State GPG 81 370NEA User Manual

Page 26

26

adjustments

1. Check gas line pressure and manifold pressure (Table 9) and

adjust as required.

2. Check barometric damper for proper operation. Parts must

move freely.

3. Allow the unit to operate for 15 minutes. Drain hot water from

the heater or storage tank to continue main burner operation.

4. Determine heat input rate (see CHeCkING THe INPuT

section below).

checking Venting

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while

any other appliances connected to the venting system are

not in operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1or the CAN/CGA B149 Installation Codes and

these instructions. Determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

3. So far as is practical, close all building doors and windows

and all doors between the space in which the water

heater(s) connected to the venting system are located and

other spaces of the building. Turn on all appliances not

connected to the venting system. Turn on all exhaust fans,

such as range hoods and bathroom exhausts, so they shall

operate at maximum speed. Close fireplace dampers.

4. Follow the lighting instruction. Place the water heater in

operation. Adjust thermostat so water heater shall operate

continuously.

5. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to their

previous conditions of use.

6. If improper venting is observed during any of the above

tests, the venting system must be corrected.

FAIlure TO COrreCT BACk DrAFTS mAy CAuSe AIr

CONTAmINATION AND uNSAFe CONDITIONS.

• If the back draft cannot be corrected by the normal method

or if a suitable draft cannot be obtained, a blower type flue

gas exhauster must be employed to assure proper venting

and correct combustion.

checking the input

For installation locations with elevations above 2000 feet, refer

to HIGH AlTITuDe INSTAllATIONS section of this manual

for input reduction procedure.

The input rate can be estimated by timing the meter, if no other

appliances are operating.

With a stopwatch, or a wristwatch, which can display the time

in seconds, read the gas meter and measure the amount of

time required for the heater to consume 5 cubic feet of gas. The

actual rate may then be estimated by using the formula below:

(3600/T) x H = Btuh

T = Time in seconds to burn one cubic foot of gas.

H = Btu’s per cubic foot of gas.

Btuh = Actual heater input.

example:

T = 15.1 seconds

H = 1050 Btu

Btuh = ?

(3600/15.1) x 1050 = 250,000

The input may be adjusted by adjusting the pressure regulator.

remove the top cap to expose the adjustment screw. Turning

the screw in increases the gas pressure and backing the

screw out decreases the pressure. Do not turn the adjusting

screw in past the point where no further increase in pressure

is noted.

The manifold pressure is measured at the line Pressure Tap,

see Figure 22, and should be used as a reference point for

making pressure regulator adjustments. Table 9 gives the

design manifold pressures for each model. Increase or reduce

the pressure as required to obtain the rated input.

If an acceptable rate cannot be achieved by adjusting the

pressure regulator (manifold pressure), first check to be

certain that the gas supply pressure to the unit is adequate.

If the supply pressure is inadequate, a different burner orifice

may be required. Obtain from the utility the heating value and

specific gravity of the gas at the site. Provide this information

and the altitude of the site to obtain a larger orifice size.

uNDer NO CIrCumSTANCeS SHOulD THe GAS INPuT

eXCeeD THe INPuT SHOWN ON THe HeATer mODel AND

rATING PlATe. OVerFIrING COulD reSulT IN DAmAGe

Or SOOTING OF THe HeATer.

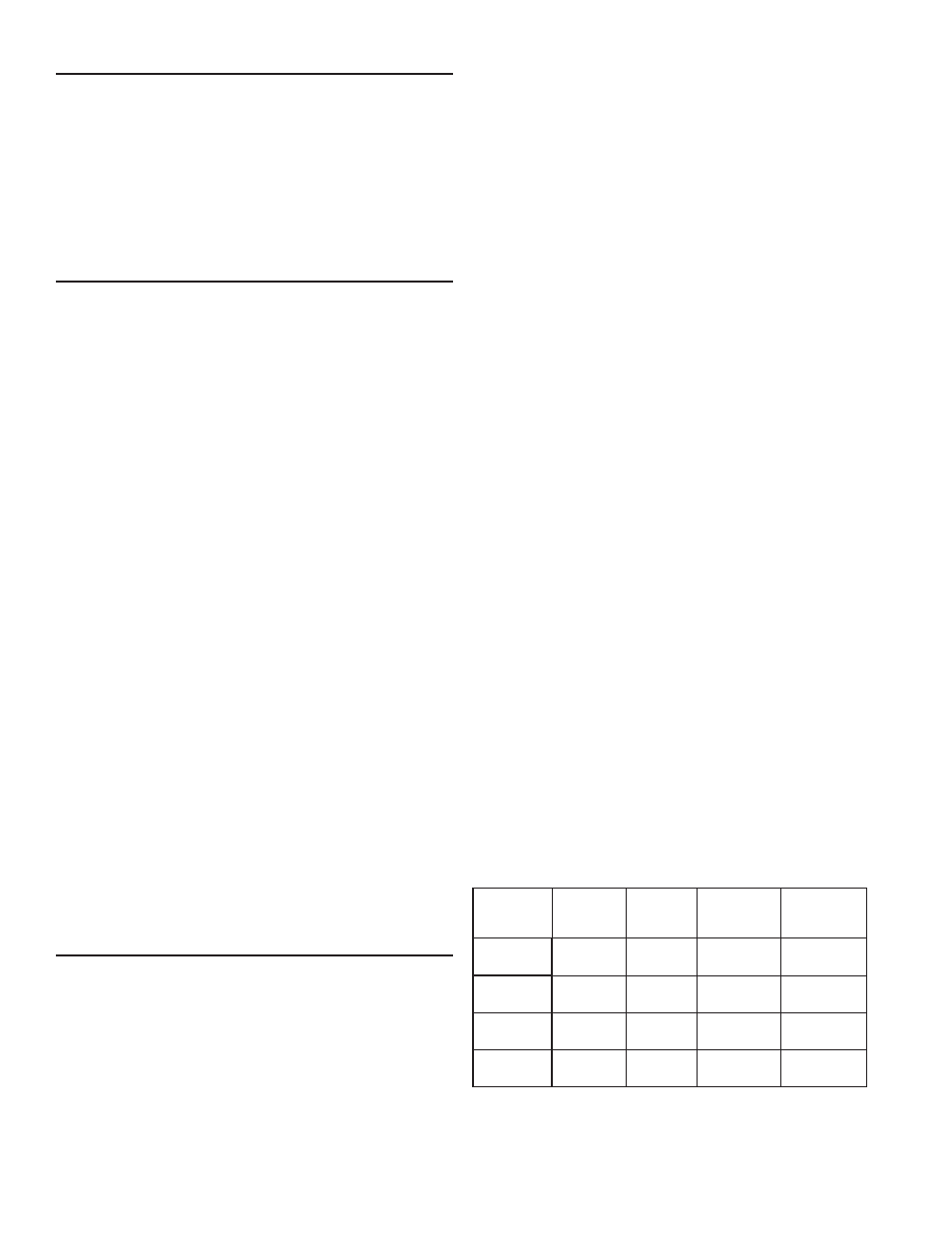

table 8.

approXimate time reQuired to consume

1 cu. ft. of gas at full capacity

input

rate

(btuh)

input

btuh

per

cu. ft.

times

(for natural

gas in sec.)

times

(for lp gas

in sec.)

GPG 81-140

140000

1050

2500

27. 2

64.7

GPG 81-199

199000

1050

2500

19.0

45.2

GPG 81-270

270000

1050

2500

14.0

33.3

GPG 81-370

370000

1050

2500

10.2.

24.3