Troubleshooting – State SBD85 365NE A User Manual

Page 36

36

receptacle. Do not push meter leads into harness receptacle.

This opens the pins and will create connection problems. See

the following EFFIKAL RVGP-KSF-SERIES FLUE DAMPER

TROUBLE SHOOTING GUIDE.

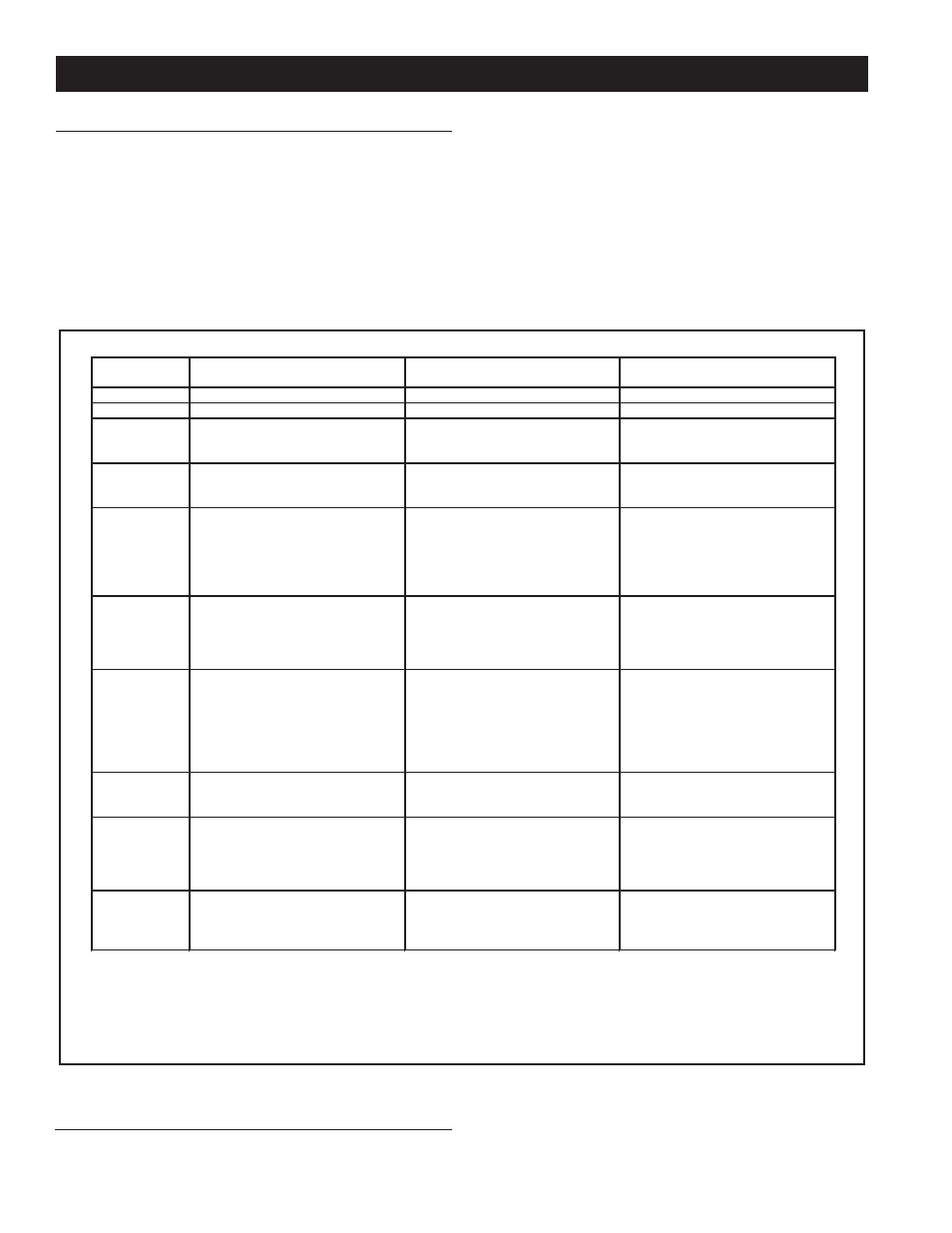

Green LED

Flash Code

a

Indicates

Next System Action

Recommended Service Action

OFF

No “Call for Heat”

Not applicable

None

Flash Fast

Power up - internal check

Not applicable

None

Heartbeat

Norma l startup – ignition

sequence started (including

prepurge)

Not applicable

None

4 Seconds

ON then “x”

flashes

Device in run mode. “x” = flame

current to the nearest μ A.

Not applicable

None

2

5 minute Retry Delay - Pilot flame

not detected during trial for ignition

Initiate new trial for ignition after

retry delay completed.

If system fails to light on next trial

for ignition check gas supply, pilot

burner, spark and flame sense

wiring, flame rod contaminated or

out of position, burner ground

connection.

3

Recycle - Flame failed during run

Initiate new trial for ignition. Flash

code will remain through the

ignition trial until flame is proved.

If system fails to light on next trial

for ignition, check gas supply, pilot

burner, flame sense wiring,

contamination of flame rod, burner

ground connection.

4

Flame sensed out of sequence

If situation self corrects within 10

seconds, control returns to normal

sequence. If flam e out of

sequence remains longer than 10

seconds, control will resume

normal operation 1 hour after error

is corrected.

Check for pilot flame. Replace gas

valve if pilot flame present. If no

pilot flame, cycle “Call for Heat.” If

error repeats, replace con trol.

6

Control Internal Error

Control remains in wait mode.

When the fault corrects, control

resumes normal operation.

Cycle “Call for Heat”. If error

repeats, replace control.

7

Flame rod shorted to ground

Control remains in wait mode.

When the fault corrects, control

resumes normal operation.

Check flame sense lead wire for

damage or shorting. Check that

flame rod is in proper position.

Check flame rod ceramic for

cracks, damage or tracking.

8

Low secondary voltage supply

Control remains in wait mo de.

When the fault corrects, control

resumes normal operation.

Check transformer and AC line for

proper input voltage to the control.

Check with full system load on the

transformer.

a

Flash Code Descriptions:

- Flash Fast: rapid blinking.

- Heartbeat: Constant ½ second bright, ½ second dim cycles.

- 4 second solid on pulse followed by “x” 1 second flashes indicates flame current to the nearest μ A. This is only available in run mode.

- A single flash code number signifies that the LED flashes X times at 2H z, remains off for two seconds, and then repeats the sequence.

ignition module

Before calling your service agent, the following checklist should

be examined to eliminate obvious problems from those requiring

replacement or servicing.

• Check that “main manual gas shut-off valve” is fully open

and that gas service has not been interrupted.

• Check that after following the water OPERATING

INSTRUCTIONS, the “Top Knob” of the gas control valve

is in “ON” position.

• Check electrical supply to the water heater for possible

blown (or tripped) fusing or power interruption.

• Is the water temperature in tank below the thermostat dial

setting on the thermostat (calling for heat)?

• It is possible that the high limit (E.C.O.) has functioned to shut

off the water heater. See FEATURES - Water Temperature

Control for reset procedure. Contact your serviceman if limit

continues to function to shut off water heater.

flue damper

Do not turn damper open manually or motor damage will result,

use the service switch. All readings are taken from harness

trouBleshooting