State SBD85 365NE A User Manual

Page 29

29

adjustments

ON INITIAL STARTUP SOME ADJUSTMENTS MAY BE NECESSARY.

Check Manifold and inlet gas pressures (see GAS SUPPLY

SYSTEMS on page 13 and CHECKING THE INPUT on page 29-30.)

Check Pilot Burner (See Pilot Burner section on page 34.)

TESTING DAMPER OPERATION

With the Service Switch in the AUTOMATIC OPERATION

position, check the operation of the flue damper three (3) times

with the water operating controls for proper operating sequence:

• The damper disc must be open (in the vertical position) before

the ignition and combustion process begins.

• The damper disc must be in the open position when the main

burner is firing.

• The gas control valve must close and the main burner must

have ceased firing before the damper disc begins its return to

the closed (horizontal) position.

If during testing of the operation of the damper you find that

there is a problem with the operation of the water heater when

the Service Switch is in the AUTOMATIC OPERATION position:

Reset the Service Switch to the HOLD OPEN DAMPER position

and check operation again.

If the water heater does operate when placed in the HOLD OPEN

DAMPER position:

• Refer to the EFFIKAL RVGP-FSF-SERIES TROUBLESHOOTING

GUIDE on page 37.

If the water heater does not operate with the Service Switch in

either position:

• Refer to the Troubleshooting Sections and Troubleshooting

Checklist.

checking Venting

The following steps shall be followed with each appliance connected

to the venting system placed in operation, while any other appliances

connected to the venting system are not in operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as

required in the National Fuel Gas Code, ANSI Z223.1or the CAN/

CGA B149 Installation Codes and these instructions. Determine

that there is no blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe condition.

3. So far as is practical, close all building doors and windows

and all doors between the space in which the water heater(s)

connected to the venting system are located and other spaces

of the building. Turn on all appliances not connected to the

venting system. Turn on all exhaust fans, such as range hoods

and bathroom exhausts, so they shall operate at maximum

speed. Close fireplace dampers.

4. Follow the lighting instruction. Place the water heater being

inspected in operation. Adjust thermostat so water heater shall

operate continuously.

5. Test for draft hood spillage at the relief opening after 5 minutes

of main burner operation.

6. After it has been determined that each appliance connected to

the venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace dampers and any

other gas burning appliance to their previous conditions of use.

7. If improper venting is observed during any of the above tests,

the venting system must be corrected.

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

• If the back draft cannot be corrected by the normal method or

if a suitable draft cannot be obtained, a blower type flue gas

exhauster must be employed to assure proper venting and

correct combustion.

checking the input

For installation locations with elevations above 2000 feet, refer

to HIGH ALTITUDE INSTALLATIONS section of this manual for

input reduction procedure.

1. Attach a pressure gauge or a manometer to the manifold

pressure tap on the gas control valve and refer to Table 8,

for correct manifold pressure.

2. Use this formula to “clock” the meter. Be sure that other

gas consuming appliances are not operating during this

interval.

(3600/T) x H = Btuh

T = Time in seconds to burn one cubic foot of gas.

H = Btu’s per cubic foot of gas.

Btuh = Actual heater input.

Example:

T = 15.1 seconds

H = 1050 Btu

Btuh = ?

(3600/15.1) x 1050 = 250,000

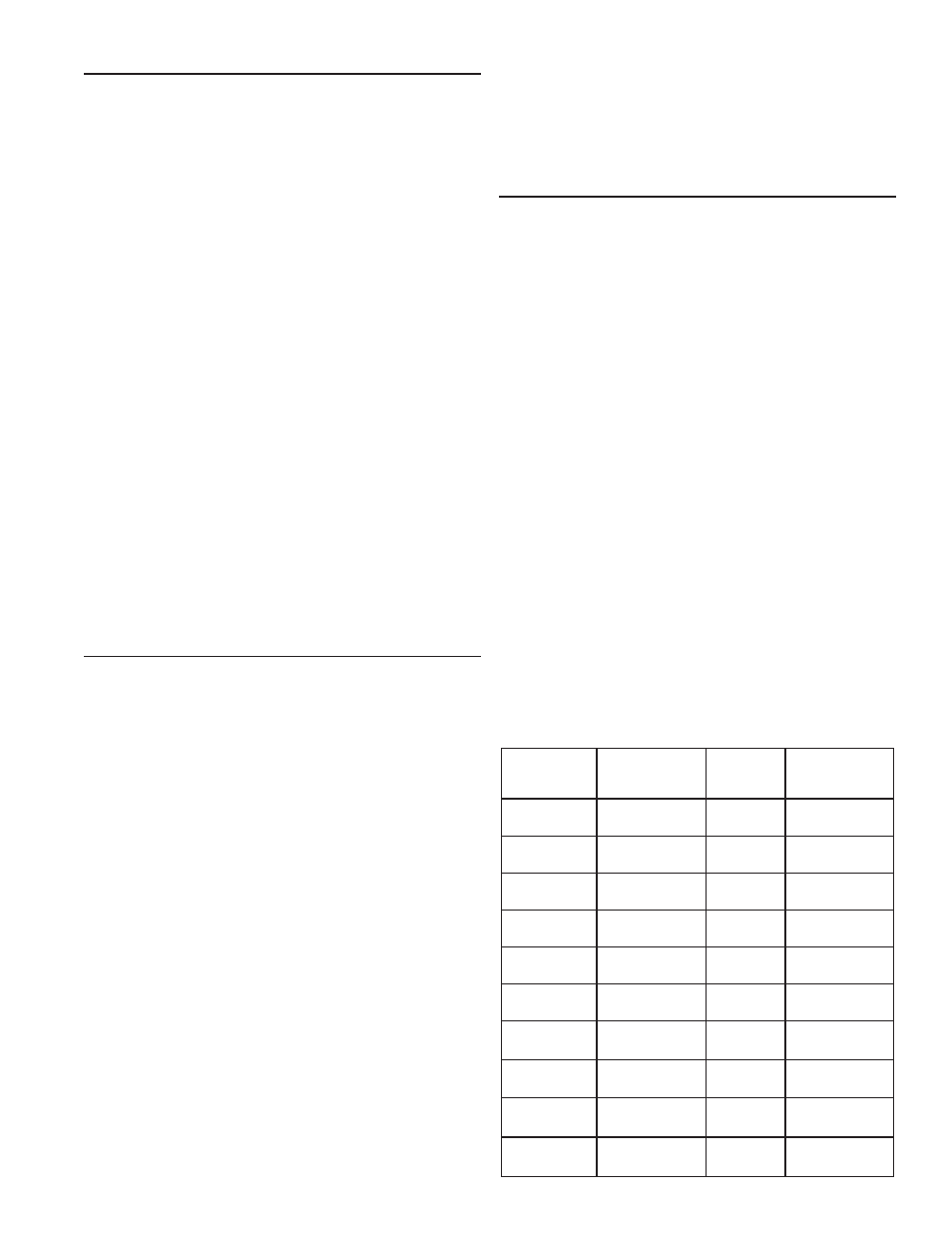

taBle 8.

approXimate time reQuired to consume

1 cu. ft. of gas at full capacity

input

rate

(Btuh)

type

of

gas

Btuh

per

cu. ft.

time reQ’d to

consume 1 cu.

ft. of gas

120,000

NATURAL

PROPANE

1050

2500

31. 5 SEC.

75.0 SEC.

154,000

NATURAL

PROPANE

1050

2500

24.5 SEC.

58.4 SEC.

180,000

NATURAL

PROPANE

1050

2500

21.0 SEC.

50.0 SEC.

199,000

NATURAL

PROPANE

1050

2500

19.0 SEC.

45.2 SEC.

250,000

NATURAL

PROPANE

1050

2500

15.1 SEC.

36.0 SEC.

251,000

NATURAL

PROPANE

1050

2500

15.1 SEC.

35.9 SEC.

275,000

NATURAL

PROPANE

1050

2500

13.7 SEC.

32.7 SEC.

305,000

NATURAL

PROPANE

1050

2500

12.4 SEC.

29.5 SEC.

365,000

NATURAL

PROPANE

1050

2500

10.4 SEC.

24.7 SEC.

390,000

NATURAL

PROPANE

1050

2500

9.7 SEC.

23.1 SEC.