Features and components – State SBD85 365NE A User Manual

Page 7

7

features and components

the hydrocannon (self-cleaning system)

These units include The Hydrocannon (Self-Cleaning System)

installed in the front water inlet, See Figure 1. The Hydrocannon

inlet tube can only be used in the front water inlet connection. Do

not install the Hydrocannon inlet tube in either the top or back inlet

water connection. The Hydrocannon must be oriented correctly for

proper function. There is a marked range on pipe nipple portion

of the Hydrocannon, that must be aligned with top of inlet spud. A

label above the jacket hole has an arrow that will point to marked

portion of pipe nipple if the orientation is correct. If the arrow does

not point within the marked range on pipe nipple, adjust the pipe

nipple to correct. A pipe union is supplied with the Hydrocannon

to reduce probability of misaligning the Hydrocannon accidentally

while tightening the connection to inlet water supply line. Improper

orientation of the Hydrocannon can cause poor performance of

heater and can significantly reduce outlet water temperatures

during heavy draws.

note: the hydrocannon may have 1, 3 or 7 cross tubes.

figure 1.

high limit switch

The digital thermostat (Figure 2) contains the high limit (energy

cutout) switch. The high limit switch interrupts main burner gas flow

should the water temperature reach 203°F (95°C).

In the event of high limit switch operation, the water heater cannot be

restarted unless the water temperature is reduced to approximately

120°F (49°C). The high limit reset button on the front of the control

then needs to be depressed.

Continued manual resetting of high limit control, preceded by higher

than usual water temperature is evidence of high limit switch operation.

The following is a possible reason for high limit switch operation:

• A malfunction in the thermostatic controls would allow the

gas control valve to remain open causing water temperature

to exceed the thermostat setting. The water temperature

would continue to rise until high limit switch operation.

Contact your dealer or service agent if continued high limit switch

operation occurs.

digital thermostat

figure 2.

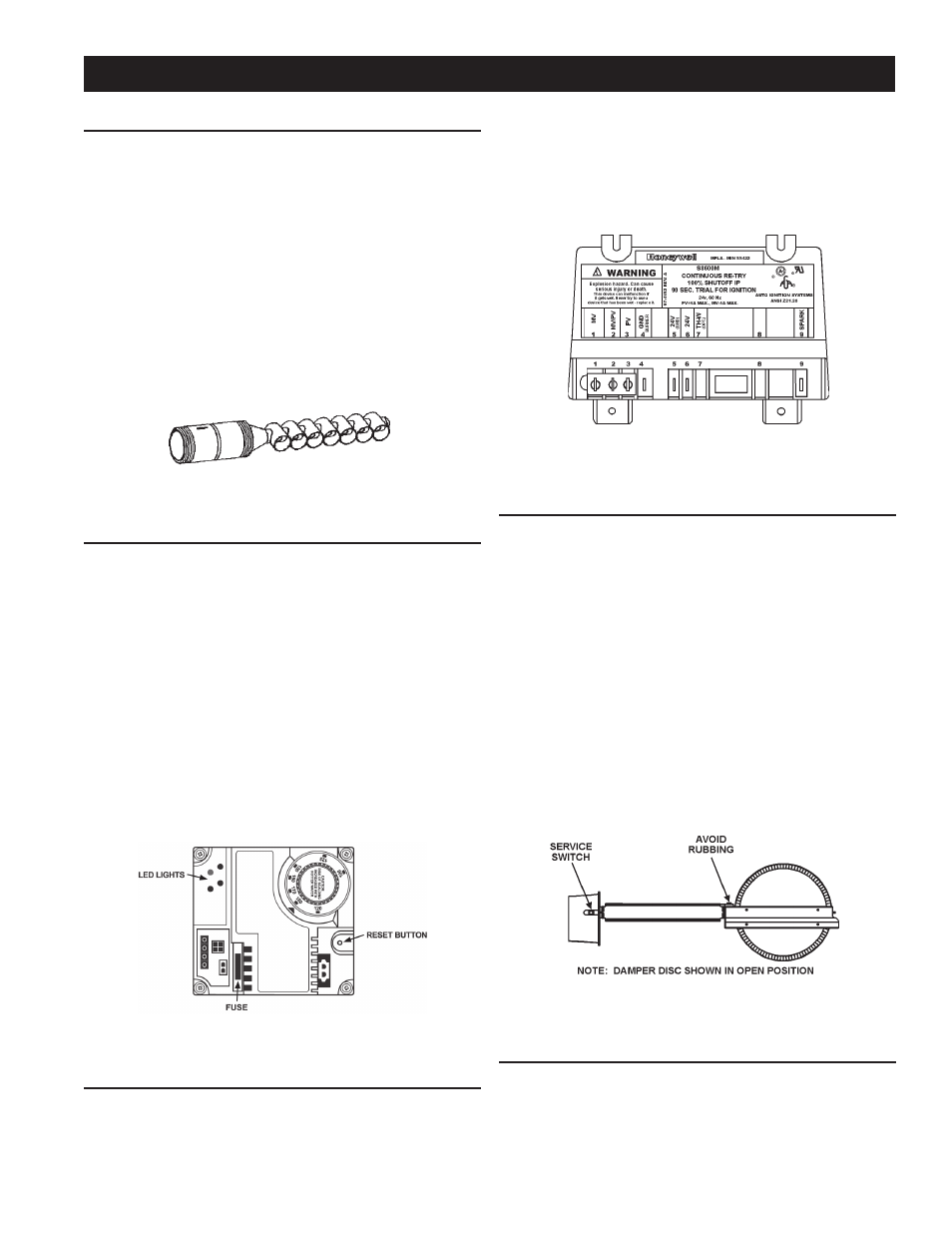

electronic ignition control

Each heater is equipped with a Honeywell ignition module. The

solid state ignition control ignites the pilot burner gas by

creating a spark at the pilot assembly. See Figure 3. Pilot

gas is ignited and burns during each running cycle. The main

burner and pilot gases are cut off during the OFF cycle.

Pilot gas ignition is proven by the pilot sensor. Main burner

ignition will not occur if the pilot sensor does not first sense

pilot ignition.

ignition module

figure 3.

automatic flue damper

All units are equipped with an automatic flue damper that

reduces heat loss during the OFF cycles.

Each automatic flue damper drive assembly is equipped with a

“Service Switch”, as shown in Figure 4

The “Ser vice Switch” has 2 positions: AUTOMATIC

OPERATION and HOLD OPEN DAMPER. For normal operation

the switch should be in the AUTOMATIC OPERATION position.

If there is a problem with the damper the “Service Switch”

can be placed in the HOLD OPEN DAMPER position. When

the switch is placed in the HOLD OPEN DAMPER position

the damper disc will rotate to the open position and the

heater may be used until vent assembly is repaired or

replaced. DO NOT turn the damper disc manually; damage

will occur to the drive assembly if operated manually. Refer

to TESTING DAMPER OPERATION section of this manual

for additional information.

flue damper

figure 4.

uncrating

The heater is shipped with the flue damper already installed. The

wiring conduit runs from the thermostat to the damper drive cover.

Before turning unit on, check to make sure the wiring conduit is

securely plugged into damper drive.