State SBD85 365NE A User Manual

Page 14

14

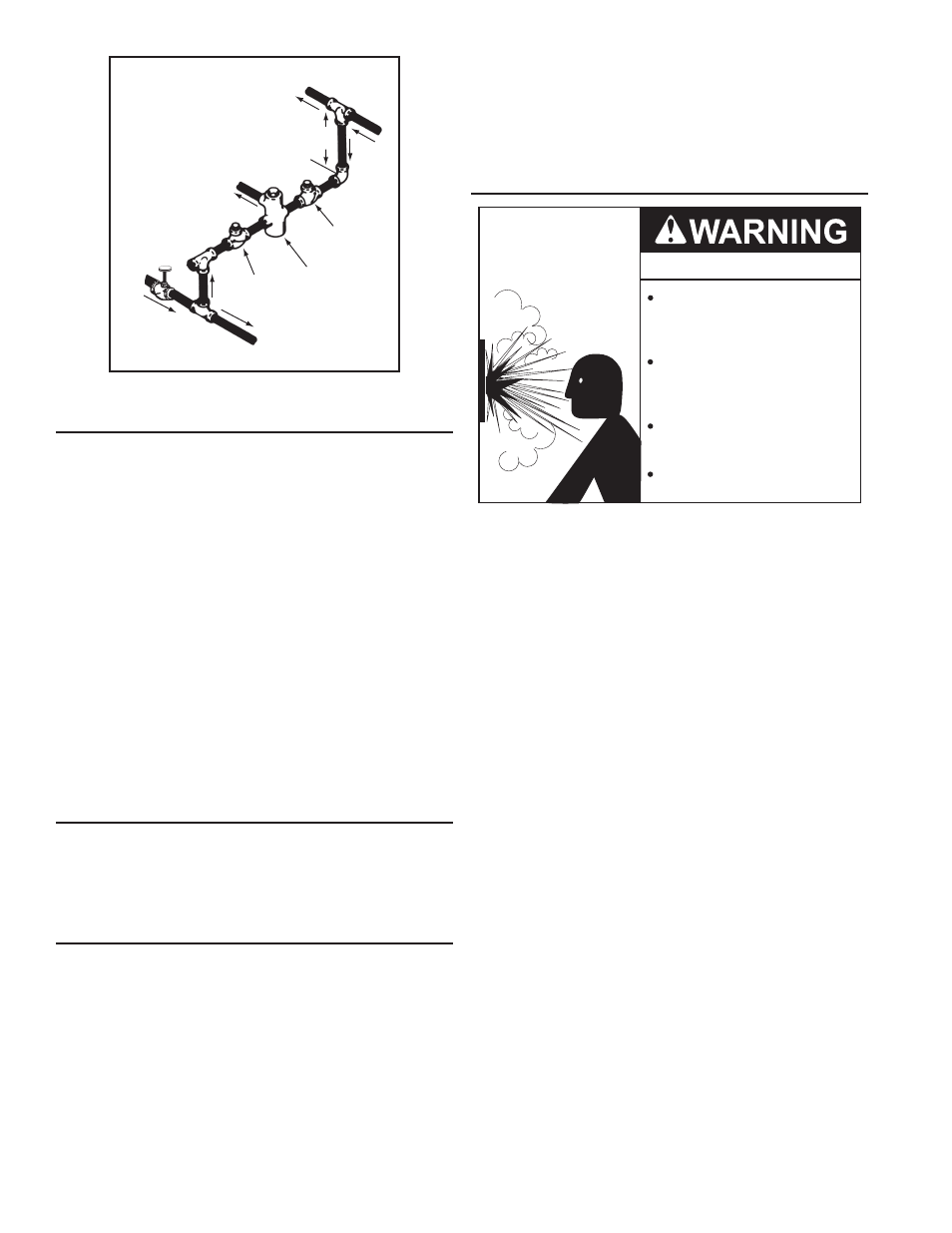

HOT WATER

OUTLET

TO TANK

INLET

CHECK

VALVE

MIXING

VALVE

COLD

WATER

INLET

TEMPERED WATER

OUTLET

12” TO 15”

(30-38 cm)

CHECK

VALVE

figure 10.

dishwashing machines

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water flow

pressures between 15 and 25 pounds per square inch (103 kPa

and 173 kPa). Flow pressures above 25 pounds per square inch

(173 kPa), or below 15 pounds per square inch (103 kPa), will

result in improperly sanitized dishes. Where pressures are high,

a water pressure reducing or flow regulating control valve should

be used in the 180°F (82°C) line to the dishwashing machine and

should be adjusted to deliver water pressure between these limits.

The National Sanitation Foundation also recommends circulation

of 180°F (82°C) water. The circulation flow rate should be just

enough to provide 180°F (82°C) water at the point of take-off to

the dishwashing machine.

Adjust flow by throttling a full port ball valve installed in the

circulating line on the outlet side of the pump. Never throttle flow

on the suction side of a pump. See Water Piping Diagrams in

this manual.

note: These water heaters meet the NSF Standard 5 for

sanitary installations when used with the leg kit part number

9003425205.

closed water systems

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back flow preventers. Devices such as these cause

the water system to be a closed system.

thermal eXpansion

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the

volume of water grows there will be a corresponding increase

in water pressure due to thermal expansion. Thermal expansion

can cause premature tank failure (leakage). This type of failure

is not covered under the limited warranty. Thermal expansion

can also cause intermittent Temperature-Pressure Relief Valve

operation: water discharged from the valve due to excessive

pressure build up. This condition is not covered under the limited

warranty. The Temperature-Pressure Relief Valve is not intended

for the constant relief of thermal expansion.

A properly sized thermal expansion tank must be installed on

all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

See Water Line Connections on page 21 and the Water Piping

Diagrams beginning on page 40.

temperature-pressure relief ValVe

Explosion Hazard

Temperature-Pressure Relief Valve

must comply with ANSI Z21.22-

CSA 4.4 and ASME code.

Properly sized temperature-

pressure relief valve must be

installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

This water heater is provided with a properly rated/sized and certified

combination Temperature-Pressure Relief Valve (T&P valve) by

the manufacturer. The valve is certified by a nationally recognized

testing laboratory that maintains periodic inspection of production

of listed equipment of materials as meeting the requirements for

Pressure Relief Valves for Hot Water Supply Systems, ANSI Z21.22

• CSA 4.4, and the code requirements of ASME.

If replaced, the new T&P valve must meet the requirements

of local codes, but not less than a combination Temperature-

Pressure Relief Valve rated/sized and certified as indicated in

the above paragraph. The new valve must be marked with a

maximum set pressure not to exceed the marked hydrostatic

working pressure of the water heater (150 psi = 1,035 kPa) and

a discharge capacity not less than the water heater Btu/hr or kW

input rate as shown on the water heater’s model rating label.

NOTE: In addition to the factory installed Temperature-Pressure

Relief Valve on the water heater, each remote storage tank that

may be installed and piped to a water heating appliance must also

have its own properly sized, rated and approved Temperature-

Pressure Relief Valve installed. Call the toll free technical

support phone number listed on the back cover of this manual

for technical assistance in sizing a Temperature-Pressure Relief

Valve for remote storage tanks.

For safe operation of the water heater, the Temperature-Pressure

Relief Valve must not be removed from its designated opening

nor plugged. The Temperature-Pressure Relief Valve must be

installed directly into the fitting of the water heater designed for

the pressure relief valve . Install discharge piping so that any

discharge will exit the pipe within 6 inches (15.2 cm) above an

adequate floor drain, or external to the building. In cold climates

it is recommended that it be terminated at an adequate drain

inside the building. Be certain that no contact is made with any

live electrical part. The discharge opening must not be blocked

or reduced in size under any circumstances. Excessive length,

over 30 feet (9.14 m), or use of more than four elbows can cause

restriction and reduce the discharge capacity of the valve.