling operations, the fill rate must exceed the auto-zero tracking rate.

This avoids false tracking at the start of the filling operation.

Fill Rate ≥ tracking band

tracking time

Auto-zero tracking is disabled by setting the auto-zero tracking parameter = 0.